Method for modifiying aluminium alloy bipolar plate used for proton exchange membrane fuel cell by boron nitride nano sheet

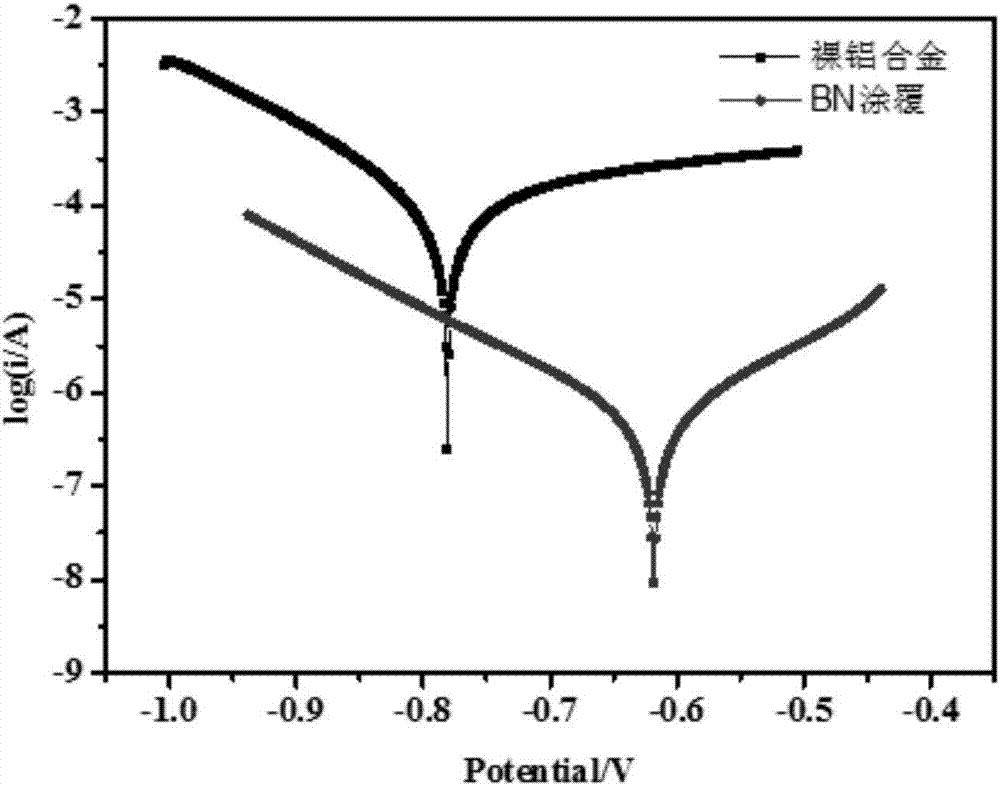

A proton exchange membrane and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, nanotechnology, etc., can solve the problems of large chemical reagent preparation process, power consumption, environmental pollution, etc., achieve excellent corrosion resistance, improve corrosion resistance Corrosion performance, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A boron nitride (BN) nanosheet modified proton exchange membrane fuel cell (PEMFC) aluminum alloy bipolar plate, comprising the steps of:

