Expansive type halogen-free flame-retardant ethylene propylene diene monomer material

A EPDM and intumescent technology, applied in the field of polymer materials, can solve the problems of affecting the electrochemical performance of materials, low flame retardant efficiency, poor compatibility, etc., and achieve good practical value, promotion prospects, and flame retardant effects. Good, improve the effect of carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Set the temperature of the mill at 50°C, add 100 parts of EPDM, 2 parts of zinc stannate, 2 parts of zinc hydroxystannate, 1.5 parts of pentaerythritol stearate (PETS), 2.5 parts Zinc oxide, 0.5 part of stearic acid, 0.5 part of anti-aging agent 2-mercaptobenzimidazole (MB), 0.5 part of anti-aging agent N, N'-di(β-naphthyl)-p-phenylenediamine (DNP), and finally add 2 Part of triallyl isocyanurate (TAIC-P), 0.2 part of bis-tert-butylperoxycumene (BIPB 40B) until mixed evenly to obtain a rubber compound. The mixed rubber was placed on a flat vulcanizer and vulcanized at 160°C for 15 minutes to obtain the halogen-free flame-retardant EPDM material.

Embodiment 2

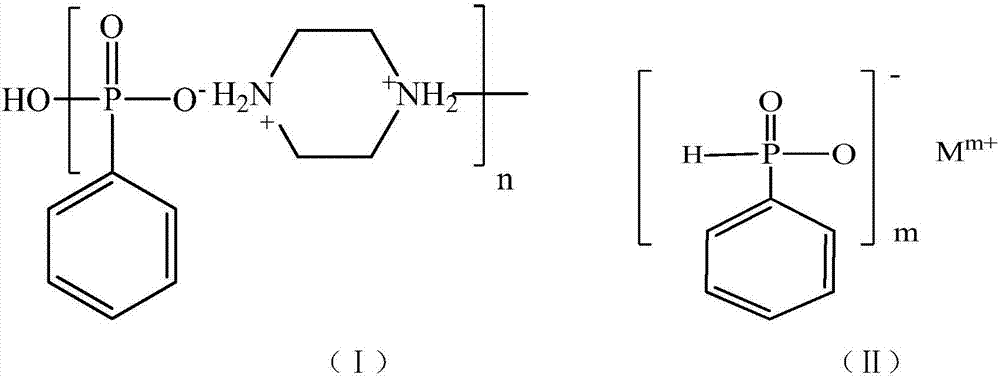

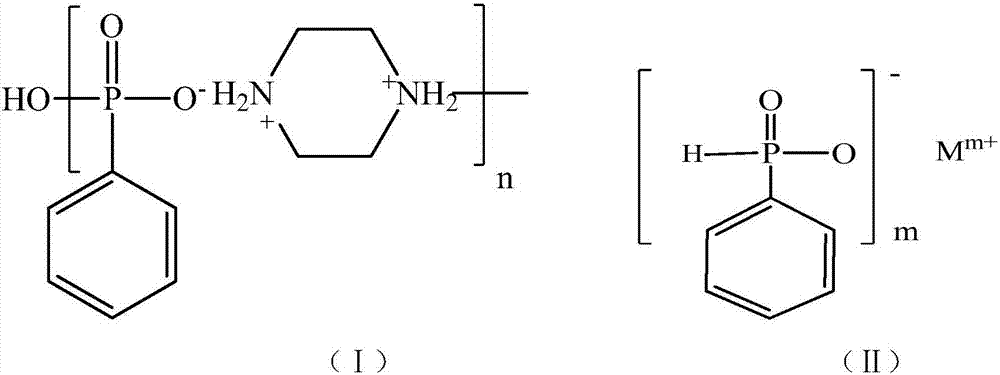

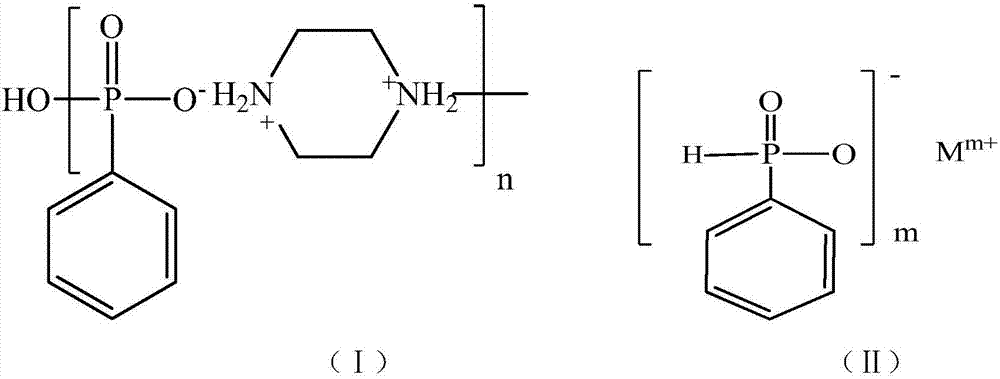

[0028] Set the temperature of the mill to 50°C, add 50 parts of EPDM, 50 parts of piperazine polyphenylphosphonate, 2 parts of zinc stannate, 2 parts of zinc hydroxystannate, 1.5 parts of PETS, 2.5 parts of zinc oxide, 0.5 parts 1 part of stearic acid, 0.5 part of antiaging agent MB, 0.5 part of antiaging agent DNP, and finally add 2 parts of TAIC-P and 0.2 part of BIPB 40B until mixed evenly to obtain a rubber compound. The mixed rubber was placed on a flat vulcanizer and vulcanized at 160°C for 15 minutes to obtain the halogen-free flame-retardant EPDM material.

Embodiment 3

[0030] Set the temperature of the mill at 50°C, add 50 parts of EPDM, 50 parts of aluminum phenylphosphinate, 2 parts of zinc stannate, 2 parts of zinc hydroxystannate, 1.5 parts of PETS, 2.5 parts of zinc oxide, 0.5 parts Stearic acid, 0.5 part of anti-aging agent MB, 0.5 part of anti-aging agent DNP, and finally add 2 parts of TAIC-P and 0.2 part of BIPB 40B until mixed evenly to obtain a rubber compound. The mixed rubber was placed on a flat vulcanizer and vulcanized at 160°C for 15 minutes to obtain the halogen-free flame-retardant EPDM material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com