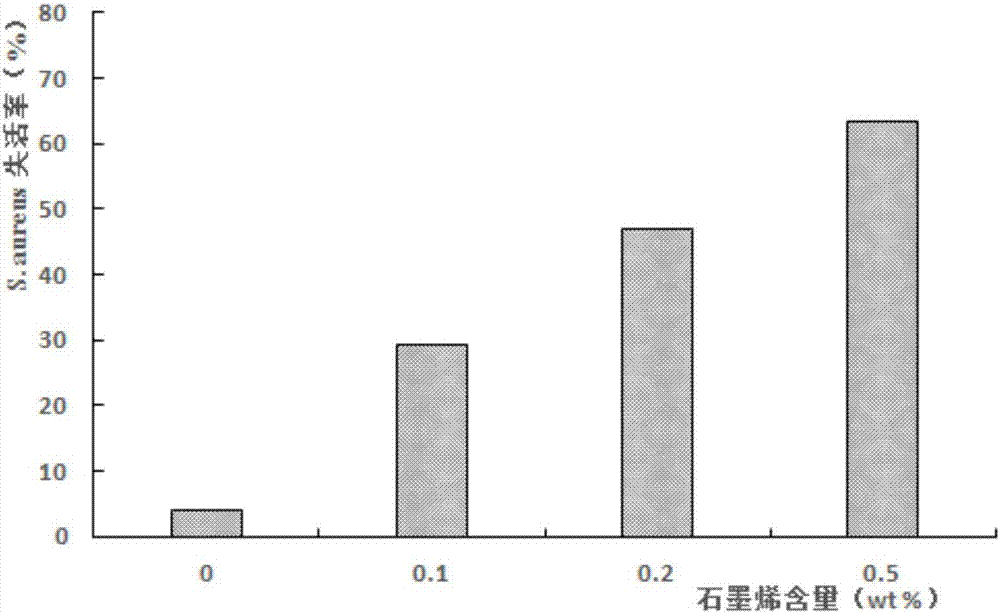

Porous silicon rubber thin film containing graphene as well as preparation method and application thereof

A rubber film and graphene technology, applied in medical science, bandages, prostheses, etc., to achieve the effects of good product safety, avoid bacterial infection, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

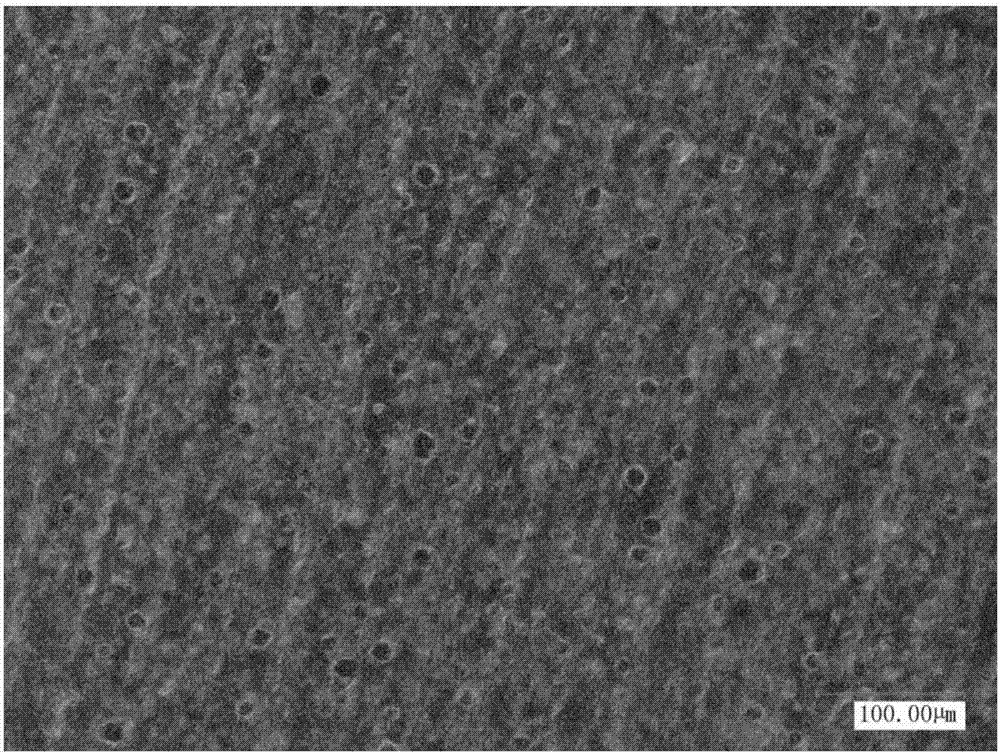

Embodiment 1

[0040] Add 4g of medical liquid high-temperature curing silicone rubber K-1008A / B resin (A:B=1:1), 3.2g of liquid paraffin and 0.04g of multilayer graphene into 8.8g of tetrahydrofuran, stir and dissolve at room temperature to obtain a uniform composition Membrane liquid, stand still or vacuum degassing for 5min. Use a film applicator to coat a film on a polytetrafluoroethylene plate, and place it naturally at 25°C for 60 minutes, and the solvent will volatilize and cause phase separation. Next, place the embryo film at 100°C to cure for 20 minutes. After the silicone rubber is cured, remove the silicone rubber film from the polytetrafluoroethylene plate, soak it in n-hexane at 65°C for 4 days, and replace the solution once a day. After 4 days, take out the silicone rubber film from n-hexane, soak in ethanol to remove n-hexane, take out the film from ethanol and place it at room temperature, and obtain a graphene-containing porous silicone rubber film after the ethanol is comp...

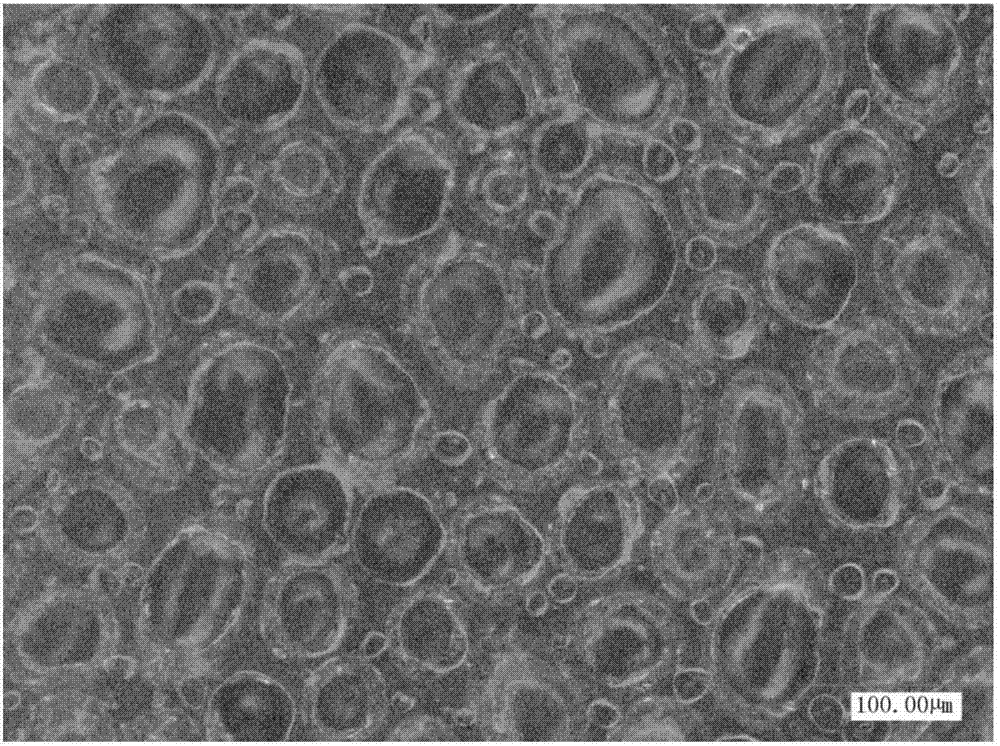

Embodiment 2

[0042] Add 4g of medical liquid high-temperature curing silicone rubber K-1008A / B resin (A:B=1:1), 3.2g of liquid paraffin and 0.04g of single-layer graphene into 8.8g of tetrahydrofuran, stir and dissolve at room temperature to obtain a uniform composition Membrane liquid, stand still or vacuum degassing for 5min. Use a film applicator to coat a film on a polytetrafluoroethylene plate, and place it naturally at 25°C for 60 minutes, and the solvent will volatilize and cause phase separation. Next, place the embryo film at 100°C to cure for 20 minutes. After the silicone rubber is cured, remove the silicone rubber film from the polytetrafluoroethylene plate, soak it in n-hexane at 65°C for 4 days, and replace the solution once a day. After 4 days, take out the silicone rubber film from n-hexane, soak in ethanol to remove n-hexane, take out the film from ethanol and place it at room temperature, and obtain a graphene-containing porous silicone rubber film after the ethanol is co...

Embodiment 3

[0044]Add 4g of medical liquid high-temperature curing silicone rubber K-1008A / B resin (A:B=1:1), 3.2g of liquid paraffin and 0.04g of graphene oxide into 8.8g of tetrahydrofuran, stir and dissolve at room temperature to obtain a uniform film solution, stand still or vacuum defoam for 5min. Use a film applicator to coat a film on a polytetrafluoroethylene plate, and place it naturally at 25°C for 60 minutes, and the solvent will volatilize and cause phase separation. Next, place the embryo film at 100°C to cure for 20 minutes. After the silicone rubber is cured, remove the silicone rubber film from the polytetrafluoroethylene plate, soak it in n-hexane at 65°C for 4 days, and replace the solution once a day. After 4 days, take out the silicone rubber film from n-hexane, soak in ethanol to remove n-hexane, take out the film from ethanol and place it at room temperature, and obtain a graphene-containing porous silicone rubber film after the ethanol is completely volatilized, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com