Circulating fluidized-bed supercharged oxygen-enriched coal combustion device, and application thereof

A circulating fluidized bed and coal combustion technology, which is applied in the direction of fluidized bed combustion equipment, fuel burned in a molten state, and combustion methods, etc., to achieve the effects of increasing residence time, improving combustion efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

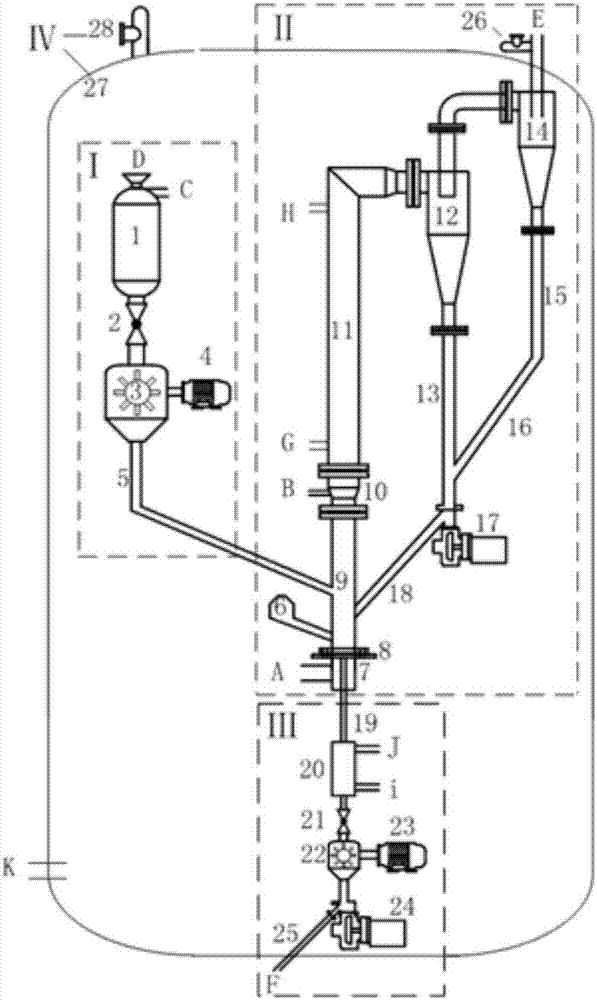

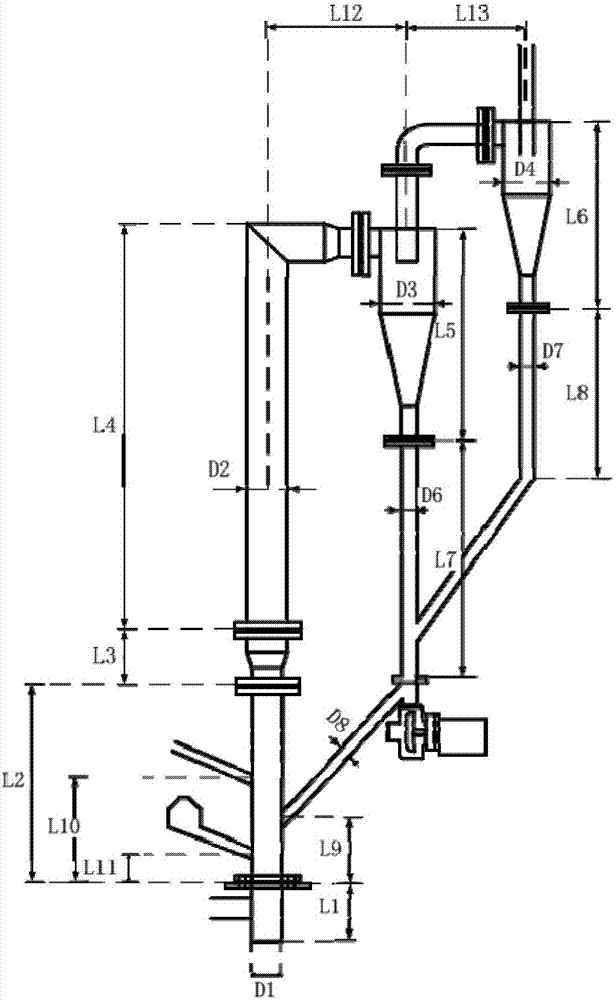

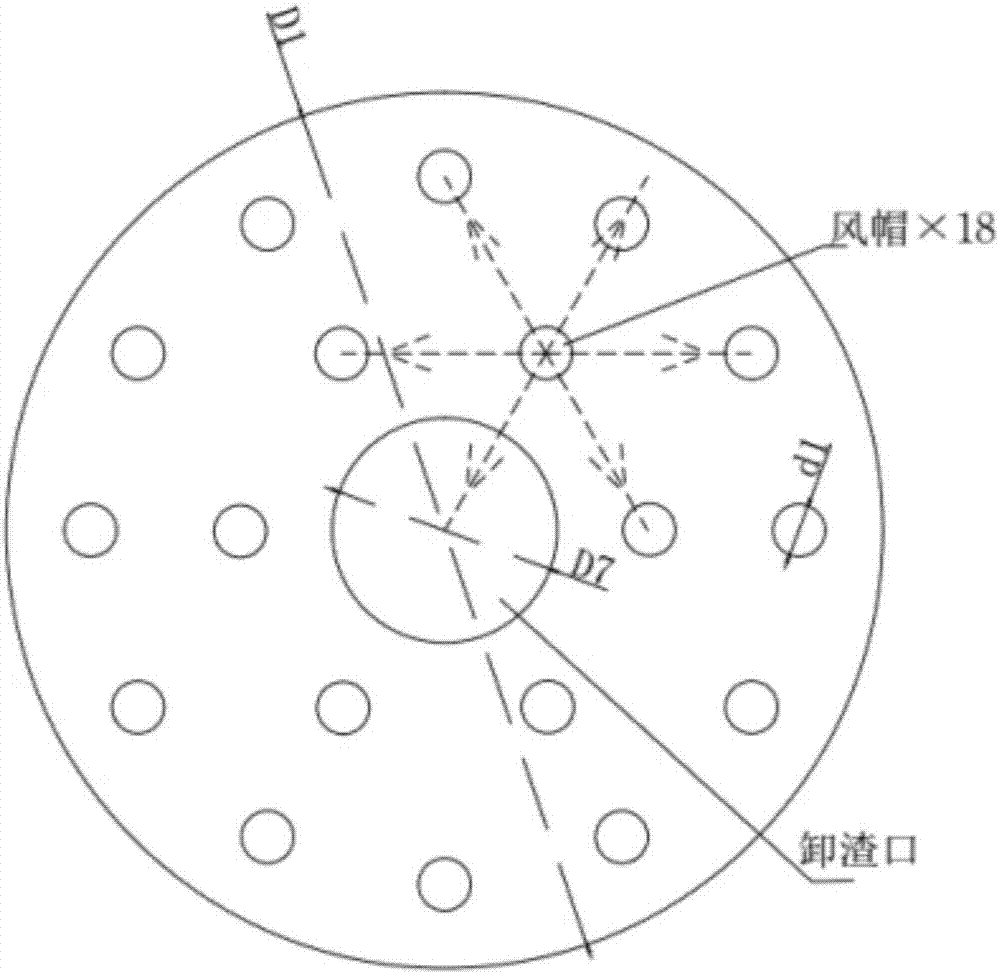

[0032] Such as figure 1 , a circulating fluidized bed pressurized oxygen-enriched coal combustion device, the device includes pressure feed system I, fluidized bed combustion reaction system II, pressure slag discharge system III and pressure shell IV four parts, of which the first three The systems are all within the pressure shell IV; the pressure feeding system I is, from top to bottom, the feed inlet D, the pressure supplement gas inlet C, the pressure hopper 1, the feed valve 2, the feed rotor 3 and the feed motor 4, Feed pipe 5; wherein, the feed inlet D is set directly above the pressure hopper 1, the pressure supplement gas inlet C is set at the upper end of the pressure hopper 1, and the outlet of the pressure hopper 1 is connected with the feed rotor 3 and the feed motor through the feed valve 2 The feed control device composed of 4 is connected to the inlet, and the feed pipe 5 at the outlet end of the feed control device is connected to the fluidized bed combustion...

Embodiment 2