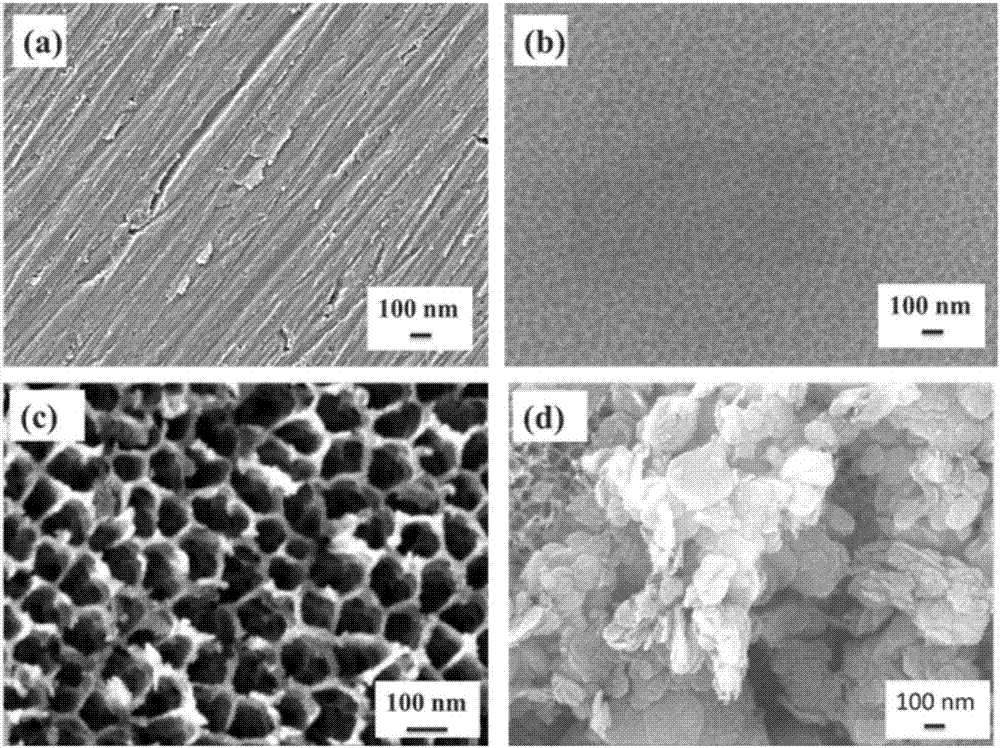

[0044] (1) Aluminum alloy surface pretreatment: Two pieces of aluminum alloy 5052 (①, ②) are polished by 1#, 3#, 6# metallographic sandpaper in turn. Put the ② sample at V 乙醇 :V HClO4 =4:1 in the solution (volume ratio), the electrochemical polishing time is 3min with a voltage of 20V, and the solution temperature is controlled at 3°C.

[0045] (2) Anodizing treatment: oxidize the ② sample treated in (1) at a phosphoric acid concentration of 0.2M at a voltage of 30V for 40min, and control the solution temperature at 50°C.

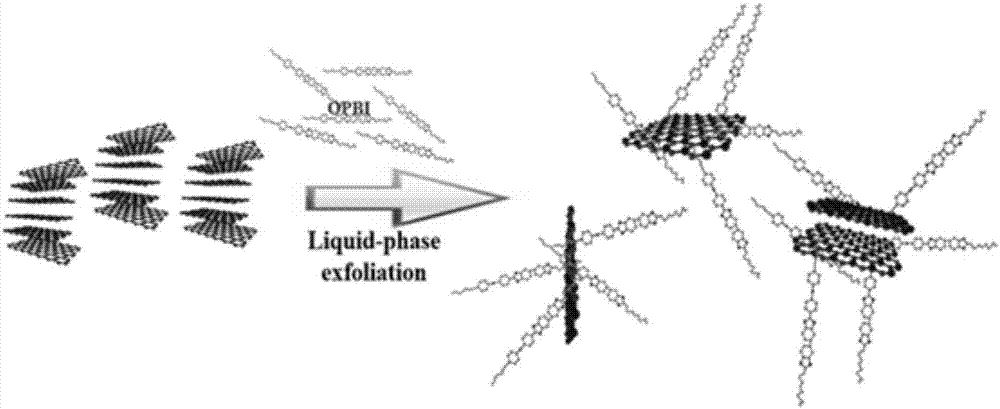

[0046] (3) see figure 1 As shown, the preparation process of BN nanosheets is: first prepare 0.5g / L polybenzimidazole (OPBI) dimethyl sulfoxide (DMSO) solution, and then add a certain amount of hexagonal boron nitride powder to a certain volume of OPBI The DMSO solution (the content of BN is 0.5mg / ml) was ult...

Embodiment 2

[0057] A boron nitride (BN) nanosheet modified proton exchange membrane fuel cell (PEMFC) aluminum alloy bipolar plate, comprising the steps of:

[0058] (1) Aluminum alloy surface pretreatment: Two pieces of aluminum alloy 6061 (①, ②) are polished by 1#, 3#, 6# metallographic sandpaper in turn. Put the ② sample at V 乙醇 :V HClO4 =4:1 in the solution (volume ratio), the electrochemical polishing time is 3min with a voltage of 20V, and the solution temperature is controlled at 3°C.

[0059] (2) Anodizing treatment: oxidize the ② sample treated in (1) at a phosphoric acid concentration of 0.2M at a voltage of 30V for 40min, and control the solution temperature at 50°C.

[0060] (3) The preparation process of BN nanosheets is as follows: first prepare 0.5g / L polybenzimidazole (OPBI) dimethyl sulfoxide (DMSO) solution, and then add a certain amount of hexagonal boron nitride powder to a certain volume of OPBI The DMSO solution (the content of BN is 0.5mg / ml) was ultrasonically s...

Embodiment 3

[0067] A boron nitride (BN) nanosheet modified proton exchange membrane fuel cell (PEMFC) aluminum alloy bipolar plate, comprising the steps of:

[0068] (1) Aluminum alloy surface pretreatment: Two pieces of aluminum alloy 5052 (①, ②) are polished by 1#, 3#, 6# metallographic sandpaper in turn. Put the ② sample at V 乙醇 :V HClO4 =4:1 in the solution (volume ratio), the electrochemical polishing time is 3min with a voltage of 20V, and the solution temperature is controlled at 3°C.

[0069] (2) Anodizing treatment: The ② sample treated in (1) was oxidized at a concentration of 0.2M phosphoric acid at a voltage of 30V for 10 minutes, and the temperature of the solution was controlled at 50°C.

[0070] (3) The preparation process of BN nanosheets is as follows: first prepare 0.5g / L polybenzimidazole (OPBI) dimethyl sulfoxide (DMSO) solution, and then add a certain amount of hexagonal boron nitride powder to a certain volume of OPBI The DMSO solution (the content of BN is 0.5mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com