Ultralow-temperature lithium ion battery composite positive electrode material and preparation method thereof

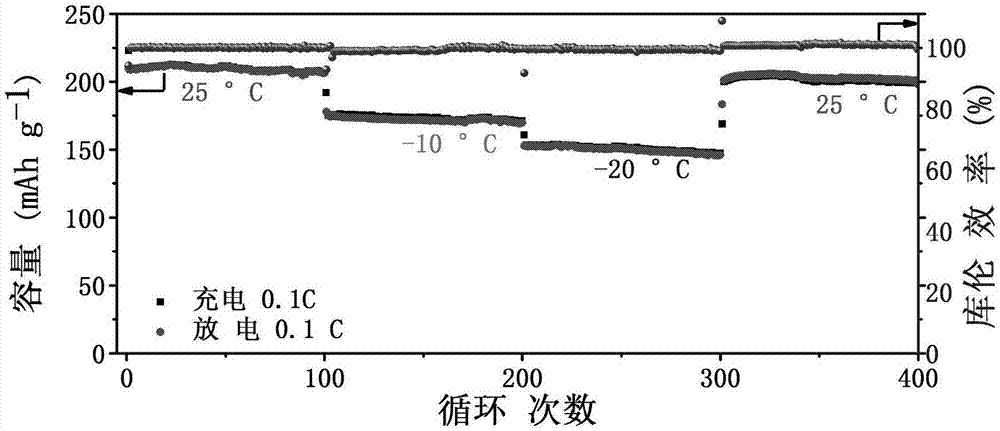

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor low-temperature performance of lithium-ion batteries and cannot meet the market demand of electric vehicles, and achieve excellent low-temperature performance and high Coulombic efficiency , the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing an ultra-low temperature lithium-ion battery composite positive electrode material, comprising the following steps:

[0036] Step 1: preparing nickel cobalt lithium manganese oxide positive electrode material;

[0037] Step 2: adding the nickel-cobalt lithium manganese oxide cathode material obtained in step 1 into the polymer material solution and stirring to obtain a composite cathode material for an ultra-low temperature lithium-ion battery;

[0038] The polymer material solution is one or more of polypyrrole, polyaniline, diazonium salt, polyethylene dioxythiazide / polyethylene glycol solution; the diazonium salt is preferably heavy tetrafluoroborate Azobenzene.

[0039] According to the present invention, the preparation method of described nickel cobalt lithium manganese oxide positive electrode material preferably comprises:

[0040] (1) Dissolve nickel salt, cobalt salt, and manganese salt in deionized ...

