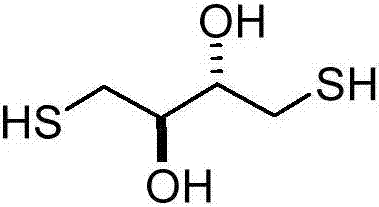

Preparation method of dithioerythritol (DTE)

A technology of dithioerythritol and dibutanol, which is applied in the field of compound preparation and achieves the effects of high yield, easily controllable conditions and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

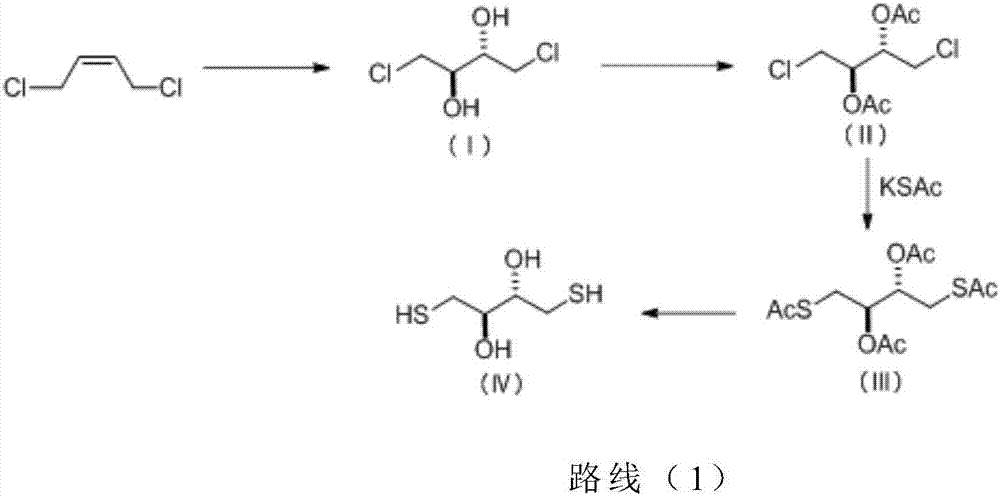

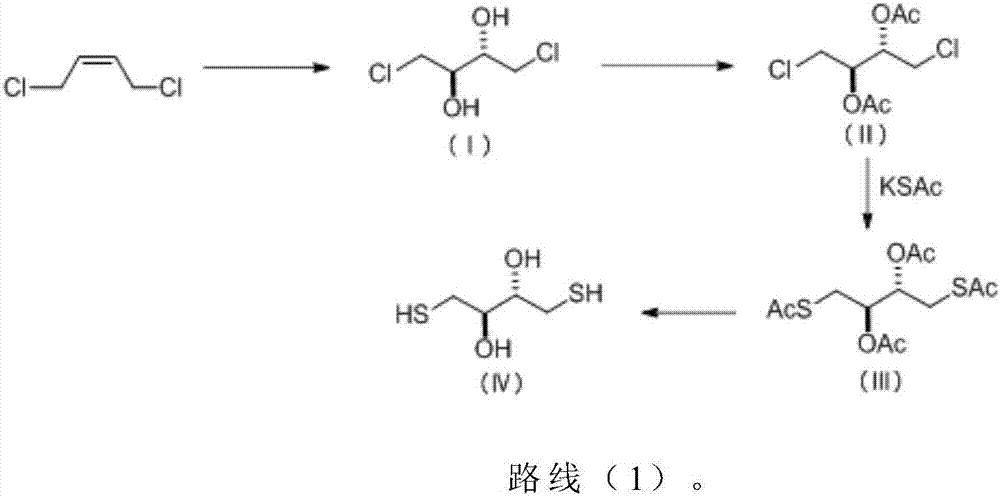

Method used

Image

Examples

Embodiment 1

[0043] Dissolve 10g of cis-1,4-dichloro-2-butene (Sinopharm Group Shanghai Chemical Reagent Company, chemically pure) in 60mL of acetone and 20mL of water in a three-necked flask, and drop it into ice water until the internal temperature of the system is 0°C- 5°C, add 15.16 g of potassium permanganate (Sinopharm Group Shanghai Chemical Reagent Company, chemically pure) in three batches. React for 5 hours, use TLC to monitor the complete reaction of the raw materials, remove the solids by suction filtration, add an appropriate amount of activated carbon to stir and then suction filter, distill off acetone under reduced pressure, add ethyl acetate, wash with saturated sodium chloride solution, separate the organic phase, anhydrous Dry over sodium sulfate, evaporate to dryness, and use ethyl acetate to petroleum ether volume ratio of 1:6 to raise temperature and reflux for beating and purification. 8.5 g of the product formula (I) 1,4-dichloro-2,3-dibutanol was obtained, with a y...

Embodiment 2

[0054] Dissolve 2g of formula (I) 1,4-dichloro-2,3-dibutanol in 20mL of dichloromethane in a one-mouth bottle, add 1.27g of triethylamine (Shanghai Chemical Reagent Company, Sinopharm Group, chemically pure), Add 2.8 mL of acetic anhydride (Sinopharm Shanghai Chemical Reagent Company, chemically pure) and heat to reflux (70° C.) for reaction under nitrogen protection. After 8 hours of reaction, TLC detected that the reaction of the raw materials was complete. Evaporate acetic anhydride, add ethyl acetate, wash with saturated sodium bicarbonate solution, wash with aqueous solution, separate the organic phase, dry over anhydrous sodium sulfate, evaporate to dryness, and use ethyl acetate and petroleum ether at a volume ratio of 1:5. Purification by beating. 2.15 g of 1,4-dichloro-2,3-diacetate of formula (II) was obtained with a yield of 71%.

[0055] 1 H NMR (400MHz, CDCl 3 ):δ=2.07(s,6H),3.61(dd,J=12.0,4.0Hz,2H),3.75(dd,J=12.0,4.0Hz,2H),5.25(s,2H).MS(ESI) :calculated for[...

Embodiment 3

[0063] Dissolve 5g of formula (II) 1,4-dichloro-2,3-diacetate in 20mL of N,N-dimethylformamide in a single-necked bottle, add 0.2g of sodium iodide (Sinopharm Shanghai Chemical Reagent Company, chemically pure), and then add 5.85g of potassium thioacetate (Sinopharm Shanghai Chemical Reagent Company, chemically pure), and heat to reflux (80-90° C.) for reaction. The reaction was carried out for 3 to 5 hours, and TLC detected that the reaction of the raw materials was complete. Add ethyl acetate, wash with water, separate the organic phase, decolorize with activated carbon for 1 hour, filter with suction, add anhydrous sodium sulfate to dry, and evaporate to dryness. 4.65 g of 1,4-dithioacetyl-2,3-acetate of formula (III) was obtained with a yield of 70%.

[0064] 1 H NMR: (500MHz, CDCl 3 ):δ=2.07(s,6H),2.36(s,6H),3.07(dd,J=14.0,6.5Hz,2H),3.11(dd,J=14.0,3.0Hz,2H),5.15(s, 2H).MS(ESI):calculated for [C 12 h 18 o 6 S 2 H] + (M+H) + requires m / z=323.06, found: 323.05.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com