Preparation method of coating type nickel-doped ferrous sulfide/carbon composite electrode

A carbon composite material and iron sulfide technology, which is applied in the field of electrochemistry and can solve the problems such as nickel-doped iron sulfide/carbon composite material electrodes that have not yet been found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

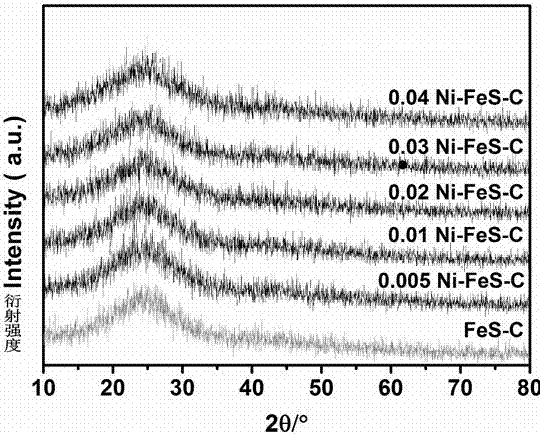

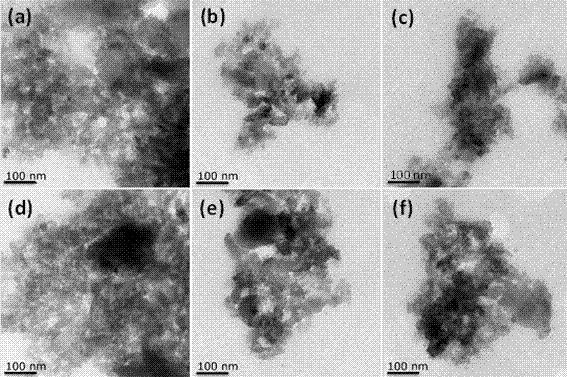

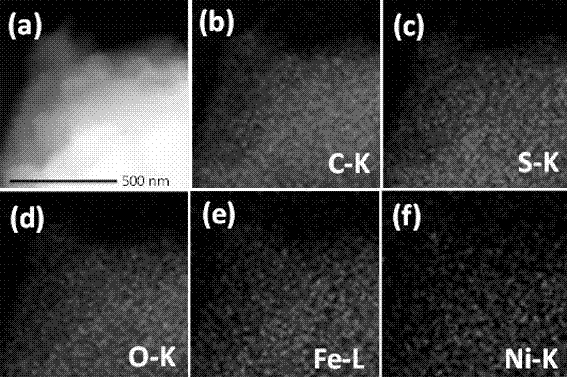

Embodiment 1

[0037] The preparation of FeS-C / CC electrode adopts the method of coating-vulcanization: Weigh 1 g of tannic acid in a 50 mL beaker, add 10 mL of deionized water to it, and magnetically stir until it is completely dissolved to form solution A; Weigh 0.2 g of ferric nitrate nonahydrate and dissolve it in 15 mL of deionized water to form solution B; slowly add the obtained clear solution B to solution A, and stir magnetically at room temperature for 2 h to form colloidal solution C. Take a size of about 1×2 cm 2 The carbon cloth (CC) was soaked in colloidal solution C for about 1 h, taken out, put into an oven, and dried at 60 °C for 6 h. Weigh 0.1 g of sulfur powder and transfer it into a semi-closed porcelain boat, then transfer the impregnated carbon cloth (CC) into the porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of Ar gas, the The temperature-programmed tube furnace was heated to 400 °C at a heating rate of 10 °C / min a...

Embodiment 2

[0039] The preparation of FeS-C / CC electrode adopts the method of coating-vulcanization: Weigh 1 g of tannic acid in a 50 mL beaker, add 10 mL of deionized water to it, and magnetically stir until it is completely dissolved to form solution A; Weigh 0.2 g of ferric nitrate nonahydrate and dissolve it in 15 mL of deionized water to form solution B; slowly add the obtained clear solution B to solution A, and stir magnetically at room temperature for 2 h to form colloidal solution C. Take a size of about 1×2 cm 2 The carbon cloth (CC) was soaked in colloidal solution C for about 1 h, taken out, put into an oven, and dried at 60 °C for 6 h. Weigh 0.1 g of sulfur powder and transfer it into a semi-closed porcelain boat, then transfer the impregnated carbon cloth (CC) into the porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of Ar gas, the The temperature-programmed tube furnace was heated to 400 °C at a heating rate of 10 °C / min a...

Embodiment 3

[0042] The preparation of FeS-C / CC electrode adopts the method of coating-vulcanization: Weigh 2 g of tannic acid into a 50 mL beaker, add 10 mL of deionized water to it, and magnetically stir until it is completely dissolved to form solution A; Weigh 0.2 g of ferric nitrate nonahydrate and dissolve it in 15 mL of deionized water to form solution B; slowly add the obtained clear solution B to solution A, and stir magnetically at room temperature for 2 h to form colloidal solution C. Take a size of about 1×2 cm 2 The carbon cloth (CC) was soaked in colloidal solution C for about 1 h, taken out, put into an oven, and dried at 60 °C for 6 h. Weigh 0.1 g of sulfur powder and transfer it into a semi-closed porcelain boat, then transfer the impregnated carbon cloth (CC) into the porcelain boat, and then transfer it to a temperature-programmed tube furnace. Under the protection of Ar gas, the The temperature-programmed tube furnace was heated to 400 °C at a heating rate of 10 °C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com