Embodiment 1

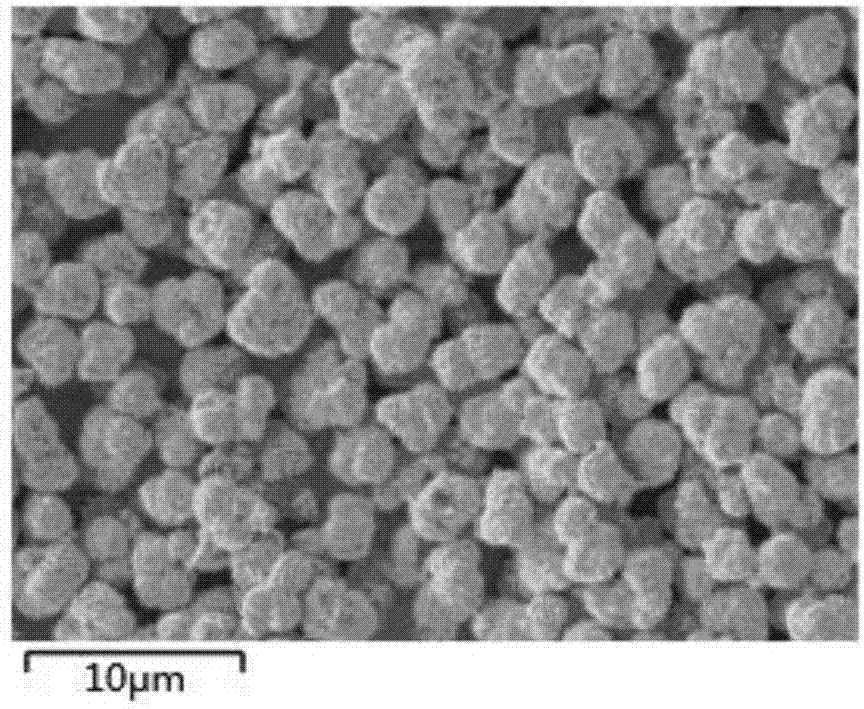

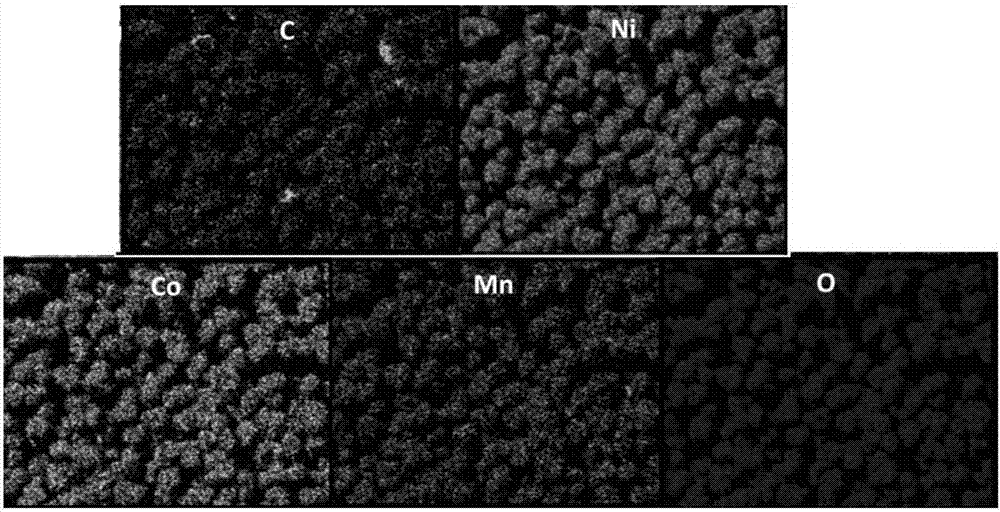

[0055] Weigh nickel sulfate, cobalt sulfate, and manganese sulfate respectively in a molar ratio of 6:2:2, and dissolve them in deionized water to prepare a total concentration of 2mol / L, and pass an inert gas to remove oxygen for 30 minutes; prepare 4mol / L sodium hydroxide as Precipitating agent, 2mol / L ammonia water as complexing agent, pass N 2 Remove oxygen for 40 minutes; prepare a 2mol / L ammonia solution as the bottom liquid and first add it to the reaction kettle, and pass N at the same time 2 As a protective gas, under mechanical stirring, the nickel-cobalt-manganese salt solution is added to the reaction kettle at a rate of 2L / h by means of a metering pump, and the mixed solution of the precipitant and complexing agent is added dropwise, and the reaction system is precisely controlled The pH value is 11.5, the reaction temperature is 50°C, and the stirring speed is 900r / min. Co-precipitation reaction is carried out, and finally a brownish-yellow solid-liquid mixture i...

Embodiment 2

[0061] Weigh nickel chloride, cobalt chloride, and manganese chloride respectively in a molar ratio of 5:2:3, and dissolve them in deionized water to prepare a total concentration of 1.5mol / L, and pass an inert gas to remove oxygen for 60 minutes; prepare 4mol / L L sodium hydroxide is used as precipitating agent, 2mol / L ammonia water is used as complexing agent, pass N 2 Remove oxygen for 60 minutes; prepare 2mol / L ammonia aqueous solution as the bottom liquid and first add it to the reaction kettle, and pass N 2 As a protective gas, under mechanical stirring, the nickel-cobalt-manganese salt solution is added to the reaction kettle at a dropping rate of 1L / h by means of a metering pump, and the mixed solution of the precipitating agent and complexing agent is added dropwise, and the reaction system is precisely controlled. The pH value is 11.3, the reaction temperature is 60°C, and the stirring speed is 1000r / min. Co-precipitation reaction is carried out, and finally a light b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com