MoS2/GNRs composite material with loose three-dimensional winding structure, preparation method and application thereof

A technology of graphene nanobelts and composite materials, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as limited specific surface area, poor rate performance, and large capacity loss. Achieve the effect of good dispersion, high conductivity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

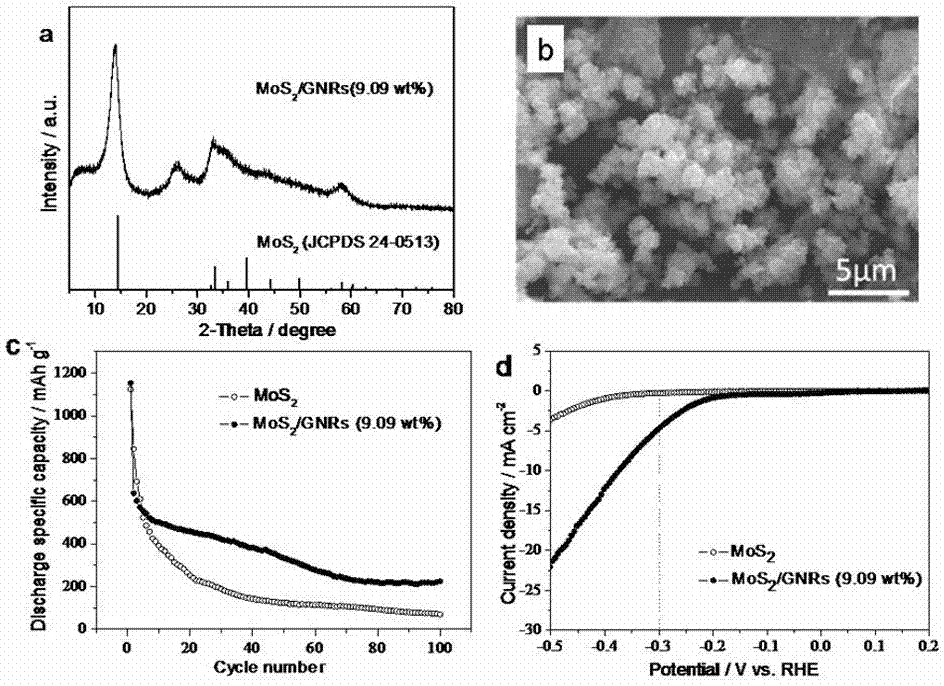

[0024] Take 3.531 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2.521 g H 2 C 2 o 4 2H 2 O powder is placed in the agate grinder and mixed thoroughly and ground. Add 10.8 mL of deionized water to a 20 mL polytetrafluoroethylene autoclave, then add 3.045 g of CS(NH 2 ) 2 , stir well until the powder dissolves. Joined by (NH 4 ) 6 Mo 7 o 24 4H 2 O and H 2 C 2 o 4 2H 2 O Mix the ground mixture and stir well. then press Add graphene nanoribbons at a mass ratio of 100:10 (the mass fraction of graphene nanoribbons is 9.09wt%). After the mixture was hydrothermally reacted for 5 hours, it was centrifuged, deionized water and absolute ethanol were ultrasonically oscillated, and the product was washed 3 times, dried in vacuum at 70 °C, and annealed at 500 °C for 2 hours in a nitrogen atmosphere to obtain MoS 2 / GNRs (9.09 wt%) composite. The heating and cooling rates of composite materials annealed in nitrogen atmosphere are both 2 ℃·min -1 .

[0025] The crystalline phase of ...

