Plating method of high silicon aluminum alloy

A high-silicon aluminum alloy, plating solution technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of low yield of shell materials, uneven metal coating, unstable product performance, etc. , to ensure the performance of the coating, reduce the production cost, and eliminate the internal stress of the nickel layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Plating of high-silicon aluminum alloy with a silicon content of 27%.

[0082] 1) Degreasing. Put the high-silicon aluminum alloy with a silicon content of 27wt% after machining in an acetone solution at room temperature to clean and remove oil for 10 minutes, and dry at room temperature;

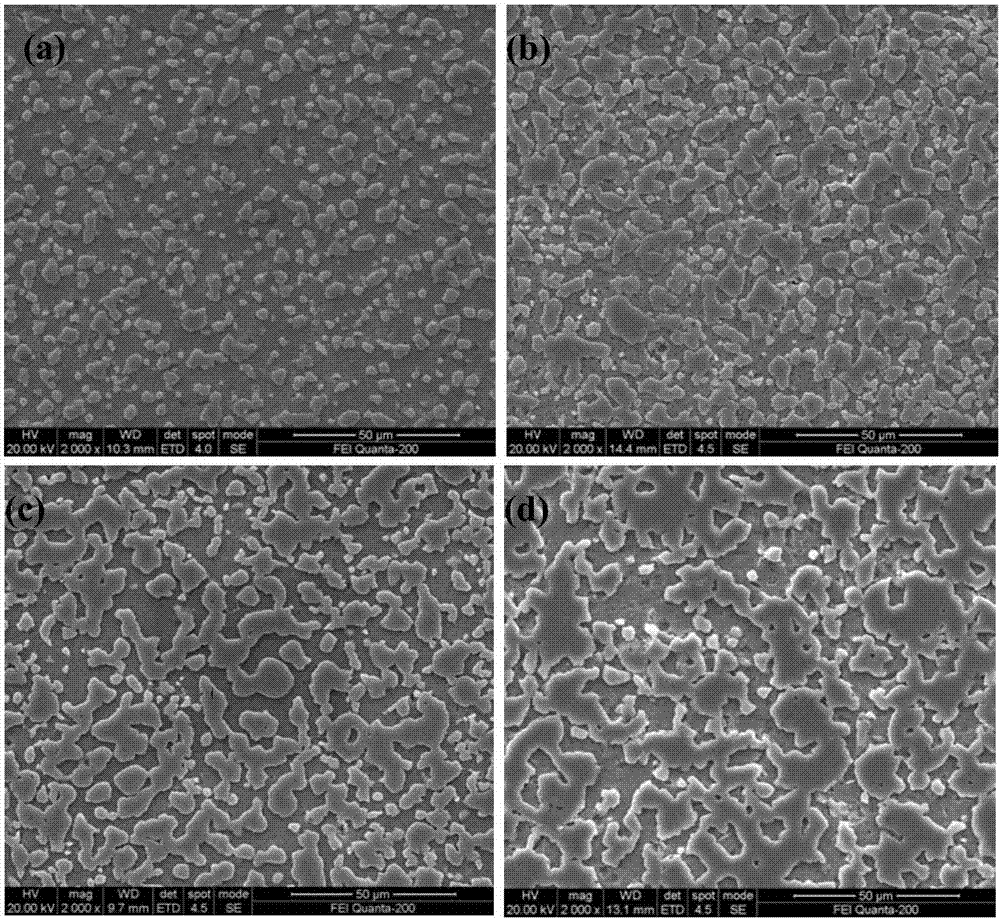

[0083] 2) coarsening. The formula is 300ml / L of nitric acid, 100ml / L of hydrofluoric acid, 100ml / L of hydrogen peroxide and water. , washed with clean water, then ultrasonically washed for 20 minutes, and dried in a 60°C drying oven;

