Ultrasonic atomization reparation method of porous Li4Ti5O12 hollow spheres

An ultrasonic atomization and hollow sphere technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of difficult control of product particle size distribution, long sintering time, low production efficiency, etc., to improve high-current charging. Discharge performance and cycle performance, easy mass production, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

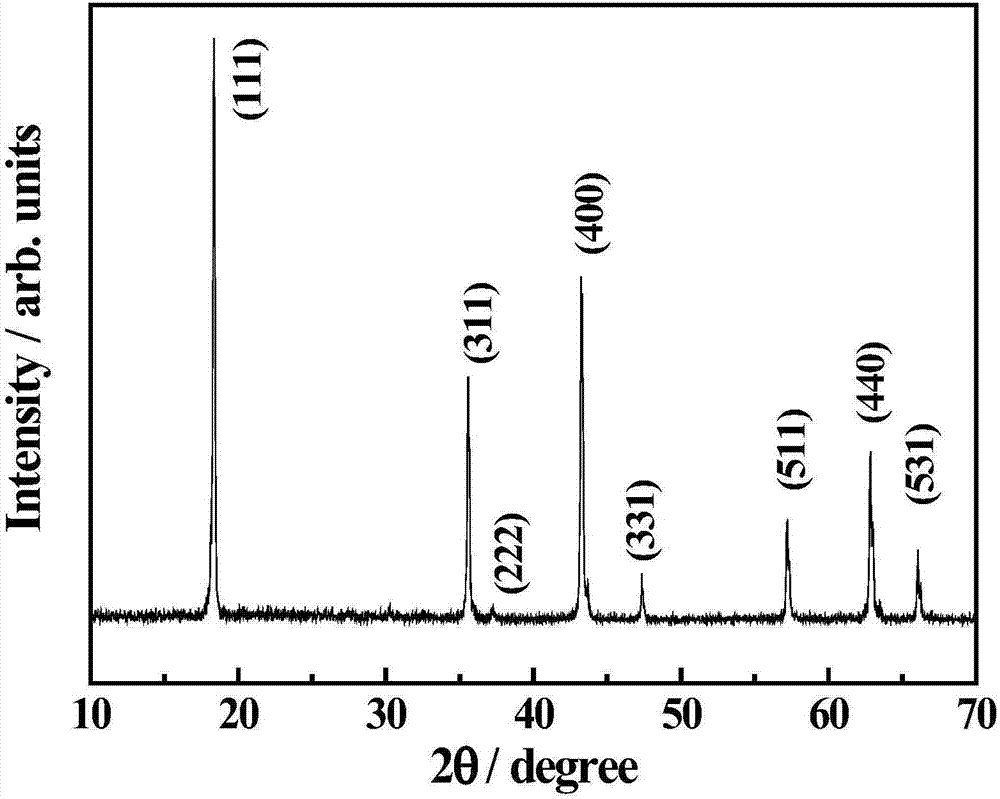

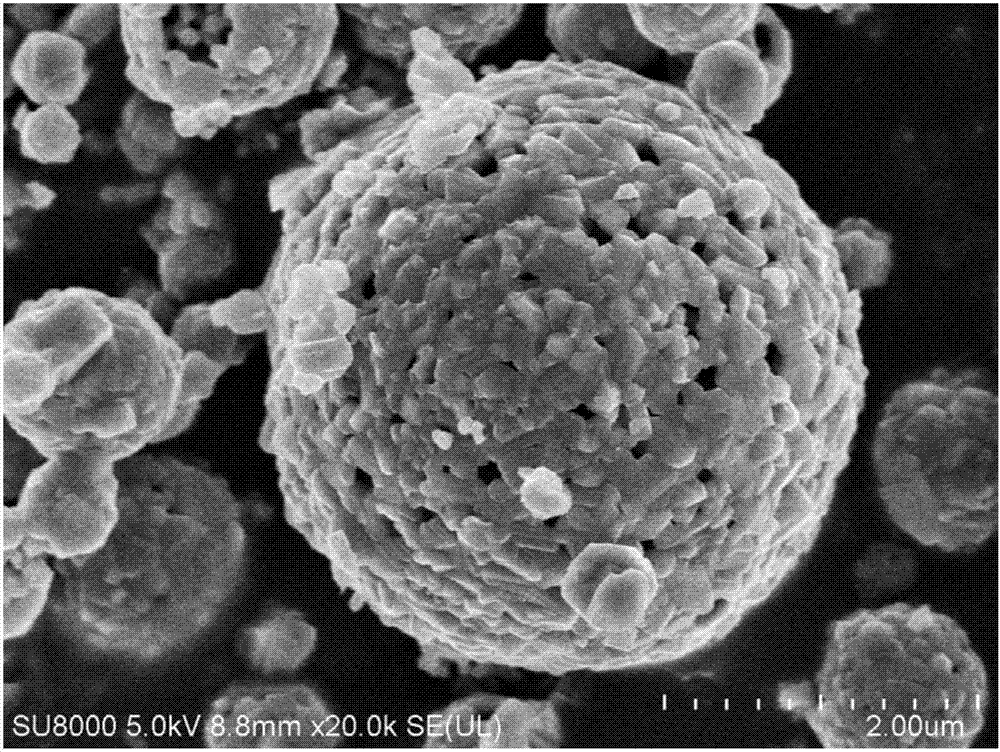

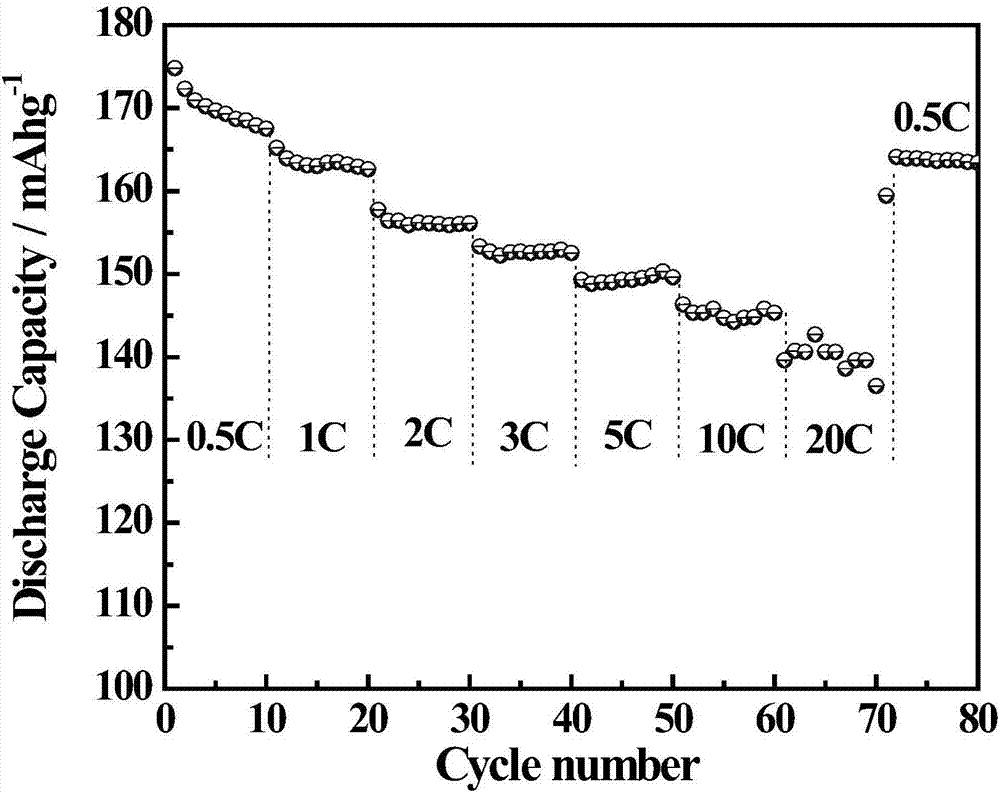

[0036] Hollow spherical hole Li 4 Ti 5 O 12

[0037] 3.32 g Li 2 CO 3 Dissolve in 20 ml of absolute ethanol, continue stirring at room temperature for 30 minutes, add 29.3 ml of isopropyl titanate dropwise, and continue to stir for 20 minutes to obtain A solution. Dissolve 25.2 grams of oxalic acid and 1.5 grams of sucrose in 400 milliliters of deionized water, and stir thoroughly to obtain a clear solution B; add solution A to solution B dropwise at a rate of 5 drops per second, and continue to stir for 1 hour. Mix the solution with the atomized precursor. The resulting solution was atomized with an ultrasonic atomization system with an oscillation frequency of 2.4MHz, the atomization volume was 0.2 ml per minute, and the atomized droplets produced were loaded into the tube furnace at a temperature of 600 ℃ by a vacuum pump. The moving speed of the drop in the quartz tube is 3 cm / s, and the dried precursor powder is collected by a powder collecting device.

[0038] The collected...

Embodiment 2