Embodiment example 2

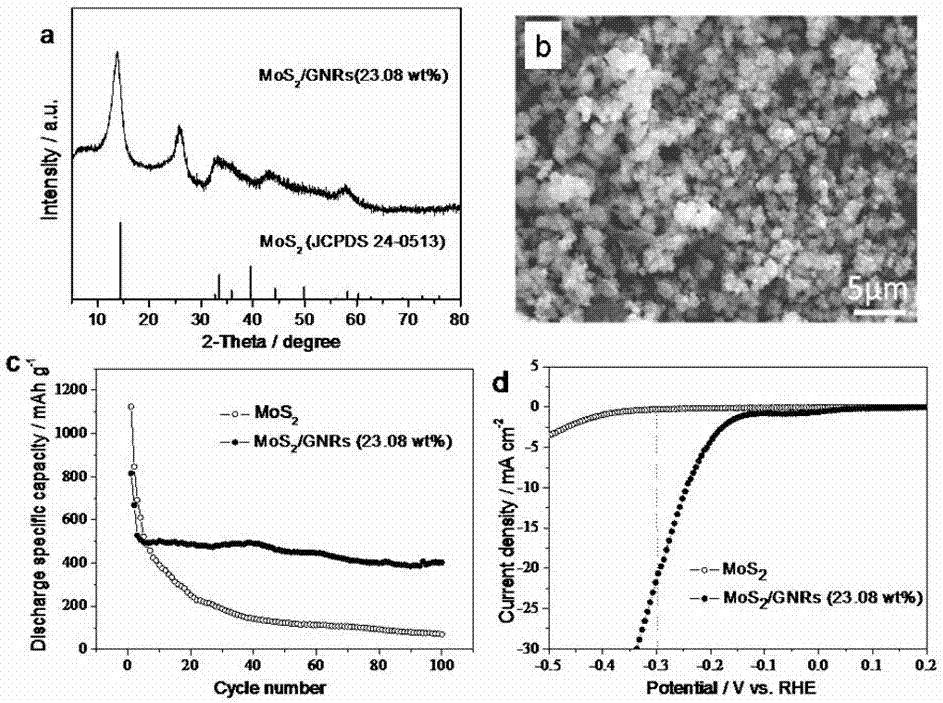

[0027] Take 3.531 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2.521 g H 2 C 2 o 4 2H 2 O powder is placed in the agate grinder and mixed thoroughly and ground. Add 10.8 mL of deionized water to a 20 mL polytetrafluoroethylene autoclave, then add 3.045 g of CS(NH 2 ) 2 , stir well until the powder dissolves. Joined by (NH 4 ) 6 Mo 7 o 24 4H 2 O and H 2 C 2 o 4 2H 2 O the ground mixture, stir well. then press GNRs were added at a mass ratio of 100:30 (the mass fraction of graphene nanoribbons was 23.08 wt%). After the mixture was hydrothermally reacted for 5 hours, it was centrifuged, deionized water and absolute ethanol were ultrasonically oscillated, and the product was washed 3 times, dried in vacuum at 70 °C, and annealed at 500 °C for 2 hours in a nitrogen atmosphere to obtain MoS 2 / GNRs((23.08wt%) composite material. During the annealing process of the composite material, the heating and cooling rates were 2 ℃·min -1 .

[0028] Adopt X-ray powder diffraction te...

Embodiment example 3

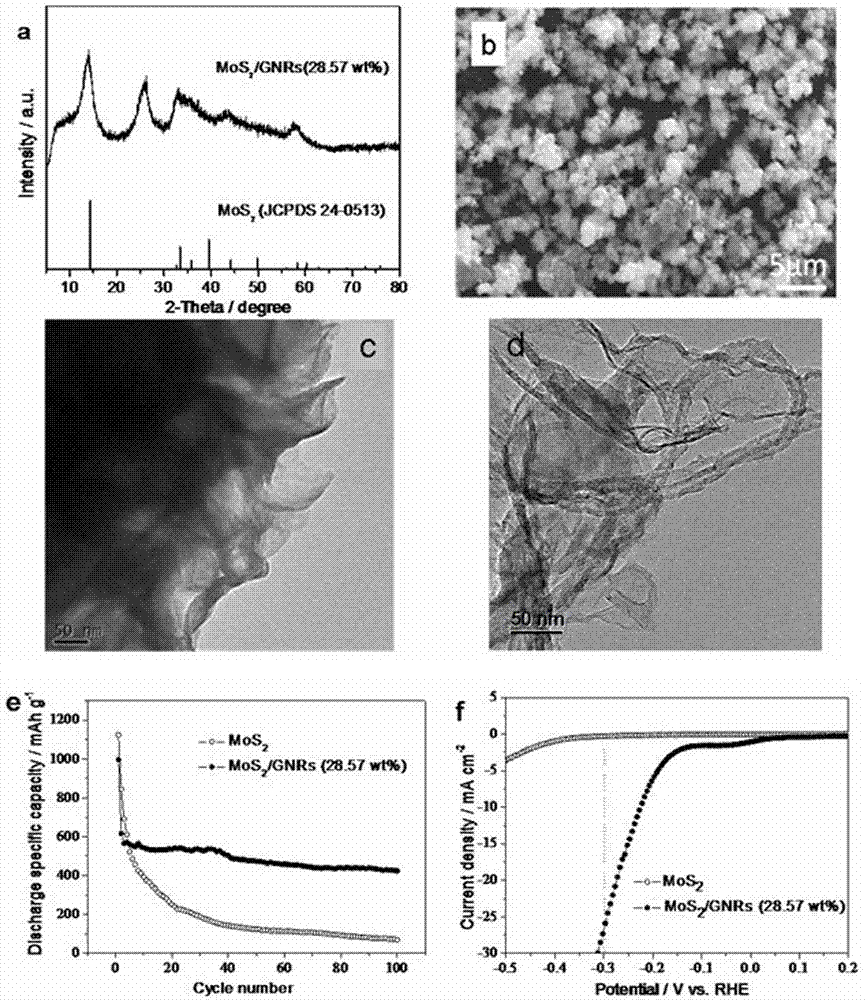

[0030] Take 3.531 g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2.521 g H 2 C 2 o 4 2H 2 O powder, mix well and grind. Add 10.8 mL of deionized water to a 20 mL polytetrafluoroethylene autoclave, and then add 3.045 g of CS(NH 2 ) 2 , stir well until the powder dissolves. Joined by (NH 4 ) 6 Mo 7 o 24 4H 2 O and H 2 C 2 o 4 2H 2 O the ground mixture, stir well. then press GNRs were added at a mass ratio of 100:40 (the mass fraction of graphene nanoribbons was 28.57 wt%). After the mixture was hydrothermally reacted for 5 hours, it was centrifuged, washed, dried in vacuum at 70 °C, and annealed at 500 °C for 2 hours in a nitrogen atmosphere to obtain MoS 2 / GNRs((28.57 wt%) composite material. The heating and cooling rate of the composite material annealed in nitrogen atmosphere is 2 ℃·min -1 .

[0031] Adopt X-ray powder diffraction test to analyze the crystalline phase of prepared product, the result is as follows image 3 Shown in a. Compared with the standard spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com