Preparation method of compound microorganism bacterium agent for sludge treatment

A compound microbial agent and sludge treatment technology, applied in the direction of microbial-based methods, biochemical equipment and methods, biological sludge treatment, etc., can solve the problem of inactivation of bacterial flora physiological activity, cumbersome and complicated preparation process, complex flora Large inoculum volume and other problems, to achieve the effect of improving application activity, increasing the decomposition rate of organic matter, and improving domestication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

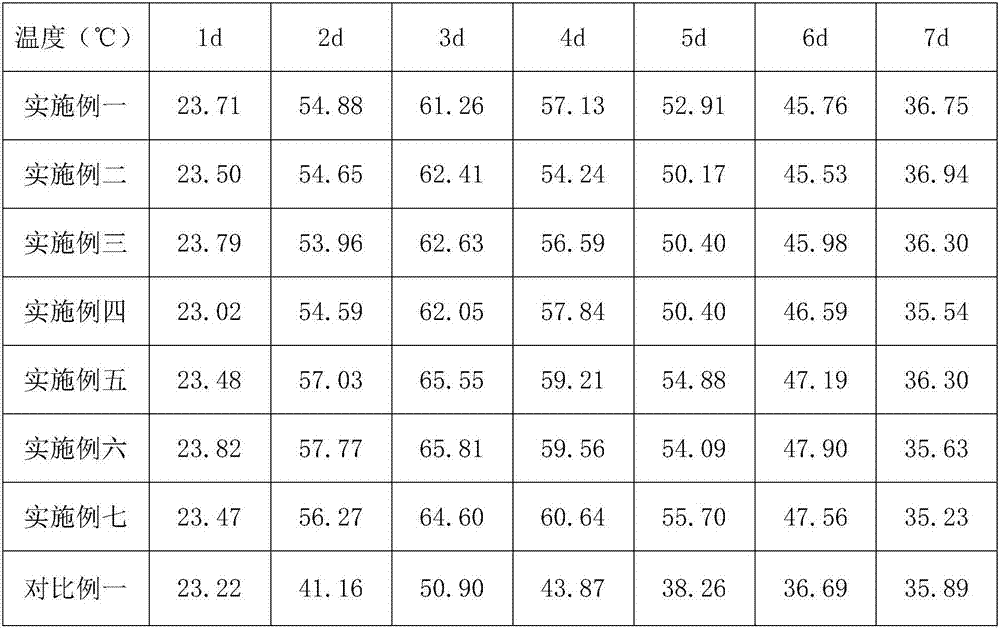

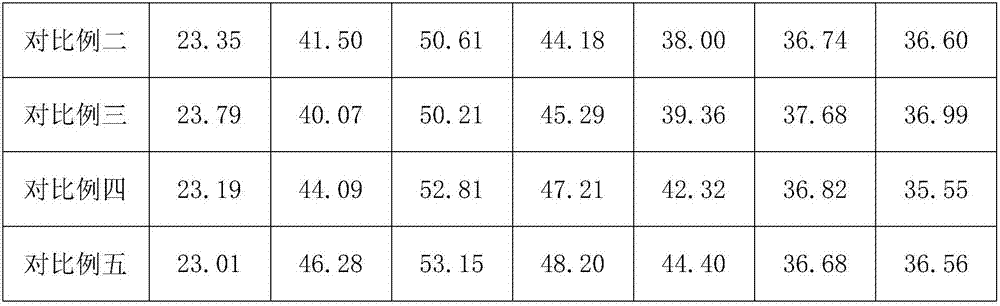

Examples

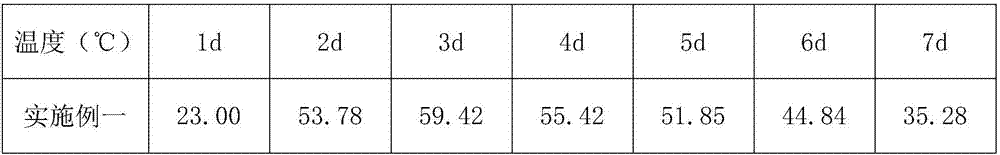

Embodiment 1

[0038] A method for preparing a composite microbial agent for sludge treatment, comprising mixing Escherichia coli, bacillus, sulfur oxidizing bacteria, actinomycetes, nitrifying bacteria and lactic acid bacteria to prepare a composite microbial agent;

[0039] Its preparation method comprises the following steps:

[0040] The first step: the cultivation of Escherichia coli and actinomycetes:

[0041] Weigh 15g of nutrient broth culture based on 500ml of distilled water, add 0.1g of tricyclodecanylamine solid, after shaking and stirring, put it into a vertical pressure steam sterilizer for sterilization and disinfection, turn on the ultra-clean workbench and turn on the ultraviolet light to sterilize for 10 minutes, After autoclaving, take out the culture medium and place it in the ultra-clean workbench, wait for the temperature of the culture medium to drop to about 60°C, inoculate E. Bacteria, then put into a biochemical incubator and adjust the temperature of the incubator...

Embodiment 2

[0049] A preparation method for sludge treatment composite microbial bacterial agent, comprising the following steps:

[0050] The first step: the cultivation of Escherichia coli and actinomycetes:

[0051] Weigh 15g of nutrient broth culture based on 500ml of distilled water, add 1g of tricyclodecanylamine solid, after shaking and stirring, put it into a vertical pressure steam sterilizer for sterilization, turn on the ultra-clean workbench and turn on the ultraviolet light to sterilize for 20min, wait for After high-pressure sterilization, take out the culture medium and place it in the ultra-clean workbench, wait for the temperature of the culture medium to drop to about 70°C, inoculate E. coli into the culture medium under aseptic conditions, inoculate the E. , then put it into a biochemical incubator and adjust the temperature of the incubator to 38°C, and incubate for 10 hours;

[0052] The second step: the cultivation of bacillus and lactic acid bacteria:

[0053] Wei...

Embodiment 3

[0059] A preparation method for sludge treatment composite microbial bacterial agent, comprising the following steps:

[0060] The first step: the cultivation of Escherichia coli and actinomycetes:

[0061] Weigh 15g of nutrient broth culture based on 500ml of distilled water, add 0.1g of tricyclodecanylamine solid, after shaking and stirring, put it into a vertical pressure steam sterilizer for sterilization and disinfection, turn on the ultra-clean workbench and turn on the ultraviolet light for 20 minutes of sterilization, After autoclaving, take out the culture medium and place it in the ultra-clean workbench, wait for the temperature of the culture medium to drop to about 60°C, inoculate E. Bacteria, then put into a biochemical incubator and adjust the temperature of the incubator to 38°C, and incubate for 8 hours;

[0062] The second step: the cultivation of bacillus and lactic acid bacteria:

[0063] Weigh 15g of nutrient broth based on 500ml of distilled water, shake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com