Method for preparing lithium carbonate through fluorinating and calcining spodumene and extracting lithium

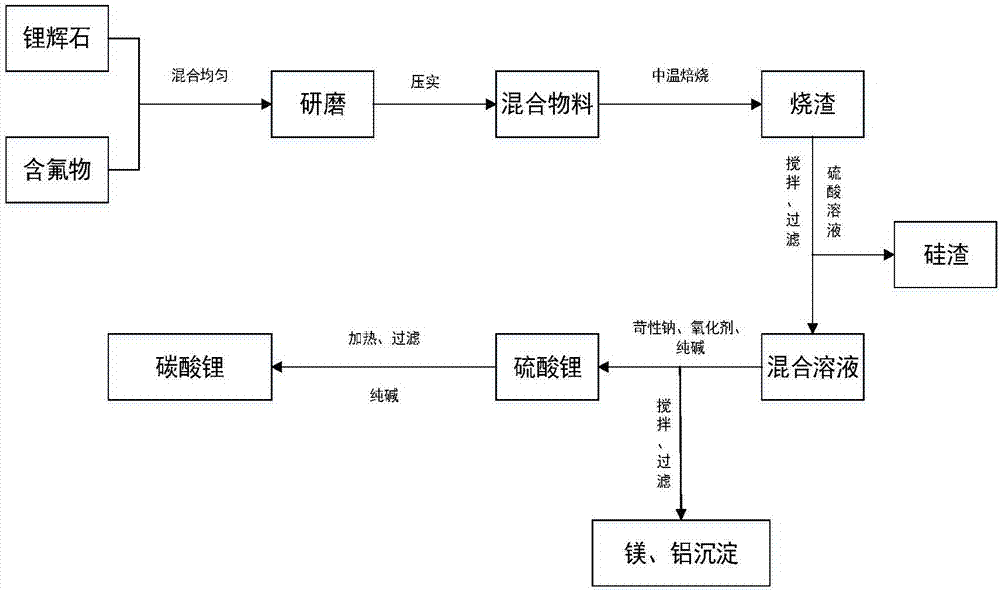

A technology of spodumene and lithium carbonate, applied in the field of spodumene, can solve the problems of high energy consumption and low utilization rate of ore, and achieve the effect of high product purity, suitable for large-scale production and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: mixed material roasting process

[0032]Take 20.029g of spodumene particles and 29.4g of ammonium fluoride (1.0 times the theoretical amount), mix the materials evenly, grind to 100 mesh and compact. Put the mixed material into a muffle furnace, heat up to 300°C for 30 minutes, and roast for 3 hours to obtain 20.746 g of solid slag, which is a secondary ore that removes a large amount of silica and exposes lithium oxide; SiO 2 Content 20.847% (SiO in raw ore 2 Content 59.607%).

[0033] Take 30.060g of spodumene particles, 61.745g of a mixture of ammonium fluoride and lithium fluoride (1.4 times the theoretical amount), mix the materials evenly, grind to 100 mesh and compact. Put the mixed material into the muffle furnace, raise the temperature to 300°C for 30 minutes, and roast for 3 hours to obtain 35.273 g of solid slag; SiO 2 Content 21.393% (SiO in raw ore 2 Content 59.607%), F content is 42.583%.

[0034] Take 20.029g of spodumene particles and ...

Embodiment 4

[0037] Embodiment 4: the preparation technology of lithium sulfate solution

[0038] Take 10g of secondary ore roasted at 400°C for 3 hours with 1.2 times the theoretical amount of ammonium fluoride, but it cannot be wetted well and forms mud, so the next experiment cannot be carried out.

[0039] Take 10g of secondary ore roasted at 400°C for 3h with 1.2 times the theoretical amount of ammonium fluoride, add 30mL of distilled water, and stir at room temperature for 1h; successively wash the slag and filter to obtain a lithium sulfate solution with a lithium oxide leaching rate of 4.43%.

[0040] Take 10 g of secondary ore roasted at 400°C for 3 h with 1.2 times the theoretical amount of ammonium fluoride, add 50 mL of distilled water, and stir for 1 h at room temperature; successively wash the slag and filter to obtain a lithium sulfate solution with a lithium oxide leaching rate of 4.17%.

[0041] Take 10g of secondary ore roasted at 400°C for 3h with 1.2 times the theoretic...

Embodiment 7

[0048] Embodiment 7: the preparation technology of lithium carbonate product

[0049] Take 200mL of lithium sulfate mother liquor with a lithium content of 421.9μg / ml, heat and concentrate, and continue heating to 85°C, add sodium hydroxide solution, stir while adding, and measure the pH of the solution with pH test paper; when pH=7, continue Add saturated sodium carbonate solution to pH = 10; filter while hot to remove the formed Fe and Mg precipitates, keep the temperature at 85°C, and add sodium carbonate particles until pH = 14, centrifuge for 10 minutes to obtain the crude lithium carbonate product, after drying Sent for component detection, the purity of lithium carbonate was 96.4%.

[0050] In the above embodiments, the raw materials can be ground by a ball mill. The ball mill adopts LGB04 omnidirectional planetary ball mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com