[0042] Same as Example 1, when the operating pressure is high, the pressure shell can bear part of the pressure, thereby reducing the compressive stress borne by the materials of systems I, II, and III. At this time, the inside of the pressure shell is no longer normal pressure, but a pressure value between atmospheric pressure and the internal pressure of the fluidized bed. For example, when the internal operating pressure of the fluidized bed is 3Mpa, the pressure shell is filled with inert gas until the pressure is 1.5Mpa, so that the internal and external pressure difference is approximately equal to 1.5Mpa no matter at the wall of the fluidized bed or the pressure shell. The principle of pressure control is that the pressure inside the pressure shell is always half of the pressure inside the fluidized bed reactor, that is, the internal pressure of the pressure shell and the internal pressure of the fluidized bed rise slowly synchronously, the combustion temperature in the ...

Embodiment 3

[0045] Same as Example 1, for different coal types and particle sizes, the oxygen concentration in the primary air and the secondary air and the air volume ratio between them can be changed to maintain a good gas-solid flow and combustion state in the reactor. If the particle size of the fuel is large, the primary air volume can be appropriately increased to ensure the normal fluidization of the particles; when the fuel used is anthracite or other coal that is not easy to ignite or burn out, the oxygen content in the primary and secondary air can be increased. Optimize the combustion process. The oxygen volume fraction of the primary air in this embodiment is 35%, the oxygen volume fraction of the secondary air is 50%, and the rest is carbon dioxide. Among them, the primary wind is fluidized wind, accounting for 80% of the total air volume. The combustion temperature in the dense phase zone is 900-1000°C and the particle volume concentration is 0.35-0.45; the temperature in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap