Dihydroxyl polyphenyl ether and preparation method thereof

A technology of bishydroxy polyphenylene ether and toluene, which is applied in the field of bishydroxy polyphenylene ether and its preparation, can solve the problems of reducing the market competitiveness of products, long process cycle, difficult separation, etc., and can meet the requirements of industrial production and have uniform molecular weight distribution. , The effect of molecular weight control and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

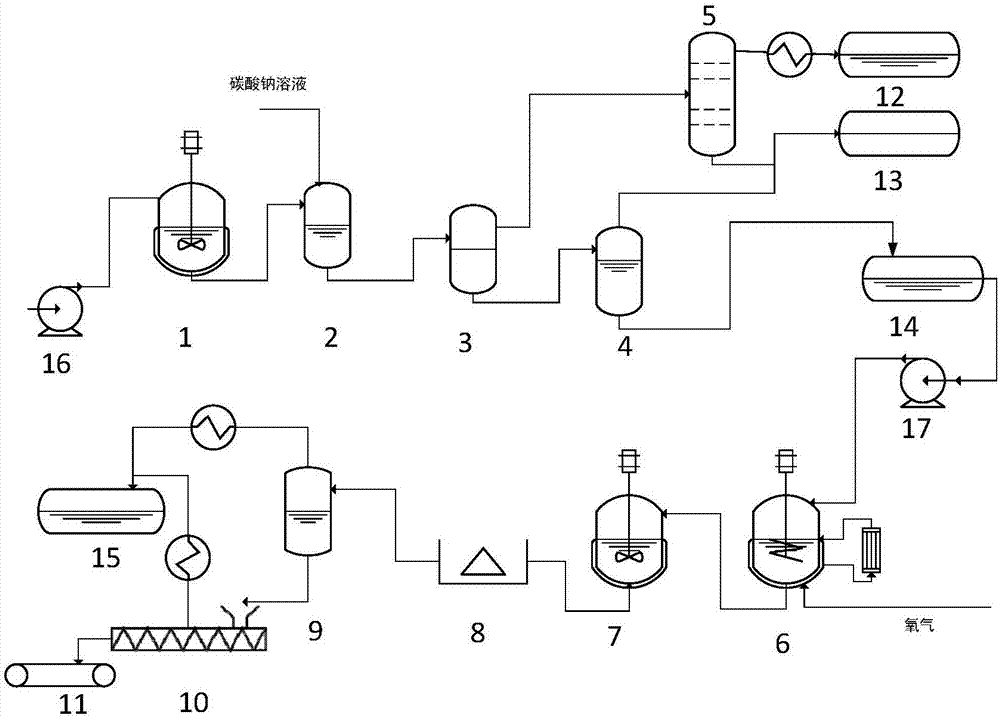

[0063] The preparation method of the bishydroxy polyphenylene ether of the present invention comprises passing through a reaction liquid composed of a solvent, a metal salt and an amine compound to oxidatively couple monomer products with an oxygen-containing gas, and then terminating the reaction to obtain bishydroxy polyphenylene ether; the bishydroxy polyphenylene ether of the present invention The preparation method of the hydroxypolyphenylene ether has simple process operation, low production cost and high production efficiency, and can meet the industrial production requirements of the low-molecular-weight dihydroxypolyphenylene ether.

[0064] In a preferred embodiment of the present invention, the monophenol is selected from one or more of phenol and alkylphenol, preferably selected from 2,6-xylenol, 2,3-xylenol, 2 , one of 5-xylenol, 3,5-xylenol phenol, o-cresol, m-cresol, 2,3,6-trimethylphenol, 2,3,5-trimethylphenol and phenol One or more, more preferably 2,6-xylenol...

Embodiment 1

[0109] A preparation method of bishydroxy polyphenylene ether, comprising the steps of:

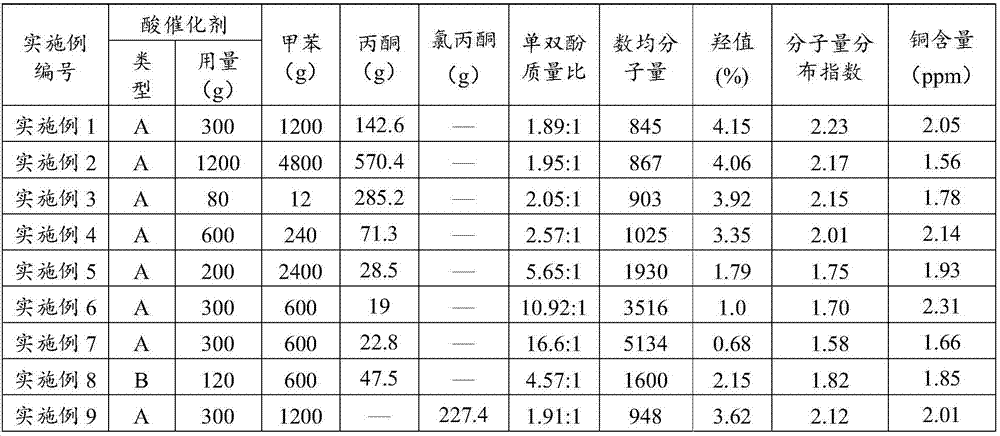

[0110] 1. Monomer preparation: put 1200g 2,6-xylenol, 1200g toluene and 300g sulfonated polystyrene-divinylbenzenesulfonic acid resin into 5000mL monomer reactor 1, start stirring and heat up to 70°C 142.6g of acetone is added to the reaction kettle 1 with the raw material metering pump 16, and the addition time is 80min. After the acetone is added, the timing starts. After 480min, the reaction solution is filtered and moved to the neutralization kettle 2, and 100g of the acetone is added to the neutralization kettle 2. The sodium carbonate solution with a mass fraction of 20% is stirred for 10 min and then moved into the phase separation tank 3. After the phase separation, the light phase enters the distillation tower 5 for distillation. The tank 13 is used for further processing; the heavy phase in the phase separation tank 3 enters the dehydration tower 4 for dehydration and then enter...

Embodiment 2

[0113] The low molecular weight dihydroxy polyphenylene ether was prepared according to the method of Example 1, except that the amount of toluene used in the monomer preparation was 4800g, the amount of acid catalyst was 1200g, the amount of acetone was 570.4g, and the monomer reaction temperature was 20°C. The reaction time is 24 hours, the reaction temperature of the polymerization reaction is 90°C, and the reaction time of the polymerization reaction is 1h. After the reaction is terminated, the temperature is controlled to 90°C, and the stirring is continued for 30 minutes. The precipitation temperature is 100°C, and the extrusion temperature is 200°C. The experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com