[0045] 3.24 g Li 2 CO 3 Dissolve in 30 ml of absolute ethanol, continue to stir at room temperature for 30 minutes, add 29.3 ml of isopropyl titanate dropwise, continue to stir for 30 minutes to obtain A solution. Dissolve 25.2 g of oxalic acid in 300 ml of deionized water, stir thoroughly to obtain a clear solution B; add solution A to solution B dropwise at a rate of 5 drops per second, and continue to stir for 2 hours to obtain an atomized solution Precursor mixed solution. The resulting solution is atomized with an ultrasonic atomization system with an oscillation frequency of 1.7MHz. The amount of atomization is 0.5 ml per minute. The resulting atomized droplets are loaded into a tube furnace at a temperature of 700℃ by a vacuum pump. The moving speed of the drop in the quartz tube is 5 cm / s, and the dried precursor powder is collected by a powder collecting device. The collected precursor powder was placed in a muffle furnace and calcined in an air atmosphere: the temper...

Embodiment 3

[0050] Dissolve 34 ml of butyl titanate in 50 ml of absolute ethanol, continue stirring at room temperature for 20 minutes, add 3 ml of glacial acetic acid dropwise, and continue to stir for 10 minutes to obtain a solution A. Dissolve 38.4 g of citric acid in 300 ml of deionized water, continue stirring at room temperature for 10 minutes, add 5.516 g of lithium nitrate, and continue to stir for 20 minutes to obtain a B solution. The A solution was added dropwise to the B solution at a dropping rate of 3 drops per second, and stirring was continued for 1 hour to obtain a precursor mixed solution for atomization. The resulting solution is atomized with an ultrasonic atomization system with an oscillation frequency of 1.7MHz. The atomization volume is 0.5 ml per minute. The resulting atomized droplets are loaded into a tube furnace at a temperature of 650℃ by a vacuum pump. The moving speed of the drop in the quartz tube is 5 cm / s, and the dried spherical lithium titanate precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com