An industrial waste water and waste gas treatment system

A wastewater treatment system and waste gas treatment technology, applied in multi-stage water treatment, water/sewage treatment, aerobic process treatment, etc., can solve the problems of water environment pollution, toxic and harmful, complex composition, etc., achieve high treatment efficiency, reduce Pollution, broad-spectrum applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

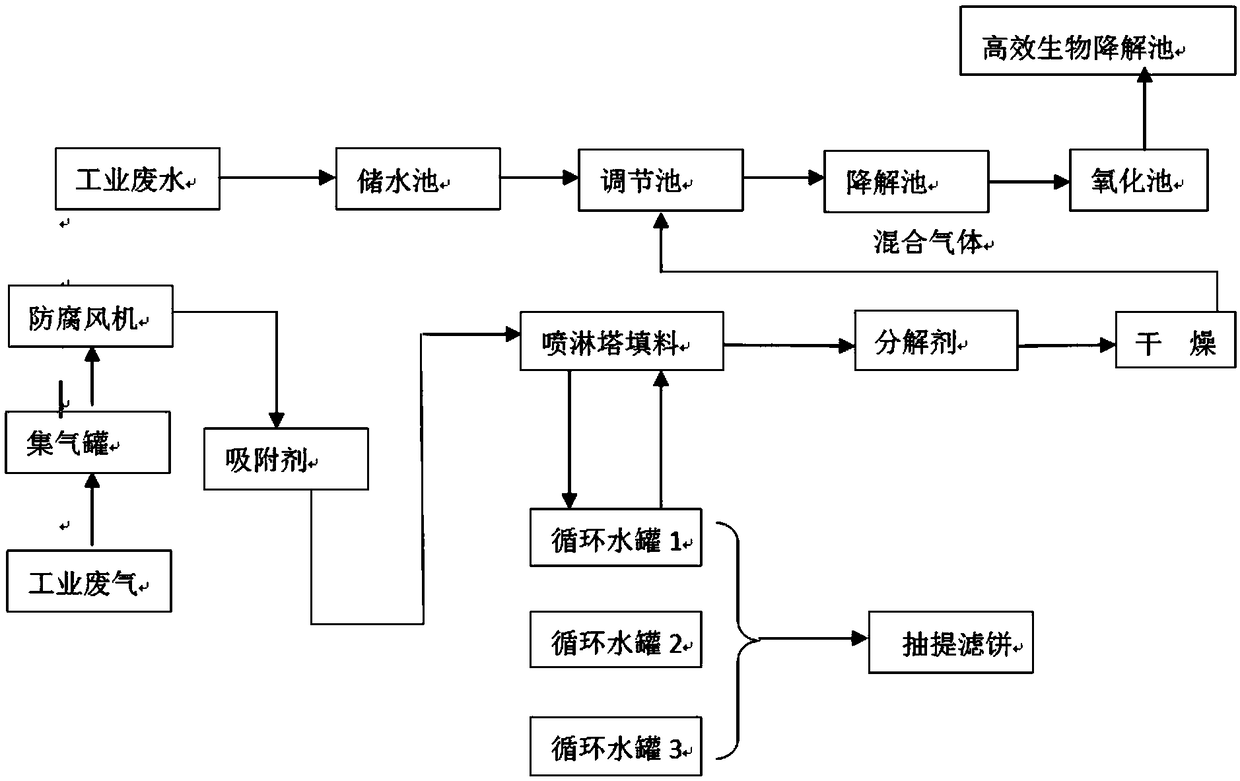

[0044] Embodiment 1: A kind of waste gas, waste water treatment system

[0045] A biopharmaceutical Co., Ltd., the waste gas and waste water discharged repeatedly failed to meet the standards, and the nitrogen oxide emission was 0.075mg / m 3 , the emission of sulfur dioxide is 0.018mg / m 3, The total amount of waste water produced is 1.1 cubic meters, the aerobic effluent is between COD400-800mg / L, and the external drainage COD is between 200-400mg / L, which is difficult to reach the local standard of COD<50mg / L; after the present invention, the transformation is as follows:

[0046] The exhaust gas treatment system steps include:

[0047] (1) Use the gas collection tank to collect industrial waste gas, and the purpose of adding the collection tank is to ensure the stability of the air flow;

[0048] (2) the waste gas of step (1) is adsorbed by calcium oxide;

[0049] (3) Pass the waste gas into the spray tower for spraying again, the spraying reagent is 10% sodium hydroxide, ...

Embodiment 2

[0059] Embodiment 2: A kind of waste gas, waste water treatment system

[0060] A Chinese medicine pharmaceutical Co., Ltd., the waste gas and waste water discharged repeatedly failed to meet the standards, and the hydrogen chloride discharge was 1.48mg / m 3 , the total amount of waste water produced is 7,000 cubic meters, the aerobic effluent is between COD300-600mg / L, and the external discharge COD is between 150-420mg / L, which is difficult to reach the standard of local COD<50mg / L; after the present invention, the transformation is as follows:

[0061] The exhaust gas treatment system steps include:

[0062] (1) Use the gas collection tank to collect industrial waste gas, and the purpose of adding the collection tank is to ensure the stability of the air flow;

[0063] (2) the waste gas of step (1) is adsorbed by calcium oxide;

[0064] (3) waste gas is passed into the spray tower to spray again, the spray reagent is 10% sodium hydroxide, and the intake velocity of the hyd...

Embodiment 3

[0074] Embodiment 3: A kind of waste gas, waste water treatment system

[0075] A chemical group Co., Ltd., the waste gas and waste water discharged repeatedly failed to meet the standards, the hydrogen sulfide discharge was 0.01mg / m3, the hydrogen chloride discharge was 1.98mg / m3, the total waste water production was 17,000 cubic meters, and the aerobic effluent was COD200-500mg / m3. L, between the COD of external drainage 100-220mg / L, it is difficult to reach the standard of local COD<50mg / L; After the present invention is transformed as follows:

[0076] The exhaust gas treatment system steps include:

[0077] (1) Use the gas collection tank to collect industrial waste gas, and the purpose of adding the collection tank is to ensure the stability of the air flow;

[0078] (2) the waste gas of step (1) is adsorbed by calcium oxide;

[0079] (3) Waste gas is passed into the spray tower to spray again, the spray reagent is 10% sodium hydroxide, and the intake velocity of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com