A high-content natural shikimic acid extract product and a preparing method thereof

A technology of shikimic acid and extract, applied in the field of separation and preparation of shikimic acid extract, can solve problems such as environmental pollution, producer, environmental impact, and film blockage, and achieves alleviation of plant resource shortage problems, low requirements for instruments and equipment, and low operation requirements. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Content detection of shikimic acid in ginkgo biloba and production wastewater

[0029] The method for determining the content of shikimic acid in Ginkgo biloba and macroporous resin washing liquid is as follows:

[0030] Instrument: Agilent HPLC 1260

[0031] Stationary phase: Agilent XDB-C8 column 250mm×4.6mm, 5μm

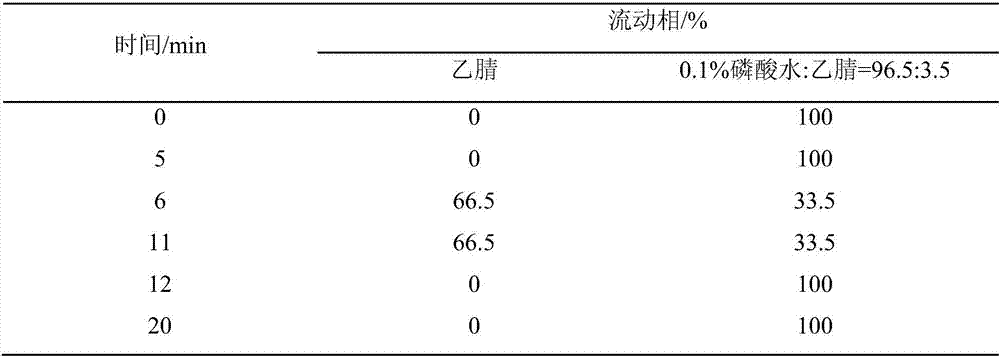

[0032] Table 1 mobile phase and gradient list

[0033]

[0034] Flow rate: 1.0ml / min; detection wavelength: 215nm; injection volume: 10μL.

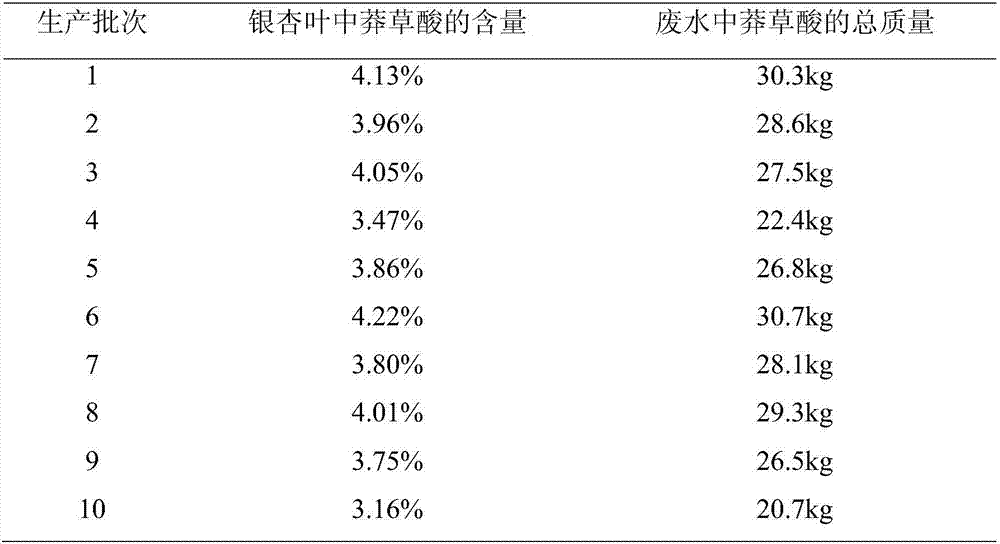

[0035] The results are shown in Table 2. The content of shikimic acid in Ginkgo biloba is basically 3-5%, and most of the shikimic acid is finally lost through the macroporous resin step.

[0036] Table 2 Shikimic acid detection results

[0037]

[0038] Note: The feeding amount of ginkgo biloba for each batch is 1 ton.

Embodiment 2

[0039] Embodiment 2: the selection of purification resin

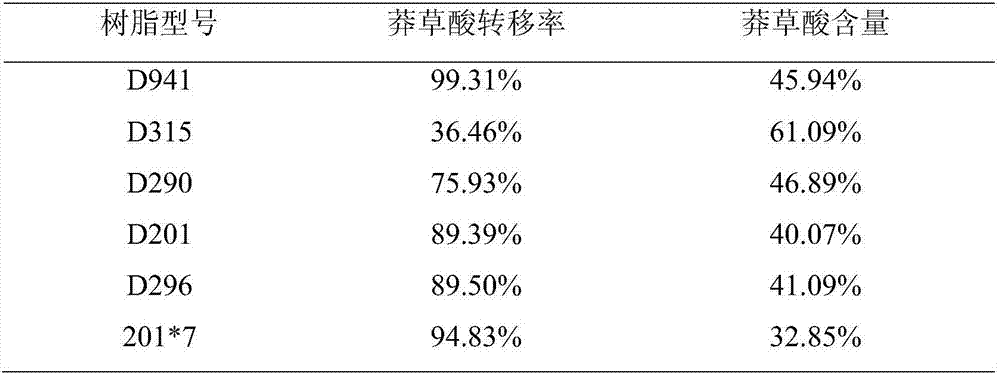

[0040] Take ginkgo biloba extract production waste water, use D941, D315, D290, D201, D296, 201*7 type anion exchange resin to absorb and separate, first wash with water, and then use aqueous solution containing 1mol / L NaOH to obtain the eluate After concentration and drying, the transfer rate of shikimic acid and the content of shikimic acid in the extract were determined.

[0041]The results are shown in Table 3. D941 anion exchange resin has the highest transfer rate of shikimic acid. Although D315 anion exchange resin has the highest content of shikimic acid in the purified extract, the transfer rate is less than 40%. Therefore, D941 anion exchange resin was selected for adsorption separation.

[0042] Table 3 Anion exchange resin type screening

[0043]

Embodiment 3

[0044] Example 3: Screening of Elution and Impurity Removal Solvents

[0045] Take ginkgo biloba extract production wastewater, use D941 anion exchange resin to absorb and separate, wash with water, and then sequentially elute with aqueous solution containing 0.01, 0.1 and 1mol / L HCl, collect each eluted part, concentrate and dry, and measure the transfer of shikimic acid rate and content; or wash with water first, and then sequentially elute with an aqueous solution containing 0.005, 0.025, 0.05, 0.1, 0.5, 1mol / L NaOH, collect each eluted part, concentrate and dry, and measure the transfer rate and content of shikimic acid.

[0046] The results are shown in Table 4. After being eluted with an aqueous solution containing HCl, the color of the concentrated solution gradually deepened during the concentration process, and finally turned black. It may be that under strong acidic conditions, both sugar and shikimic acid were dehydrated and carbonized, making the content of shikimic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com