Anti-seismic heat-insulating high-strength mortar

A mortar and high-strength technology, applied in the field of high-strength mortar for earthquake resistance and heat insulation, can solve the problems of energy consumption of cold and hot air, poor waterproof and moisture-proof performance, poor thermal insulation ability, etc. good effect of cracking and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

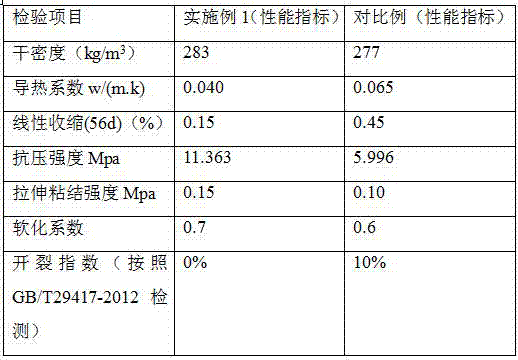

Examples

Embodiment 1

[0021] An anti-seismic and heat-insulating high-strength mortar, the raw materials are composed of the following parts by weight: 40 parts of ferronickel slag, 38 parts of ordinary Portland cement, 5 parts of gypsum, 6 parts of aluminum silicate powder, 10 parts of coconut palm silk, high 12 parts of silica quartz sand, 18 parts of composite filler, 6 parts of potassium pyrophosphate, 3 parts of sodium lauryl sulfate, 6 parts of cocamidopropyl betaine, 7 parts of blue tungsten powder, appropriate amount of water.

[0022] The composite filler is made from the following raw materials in parts by weight: 15 parts of diatomite, 20 parts of silane coupling agent KH550, 8 parts of calcium lignosulfonate, 7 parts of coconut oil fatty acid diethanolamide, 6 parts of glass fiber, and auxiliary agent BYK108 4 parts.

[0023] The preparation method of the composite filler comprises the following steps: mixing diatomaceous earth, silane coupling agent KH550, calcium lignosulfonate, cocon...

Embodiment 2

[0030] An anti-seismic and heat-insulating high-strength mortar, the raw materials are composed of the following parts by weight: 55 parts of ferronickel slag, 42 parts of ordinary Portland cement, 7 parts of gypsum, 6 parts of expanded perlite powder, 12 parts of coconut palm silk, high 12 parts of silica quartz sand, 18 parts of composite filler, 6 parts of potassium pyrophosphate, 3 parts of sodium lauryl sulfate, 6 parts of cocamidopropyl betaine, 5 parts of blue tungsten powder, appropriate amount of water.

[0031] The composite filler is prepared from the following raw materials in parts by weight: 15 parts of diatomite, 20 parts of silane coupling agent KH550, 8 parts of calcium lignosulfonate, 6 parts of coconut oil fatty acid diethanolamide, 10 parts of glass fiber, and auxiliary agent BYK1084 share.

[0032] The preparation method of the composite filler comprises the following steps: mixing diatomaceous earth, silane coupling agent KH550, calcium lignosulfonate, co...

Embodiment 3

[0035] An anti-seismic and heat-insulating high-strength mortar, the raw materials are composed of the following parts by weight: 60 parts of ferronickel slag, 50 parts of ordinary Portland cement, 8 parts of gypsum, 9 parts of calcium silicate powder, 15 parts of coconut palm silk, high 15 parts of silica quartz sand, 20 parts of composite filler, 8 parts of potassium pyrophosphate, 5 parts of sodium lauryl sulfate, 8 parts of cocamidopropyl betaine, 8 parts of blue tungsten powder, appropriate amount of water.

[0036] The composite filler is prepared from the following raw materials in parts by weight: 15 parts of diatomite, 22 parts of silane coupling agent KH550, 10 parts of calcium lignosulfonate, 7 parts of coconut oil fatty acid diethanolamide, 10 parts of glass fiber, and auxiliary agent BYK108 4 parts.

[0037] The preparation method of the composite filler comprises the following steps: mixing diatomaceous earth, silane coupling agent KH550, calcium lignosulfonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com