Method for preparing Ag/ZnO/HA nanocomposite coating on titanium alloy

A nanocomposite coating and titanium alloy technology, applied in metal material coating technology, coating, medical science, etc., can solve problems such as bacterial infection, bacterial drug resistance, lack of antibacterial and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

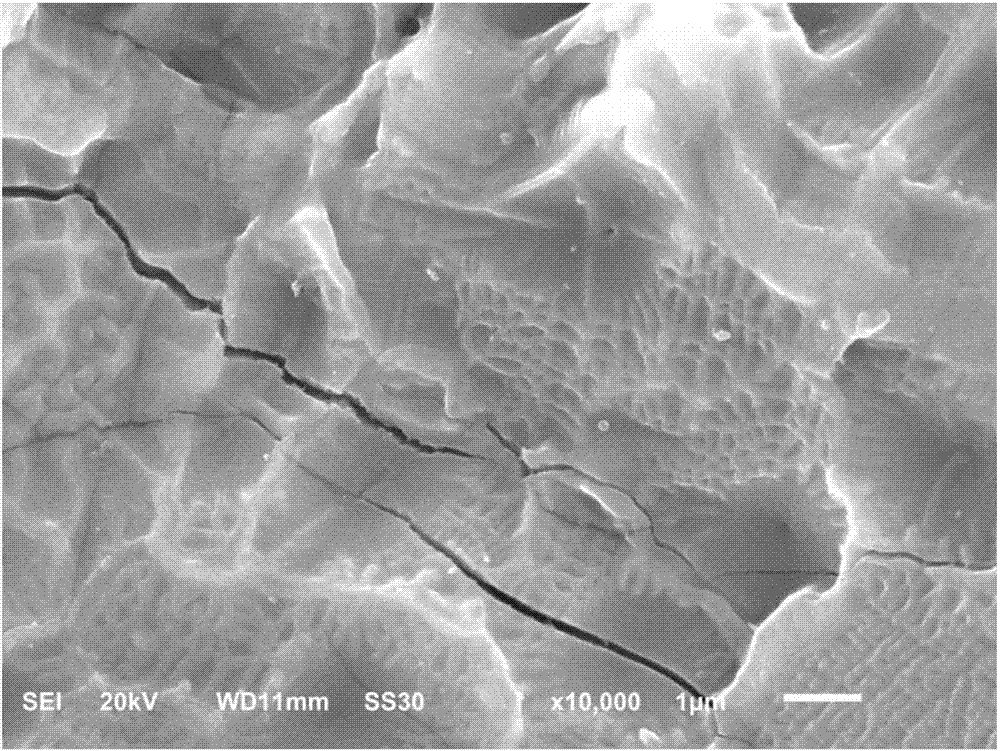

[0042] In this embodiment, the laser cladding treatment is directly carried out on the titanium alloy, and the steps include:

[0043] (1) Step 1: put Ti 6 Al 4 V was polished with 240-grit sandpaper to make Ti 6 Al 4 One side of V is mirror-like. Then, it was washed with ethanol and ultrasonicated 3 times, and then washed with deionized water and dried.

[0044] (2) Step 2: The laser cladding process uses a laser model JHM-1GY-300B. Turn on the laser two-dimensional platform to set the cladding parameters, set the current to I=100A, pulse width W=2ms, frequency f=20Hz, beam diameter D=0.6mm, operating speed V=5mm / s. Place the sample in the laser melting Overlay the platform, adjust the X-axis and Y-axis of the platform through the program, so that the sample is at the starting point of the laser emitter. Open the argon gas bottle to put the sample in the argon atmosphere, and start the "drive", "program control" and "program" systems on the control platform to carry out...

