Porous biological piezoelectric ceramic and preparation method thereof

A bio-piezoelectric ceramic and ceramic powder technology, which is applied to ceramic products, other household appliances, applications, etc., can solve the problems of irritating taste, discomfort to the human body, and discomfort in medical materials, and achieve uniform pore structure and foaming effect. Excellent and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

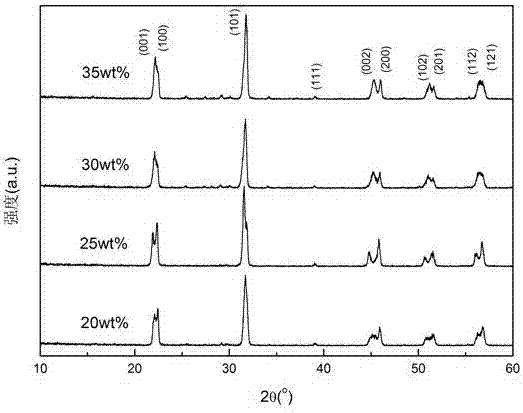

[0031] The preparation method of porous LNK biological piezoelectric ceramics of the present invention is carried out according to the following processes:

[0032] Step 1, pre-burning LNK powder: with niobium pentoxide (Nb 2 o 5 ), potassium carbonate (K 2 CO 3 ), sodium carbonate (Na 2 CO 3 ), lithium carbonate (Li 2 CO 3 ) as raw material, according to chemical formula (Li 0.06 Na 0.5 K 0.44 )NbO 3 After batching, ball mill and pre-burn the powder after taking it out. The pre-firing system is to raise the temperature to 250°C at 3°C / min and keep it for 30 minutes; then raise the temperature to 600°C at 3°C / min and keep it for 120 minutes; then raise the temperature to 890°C at 3°C / min and keep it for 2 hours; get LNK ceramics powder.

[0033] Step 2, prepare LNK ceramic slurry: Pour the pre-fired LNK ceramic powder and deionized water into the ball mill tank, and add ZrO at a ball weight ratio of 1:2 2Small balls, ball milled for 12 hours to obtain the LNK slur...

Embodiment 1

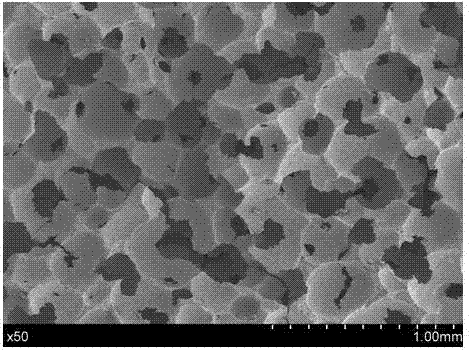

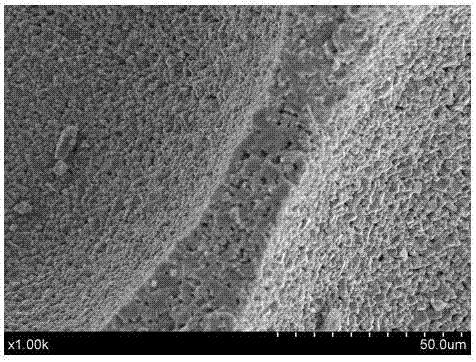

[0046] niobium pentoxide (Nb 2 o 5 ), potassium carbonate (K 2 CO 3 ), sodium carbonate (Na 2 CO 3 ), lithium carbonate (Li 2 CO 3 ) as raw material, according to chemical formula (Li 0.06 Na 0.5 K 0.44 )NbO 3 Ingredients, pre-fired LNK powder at 890°C. Egg white is extracted from eggs, after removing impurities in the egg white, it is magnetically stirred for 2 hours, and the upper layer of foam is removed to obtain a pure egg white liquid for later use. Prepare LNK ceramic slurry according to the mass ratio of LNK powder and deionized water at 1:0.5, and put it into a ball mill jar for ball milling for 12 hours. Add 20% by mass of egg white as a foaming agent to the ball-milled LNK slurry, and stir magnetically for 2 hours to fully foam. Pour the fully foamed slurry into a self-made mold, put it into a water bath and heat it at 80°C to facilitate the curing of the slurry. The cured slurry was allowed to stand at room temperature for 24 hours, then put into an ov...

Embodiment 2

[0048] niobium pentoxide (Nb 2 o 5 ), potassium carbonate (K 2 CO 3 ), sodium carbonate (Na 2 CO 3 ), lithium carbonate (Li 2 CO 3 ) as raw material, according to chemical formula (Li 0.06 Na 0.5 K 0.44 )NbO 3 Ingredients, pre-fired LNK powder at 890°C. Egg white is extracted from eggs, after removing impurities in the egg white, it is magnetically stirred for 2 hours, and the upper layer of foam is removed to obtain a pure egg white liquid for later use. Prepare LNK ceramic slurry according to the mass ratio of LNK powder and deionized water of 1:0.67, and put it into a ball mill jar for ball milling for 12 hours. Add 30% by mass of egg white as a foaming agent to the ball-milled LNK slurry, and stir magnetically for 2 hours to fully foam. Pour the fully foamed slurry into a self-made mold, put it into a water bath and heat it at 80°C to facilitate the curing of the slurry. The cured slurry was left to stand at room temperature for 24 hours, then put into an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com