[0084] 3) Once activated. The formula is nickel acetate 60g / L, sodium dihydrogen phosphate 80g / L and water. The mixed solution is 1L. The activation solution is heated to 160°C. During the activation process, the fluctuation does not exceed 5°C. Gently shake in the oven for 10 minutes, take it out, wash it with water, and dry it in a 60°C drying oven;

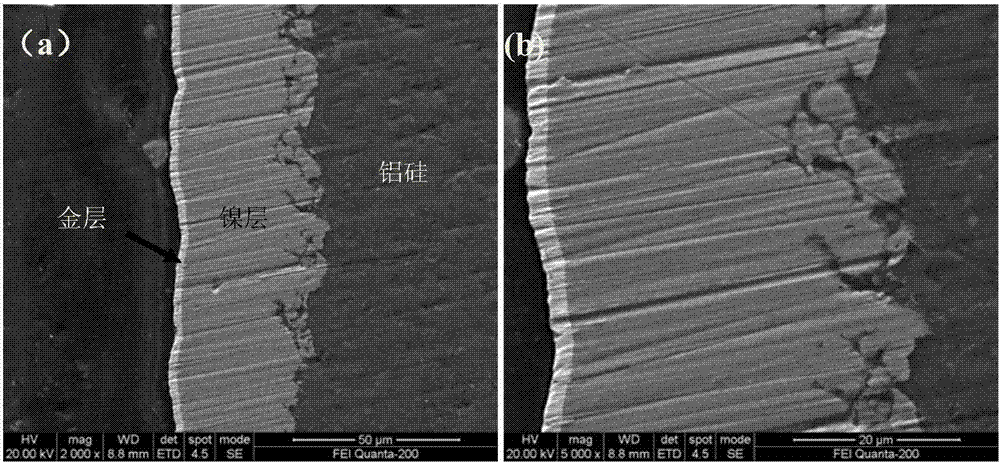

[0085] 4) Electroless nickel plating. The formula is 70g / L of nickel sulfate, 60g / L of sodium ...

Embodiment 2

[0094] High-silicon aluminum alloy plating with a silicon content of 42%.

[0095] 1) Degreasing. After machining, the high-silicon aluminum alloy with a silicon content of 42% was cleaned and degreased in an acetone solution at room temperature for 10 minutes, and dried at room temperature;

[0096] 2) coarsening. The formula is 290ml / L of nitric acid, 110ml / L of hydrofluoric acid, 100ml / L of hydrogen peroxide and water. , washed with clean water, then ultrasonically washed for 20 minutes, and dried in a 60°C drying oven;

[0097] 3) Once activated. The formula is nickel acetate 65g / L, sodium dihydrogen phosphate 85g / L and water. The mixed solution is 1L. The activation solution is heated to 160°C. During the activation process, the fluctuation does not exceed 5°C. Place the sample in the activation solution Gently shake in the middle of the oven for 12 minutes, take it out, wash it with water, and dry it in a drying oven at 60°C;

[0098]4) Electroless nickel plating. ...

Embodiment 3

[0107] Plating of high-silicon aluminum alloy with 50% silicon content.

[0108] 1) Degreasing. After machining, the high-silicon aluminum alloy with a silicon content of 50% was washed and degreased in an acetone solution at room temperature for 10 minutes, and dried in the air at room temperature; 2) coarsening. The formula is 290ml / L of nitric acid, 115ml / L of hydrofluoric acid, 100ml / L of hydrogen peroxide and water. , washed with clean water, then ultrasonically washed for 20 minutes, and dried in a 60°C drying oven;

[0109] 3) Once activated. The formula is nickel acetate 70g / L, sodium dihydrogen phosphate 90g / L and water. The mixed solution is 1L. The activation solution is heated to 160°C. During the activation process, the fluctuation does not exceed 5°C. Gently shake in the middle of the oven for 12 minutes, take it out, wash it with water, and dry it in a drying oven at 60°C;

[0110] 4) Electroless nickel plating. The formula is 80g / L of nickel sulfate, 70g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com