Catalyst for degrading phenol by adsorption-catalytic oxidation synergy and preparation method and application thereof

A technology of synergistic degradation and catalytic oxidation, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of poor timeliness, high reaction temperature and high treatment cost of wastewater treatment, It achieves the effects of remarkable catalytic degradation effect, simple preparation method and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

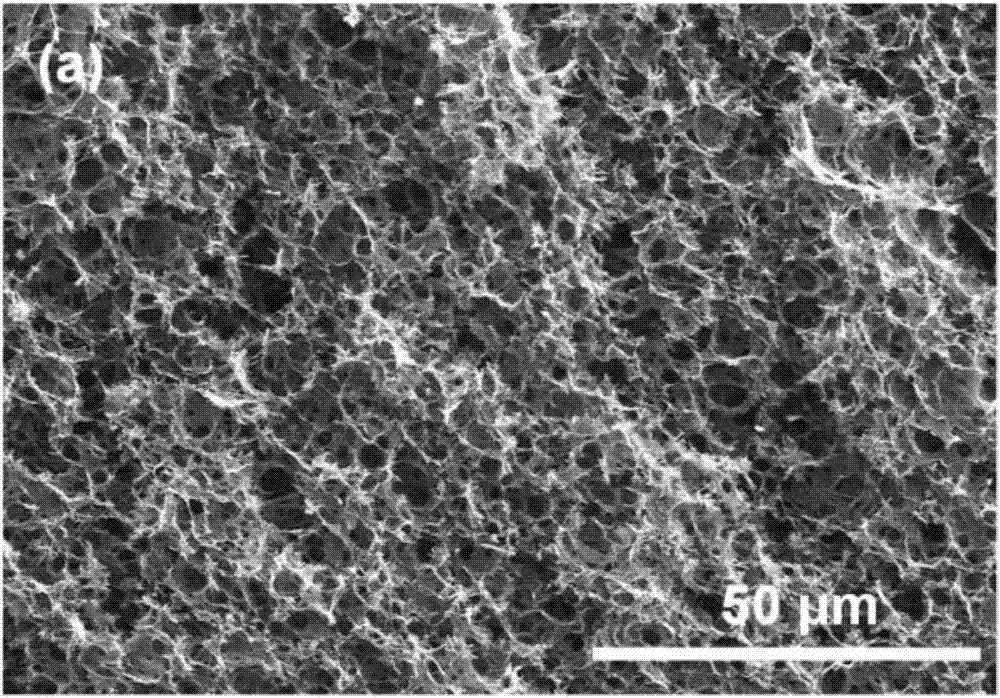

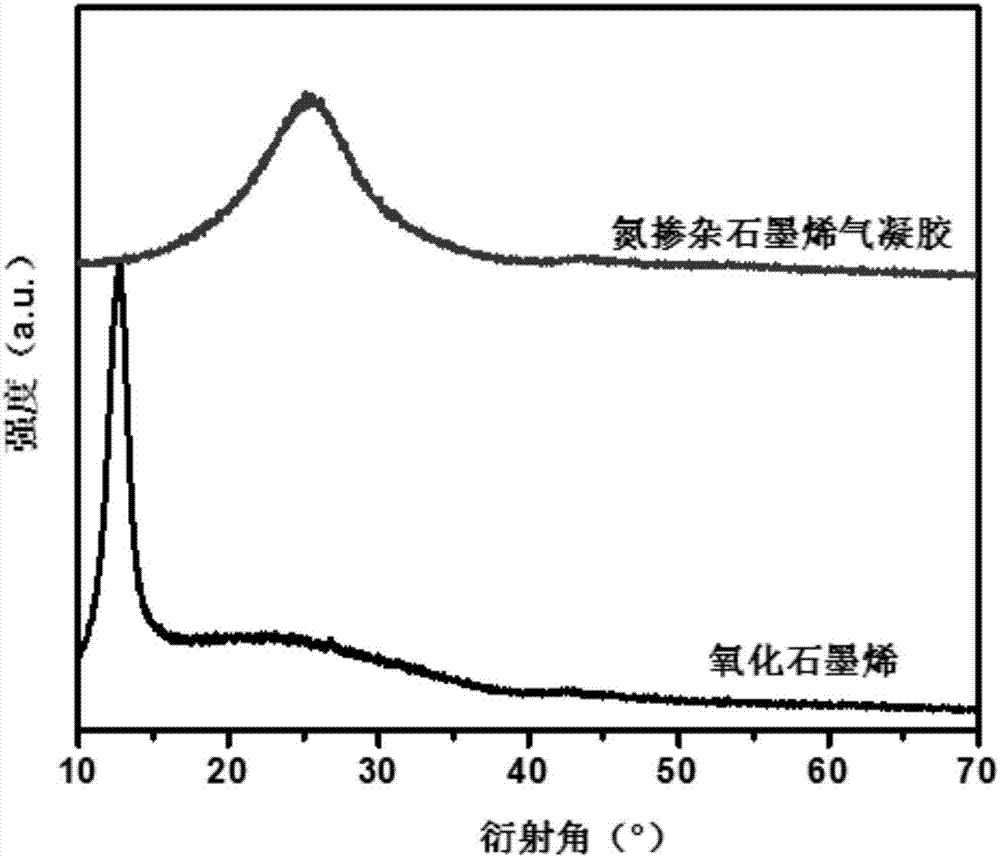

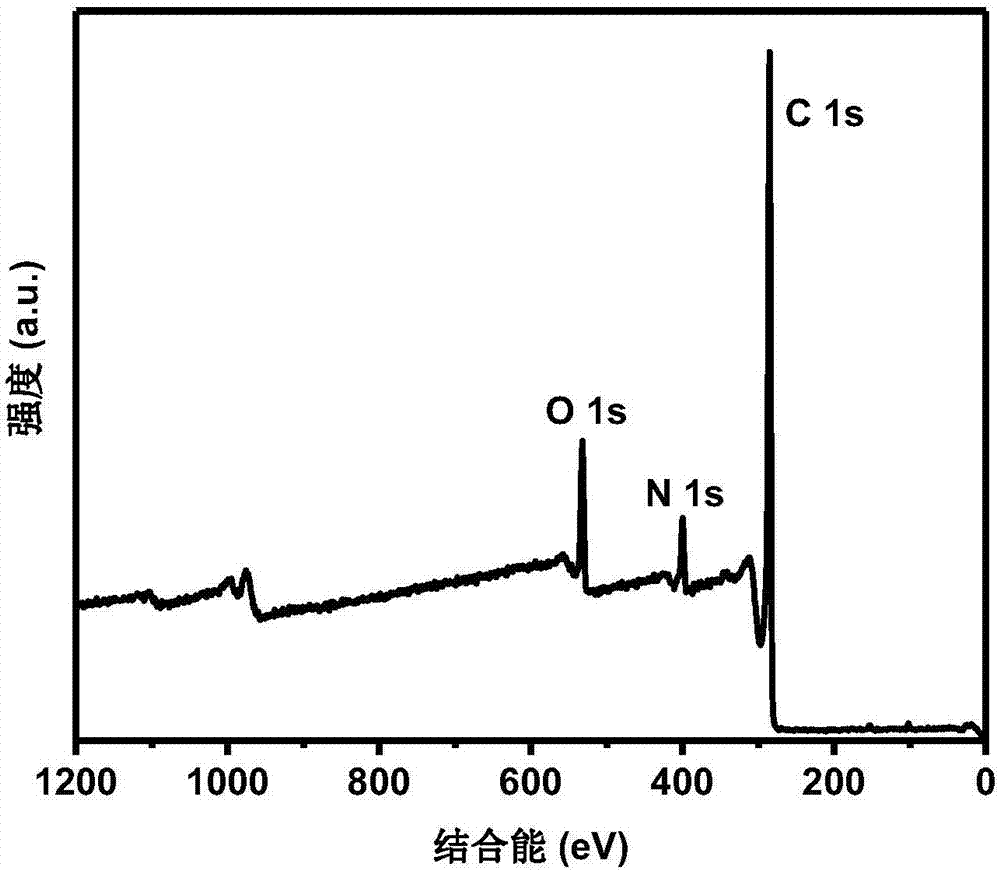

[0051] A preparation method of a catalyst for adsorption-catalytic oxidation synergistically degrading phenol, comprising the following steps:

[0052](1) Using expanded graphite as a carbon source to prepare graphene oxide; the specific preparation method is: slowly add 18g of potassium permanganate and 3g of sodium nitrate to 138ml of concentrated sulfuric acid at 0°C in an ice bath, and simultaneously use 500rpm Mechanical stirring at a high speed, after the potassium permanganate and sodium nitrate are completely dissolved, slowly add 3g of expanded graphite, after the expanded graphite is completely stirred evenly, seal it and place it in the refrigerator, and keep it warm at 0°C for 24h; then transfer the reaction system to Stir and react in a constant temperature oil bath at 35°C for 30 minutes, then slowly add deionized water dropwise while raising the temperature, and add a total of 300ml of deionized water dropwise, at this time the temperature just rises to 98°C, kee...

Embodiment 2

[0073] A preparation method of a catalyst for adsorption-catalytic oxidation synergistically degrading phenol, comprising the following steps:

[0074] (1) Using expanded graphite as a carbon source to prepare graphene oxide; the specific preparation method is: slowly add 18g of potassium permanganate and 3g of sodium nitrate to 138ml of concentrated sulfuric acid at 0°C in an ice bath, and simultaneously use 200rpm Mechanical stirring at a high speed, after the potassium permanganate and sodium nitrate are completely dissolved, slowly add 3g of expanded graphite, after the expanded graphite is completely stirred evenly, seal it and place it in the refrigerator, and keep it warm at 0°C for 24h; then transfer the reaction system to Stir and react in a constant temperature oil bath at 35°C for 30 minutes, then slowly add deionized water dropwise while raising the temperature, and add a total of 300ml of deionized water dropwise, at this time the temperature just rises to 98°C, ke...

Embodiment 3

[0082] A preparation method of a catalyst for adsorption-catalytic oxidation synergistically degrading phenol, comprising the following steps:

[0083] (1) Using expanded graphite as a carbon source to prepare graphene oxide; the specific preparation method is: slowly add 18g of potassium permanganate and 3g of sodium nitrate to 138ml of concentrated sulfuric acid at 0°C in an ice bath, and simultaneously use 300rpm Mechanical stirring at a high speed, after the potassium permanganate and sodium nitrate are completely dissolved, slowly add 3g of expanded graphite, after the expanded graphite is completely stirred evenly, seal it and place it in the refrigerator, and keep it warm at 0°C for 24h; then transfer the reaction system to Stir and react in a constant temperature oil bath at 35°C for 30 minutes, then slowly add deionized water dropwise while raising the temperature, and add a total of 300ml of deionized water dropwise, at this time the temperature just rises to 98°C, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com