Preparation method of organic microporous polymer electrode material

A microporous polymer and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance, hinder the practical application of small molecule conjugated carbonyl compound electrodes, etc., and achieve good electrochemical activity, Good electrochemical performance, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of organic microporous polymer electrode material in this example, comprises the following steps:

[0030] (1) Take anhydrous aluminum chloride and sodium chloride as raw materials, carry out batching according to the mass ratio of 4.6:1 and stir at 110-200°C for 10-40min to form a molten salt phase;

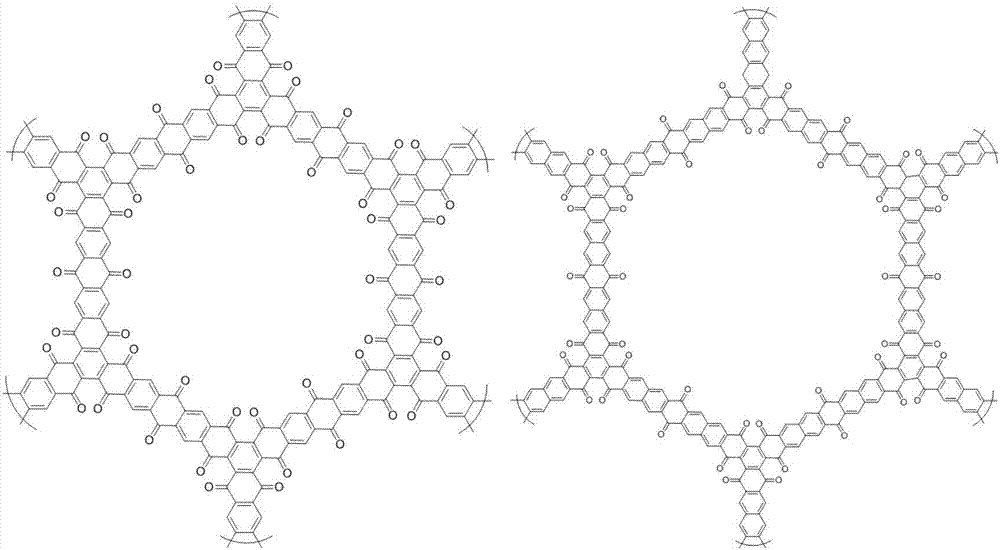

[0031] (2) Take quinones (such as anthraquinone, pentabenzoquinone, etc.) and honey stone anhydride as raw materials, and mix them uniformly at a molar ratio of 1.5:1;

[0032] (2) Add the prepared material into the molten salt phase in (1), and react at 220-280°C for 12-48 hours;

[0033] (3) Wash and purify the calcined product with different solutions to prepare the positive electrode active material of the battery, and the reflux time is 12 to 24 hours;

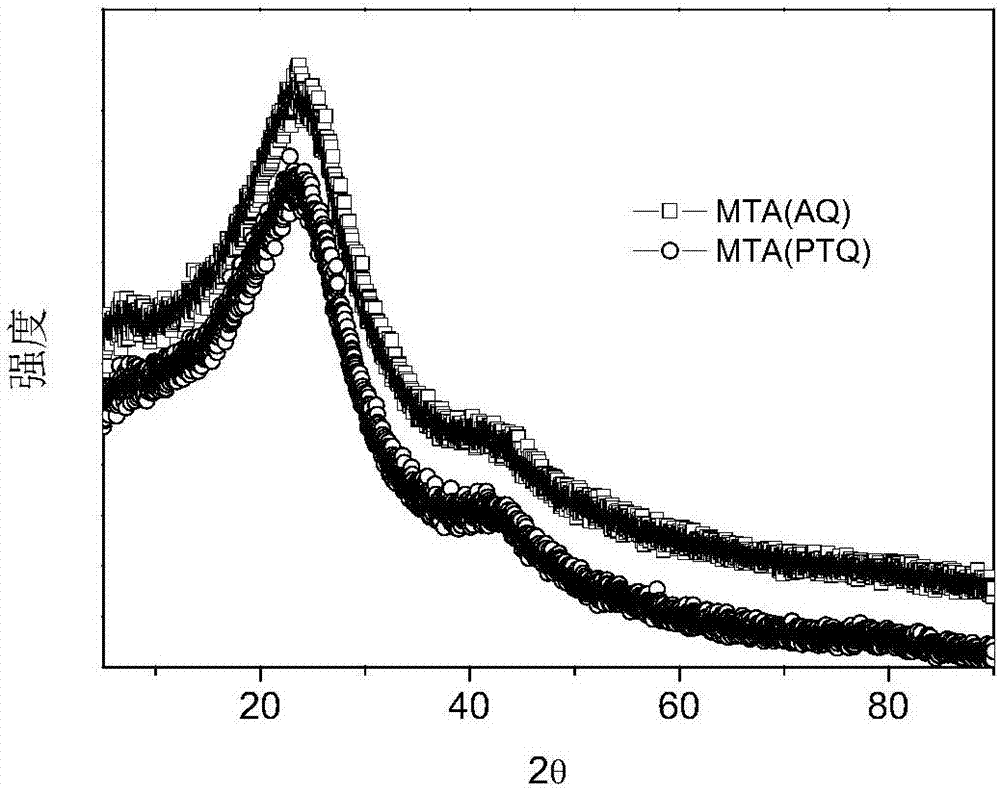

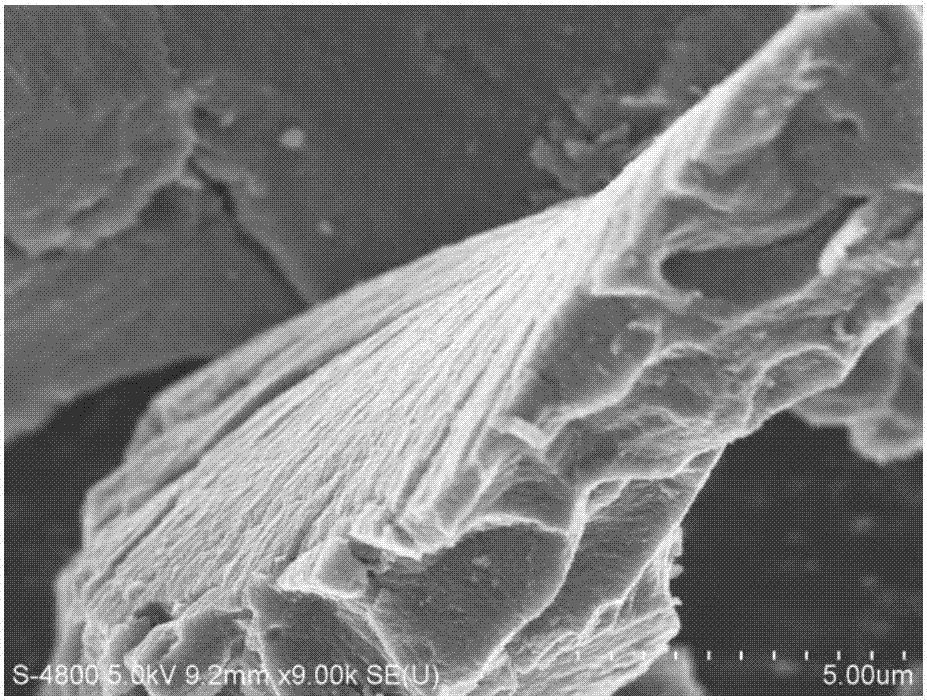

[0034] experiments and tests, such as figure 1 and figure 2 shown. Use SEM to observe the positive electrode product of sodium ion battery, such as image 3 For the SEM image of the...

Embodiment 2

[0036] A kind of preparation method of organic microporous polymer electrode material in this example, differs from above-mentioned embodiment 1 in that, in described step (2), raw material is part acenes (as anthracene, pentacene etc.) and Honey stone anhydride, all the other steps and formula are identical with embodiment 1.

[0037] The structural representation of the positive electrode product of the sodium ion battery in this example is as follows Figure 5 Shown, experiment and test condition, method are identical with embodiment 1, record current density 100mA g -1 The first charge and discharge curve is as follows Figure 6 As shown, after 80 cycles, it can have 78 (anthracene) / 115 (pentacene) mAh g -1 specific capacity.

Embodiment 3

[0039] A kind of preparation method of organic microporous polymer electrode material in this example, differs from above-mentioned embodiment 1 in that, in described step (2), raw material is part azine class (as phenazine etc.) and honey stone anhydride, All the other steps and formula are the same as in Example 1.

[0040] The structural representation of the positive electrode product of the sodium ion battery in this example is as follows Figure 7 Shown, experiment and test condition, method are identical with embodiment 1, record current density 100mA g -1 The first charge and discharge curve is as follows Figure 8 As shown, after 50 cycles, it can have 212mAh g -1 specific capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com