Tea polyphenol microcapsules with fixed-point release characteristics and application thereof

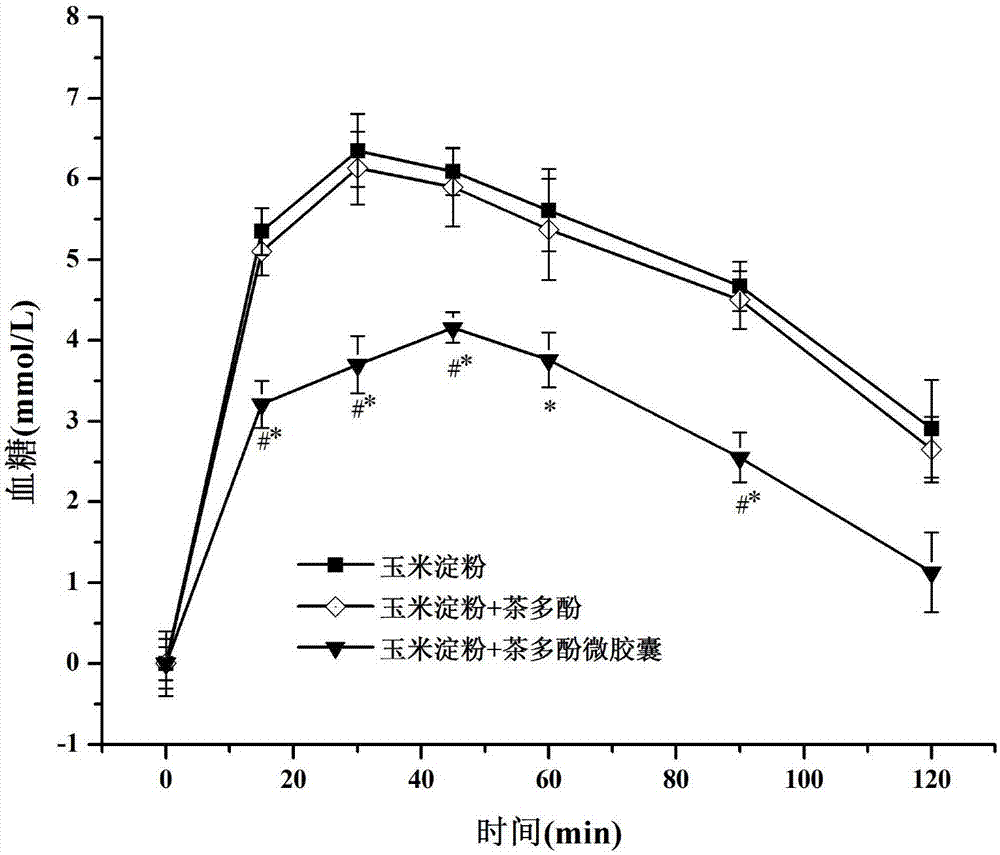

A technology for tea polyphenols and microcapsules, applied in the field of tea polyphenol microcapsules, can solve the problems of inability to effectively prevent damage, rapid loss of tea polyphenols, poor physiological compatibility, etc., and achieves perfect capsule shape, stable blood sugar, and easy access to materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

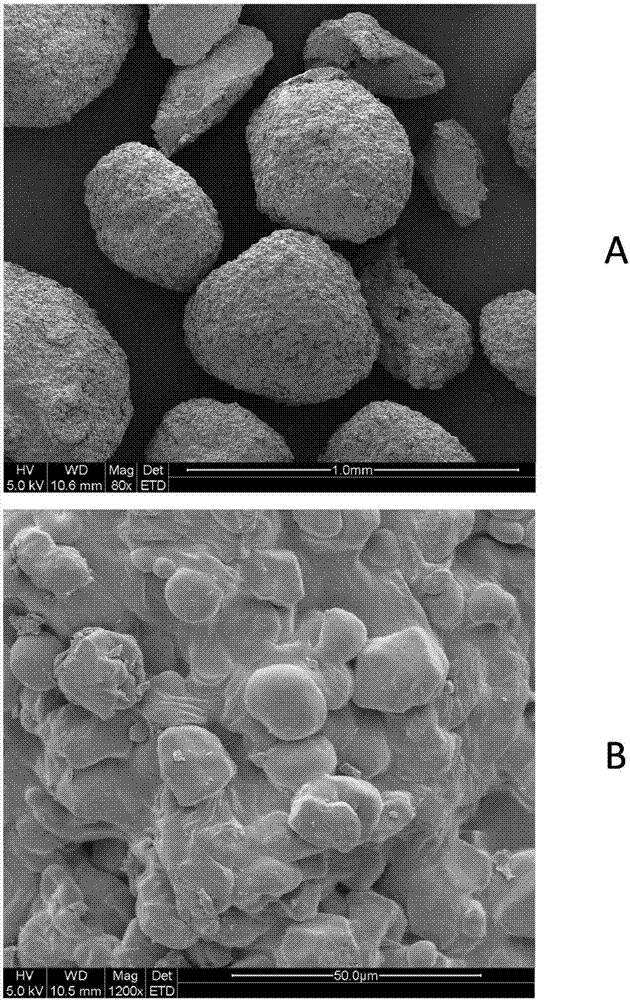

[0045] Preparation of modified starch: The modified starch prepared in this example is porous corn starch.

[0046] Accurately weigh 15g of raw corn starch on a dry basis, place it in a 250°C Erlenmeyer flask, add a certain amount of sodium acetate buffer to adjust the pH to 4.8, and configure it into a starch milk solution with a concentration of 20% (i.e. 200g / L). Preheat in a water bath for 15 minutes. Accurately weigh the α-amylase and glucoamylase of 2.8% (the quality of enzyme accounts for the percentage of starch dry basis mass), (1:2), wherein the enzyme activity of α-amylase is 1500U / g, and the enzyme activity of glucoamylase is 10 10,000 U / g, the enzyme dosage ratio of α-amylase and glucoamylase is 1:2, use acetate buffer to make enzyme solution, transfer all the enzyme solution to starch suspension and time it accurately, and react in a constant temperature oscillator After 16 hours, 5ml of 40g / L sodium hydroxide solution was added to terminate the reaction. Centr...

Embodiment 2

[0049] Sodium alginate and chitosan were used as wall materials, and the effect of the concentration of chitosan solution on the embedding rate should be considered when the modified starch was used for secondary embedding after absorbing tea polyphenols.

[0050] Add 1.5g of modified starch and 20ml of tea polyphenol solution with a concentration of 25mg / ml to the beaker, place it in a constant temperature water bath shaker at 20°C, and absorb at 110r / min for 60min. Take out the beaker, add 10ml of sodium alginate solution with a mass concentration of 0.05% (ie 0.5g / L) therein, after mixing evenly, add 25mL of a calcium chloride solution with a concentration of 1.2% (ie 12g / L) and use the volume fraction In the mixed solution of chitosan solution 25ml of different mass concentrations (0.01%, 0.05%, 0.10%, 0.20%, 0.30%) prepared by 8% glacial acetic acid, adjust the pH of the mixed solution to be 3. The impact is shown in Table 1.

[0051] Table 1 The effect of mass concentra...

Embodiment 3

[0055] Weigh 1.5g of the modified starch prepared in Example 1, and 25ml of the TP solution with a concentration of 25mg / ml was shaken and adsorbed for 60min, then mixed evenly with 10ml of 0.15% (w / v) sodium alginate solution, and pumped into 25ml of 0.1% (w / v) chitosan solution and 1.2% (w / v) CaCl 2 25ml of the mixed solution, reacted for 10min, collected by filtration and washed three times with distilled water, then put the tea polyphenol carrying system in a vacuum oven at 40°C for drying to obtain the tea polyphenol carrying system. The tea polyphenols loading capacity of the carrier system was determined to be 167.4 mg / g by the Folin's phenol method.

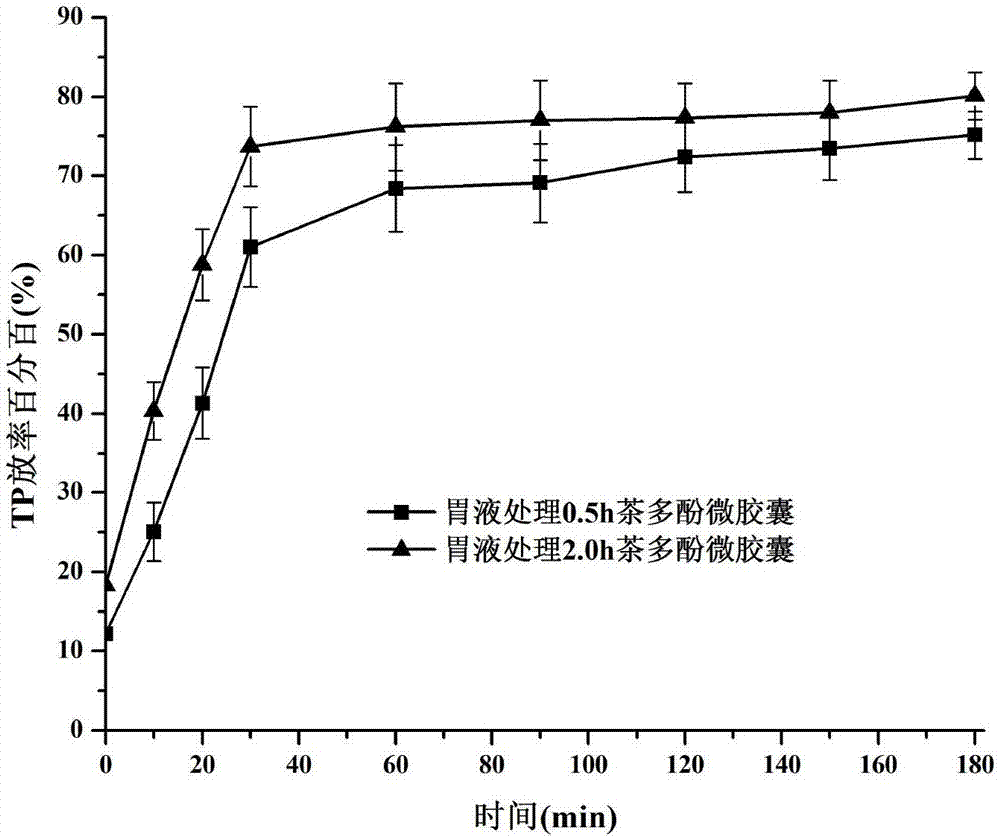

[0056] The tea polyphenol delivery system of this example was used to measure the release rate of tea polyphenols in simulated intestinal juice after being treated in simulated gastric juice for 0.5 h and 2.0 h by the Folin method.

[0057] Tea polyphenol release rate = tea polyphenol content in intestinal juice / tea po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com