Celery fermented solution, celery fermented beverage and preparation methods thereof

A technology of fermented beverages and fermented liquid, applied to bacteria used in food preparation, oligosaccharide-containing food ingredients, protein-containing food ingredients, etc., can solve the problems of low celery content and discount of celery diet and health effects, and achieve maintenance Antioxidant ability, reducing the production of intestinal toxins, weakening the effect of medicinal taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

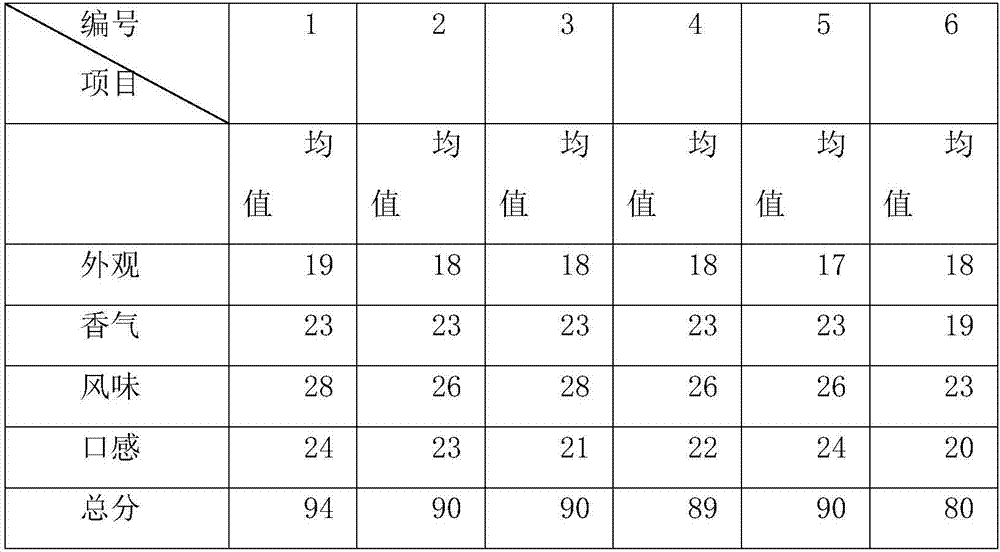

Examples

Embodiment 1

[0043] A preparation method for celery fermented drink, comprising the steps of:

[0044] Mix erythritol 12kg, sucralose 0.03kg, stevioside 0.02kg, corn oligopeptide powder 1kg, xylooligosaccharide 1.3kg, L-arabinose 1.2kg, maltitol 25kg, xylitol 3kg evenly, Then mix with 60 kilograms of celery fermentation broth, filter through a 50-mesh duplex pipeline filter, homogenize under a pressure of 20 MPa for 15 seconds, treat at 120°C for 20 seconds for high-temperature instantaneous sterilization, and cool the sterilized fermentation broth to obtain Celery fermented beverage;

[0045] The celery fermented beverage is light green, delicate in taste, sweet and sour, soft and suitable, can be stored at normal temperature, and has better flavor when refrigerated.

[0046] The preparation method of described celery fermented liquid comprises the steps:

[0047] Raw material processing: After cleaning the fresh celery, according to the mass ratio of 7.5 parts of celery and 3 parts of ...

Embodiment 2

[0053] A preparation method for celery fermented drink, comprising the steps of:

[0054] Mix 10kg of erythritol, 0.01kg of sucralose, 0.01kg of stevia, 0.5kg of corn oligopeptide powder, 0.8kg of xylooligosaccharide, 0.5kg of L-arabinose, 20kg of maltitol, and 1kg of xylitol , then mix with celery fermented liquid 45kg, stir evenly, obtain the crude product of celery juice;

[0055] Filter the crude celery juice with a 50-mesh sieve, homogenize the filtrate under a pressure of 18-20Mpa for 15s, and then perform high-temperature instant sterilization at 110°C for 20 seconds, with an outlet temperature of 30°C, and pour the drink into the bottle. Invert the bottle for 5 minutes, and finally obtain cooling by spray cooling to obtain celery fermented beverage.

[0056] The celery fermented beverage prepared in this example is light green, delicate in taste, sweet and sour, soft and suitable, can be stored at room temperature, and has a better flavor when refrigerated.

[0057] ...

Embodiment 3

[0063] A preparation method for celery fermented drink, comprising the steps of:

[0064] Mix erythritol 15kg, sucralose 0.05kg, stevioside 0.04kg, corn oligopeptide powder 2kg, xylooligosaccharide 2kg, L-arabinose 2kg, maltitol 30kg, xylitol 5kg, and then mix with 60kg celery fermented liquid mixes, stirs evenly, obtains the crude product of celery juice;

[0065] Filter the crude celery through a 50-mesh sieve, homogenize the filtrate under a pressure of 20 MPa for 15 seconds, sterilize it at a temperature of 110° C. for 10 seconds, and cool to obtain a celery fermented beverage;

[0066] The celery fermented beverage is light green, delicate in taste, sweet and sour, soft and suitable, can be stored at normal temperature, and has better flavor when refrigerated.

[0067] The preparation method of described celery fermented liquid, comprises the following steps:

[0068] According to the mass ratio of celery raw materials: 8 parts of celery, 2 parts of water, add water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com