Method and device for treating malodorous exhaust gas by low-temperature plasma cracking oxidation reactor

A low-temperature plasma and oxidation reactor technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of large floor area, secondary pollution, uneven gas distribution, etc., and achieve low operating costs, No secondary pollution, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

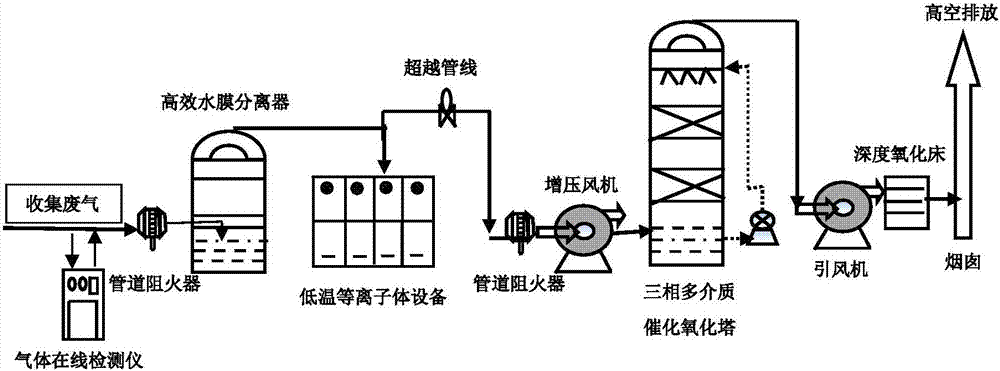

[0022] The present invention will be further explained below in conjunction with accompanying drawing:

[0023] like figure 1 Shown, a kind of method that low-temperature plasma cracking oxidation reactor handles malodorous waste gas, it comprises the following steps:

[0024] (1) The exhaust gas is treated by a high-efficiency water membrane separator, and the temperature is pre-cooled at the same time;

[0025] (2) The exhaust gas then passes through the low-temperature plasma equipment;

[0026] (3) The exhaust gas enters the three-phase multi-media catalytic oxidation tower for further degradation;

[0027] (4) The deep oxidation bed completely decomposes the remaining small amount of ozone.

[0028] Among them, the exhaust gas is collected through the exhaust gas collection system, and the concentration of volatile organic gases is monitored by the gas online detector, and then enters the high-efficiency water membrane separator for treatment.

[0029] In the step (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com