Embodiment 2

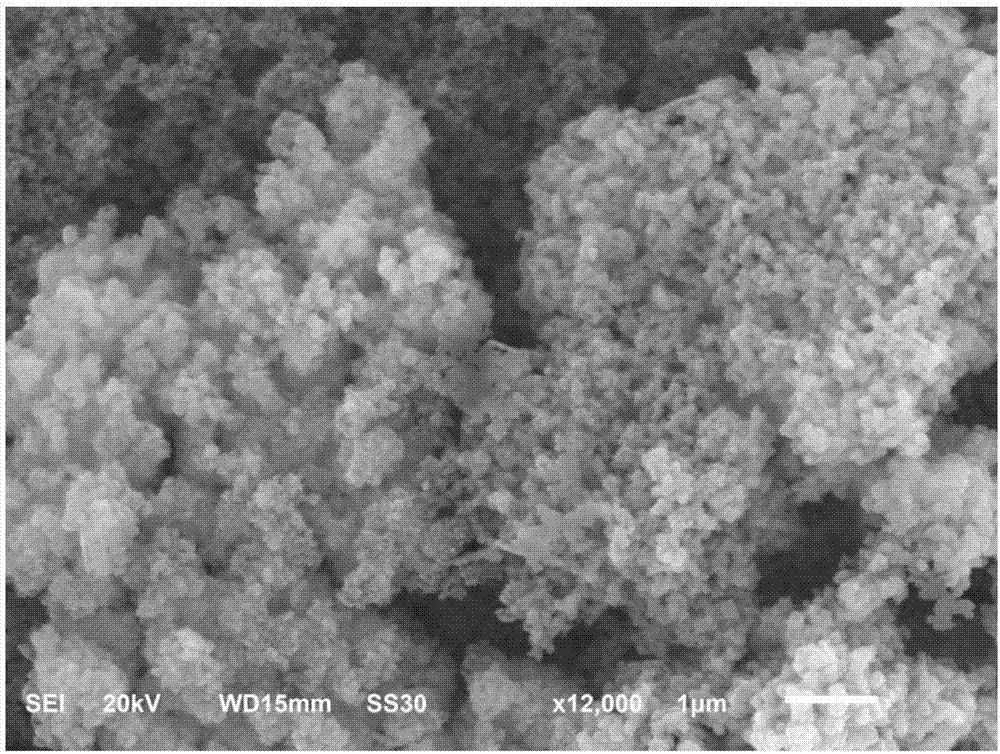

[0047] This embodiment provides a method for preparing Ag / ZnO / HA nanocomposite coating on titanium alloy, the steps include:

[0048] (1) Step 1: Weigh 135 mg of hydroxyapatite (HA) into a beaker filled with 10 mL of deionized water, and perform magnetic stirring after ultrasonication for 30 min. Weigh 11.81mg of silver nitrate crystals (AgNO 3 ) into another beaker, and add 10mL ammonia water to dissolve it, and wait for the AgNO 3 After completely dissolving in ammonia water, slowly pour the solution into a beaker containing HA solution and continue stirring. Then slowly add hydrazine hydrate (N 2 h 4 ), until the mixed solution changes from white to brown, stop adding N 2 h 4 , at this time AgNO 3 The silver ions in the solution are reduced to nano-silver simple substance.

[0049] (2) Step 2: Add 7.5 mg of zinc oxide nanoparticles (ZnO) to the above brown solution, perform suction filtration with an organic filter membrane, and wash with ethanol and deionized water ...

Embodiment 3

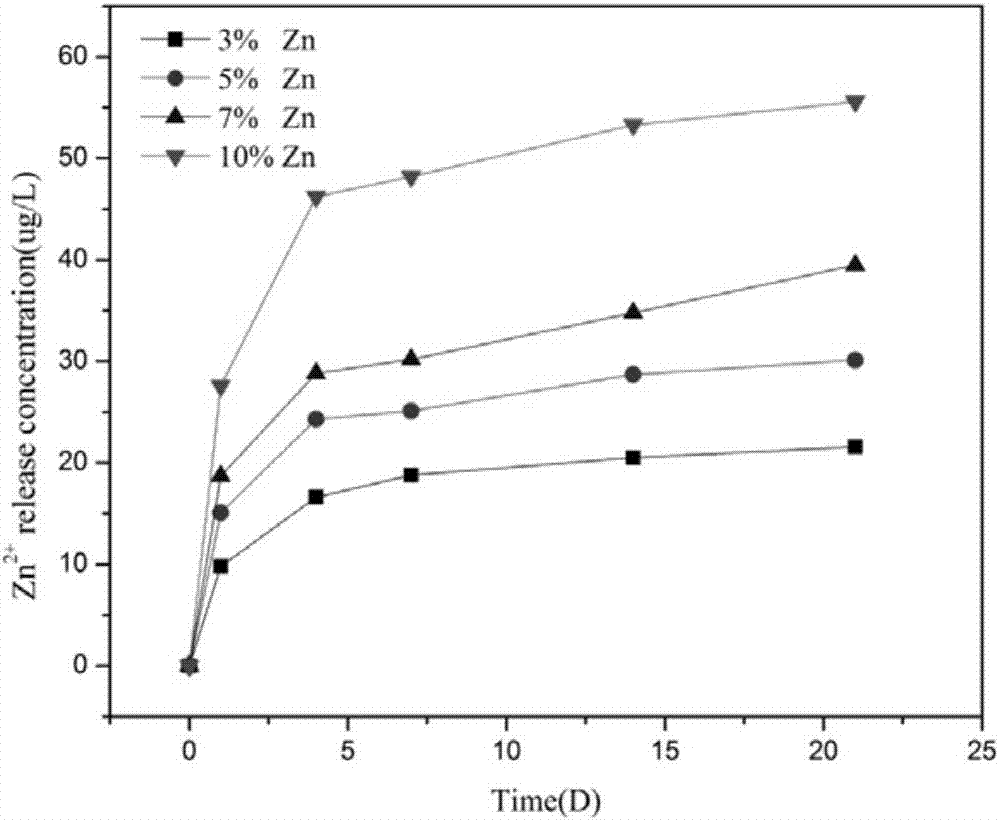

[0053] This embodiment provides a kind of method that prepares Ag / ZnO / HA nanocomposite coating on titanium alloy, and the titanium alloy with coating that this method obtains has carried out the test of the release concentration of zinc ion and silver ion, Specific steps include:

[0054] (1) Step 1: Weigh hydroxyapatite (HA) into a beaker filled with 10 mL of deionized water, and perform magnetic stirring after ultrasonication for 30 min. Weigh silver nitrate crystals (AgNO 3 ) into another beaker, and add 10mL ammonia water to dissolve it, and wait for the AgNO 3 After completely dissolving in ammonia water, slowly pour the solution into a beaker containing HA solution and continue stirring. Then slowly add hydrazine hydrate (N 2 h 4 ), until the mixed solution changes from white to brown, stop adding N 2 h 4 , at this time AgNO 3 The silver ions in the solution are reduced to nano-silver simple substance.

[0055] (2) Step 2: Add zinc oxide nanoparticles (ZnO) to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com