Selective emitter junction and tunneling oxide efficient N-type battery preparation method

A technology of tunnel oxidation and emitter junction, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of high equipment cost, little improvement in electrical performance, poor repeatability, etc., to improve the composite speed and achieve large-scale Mass production, reducing the effect of frontal compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

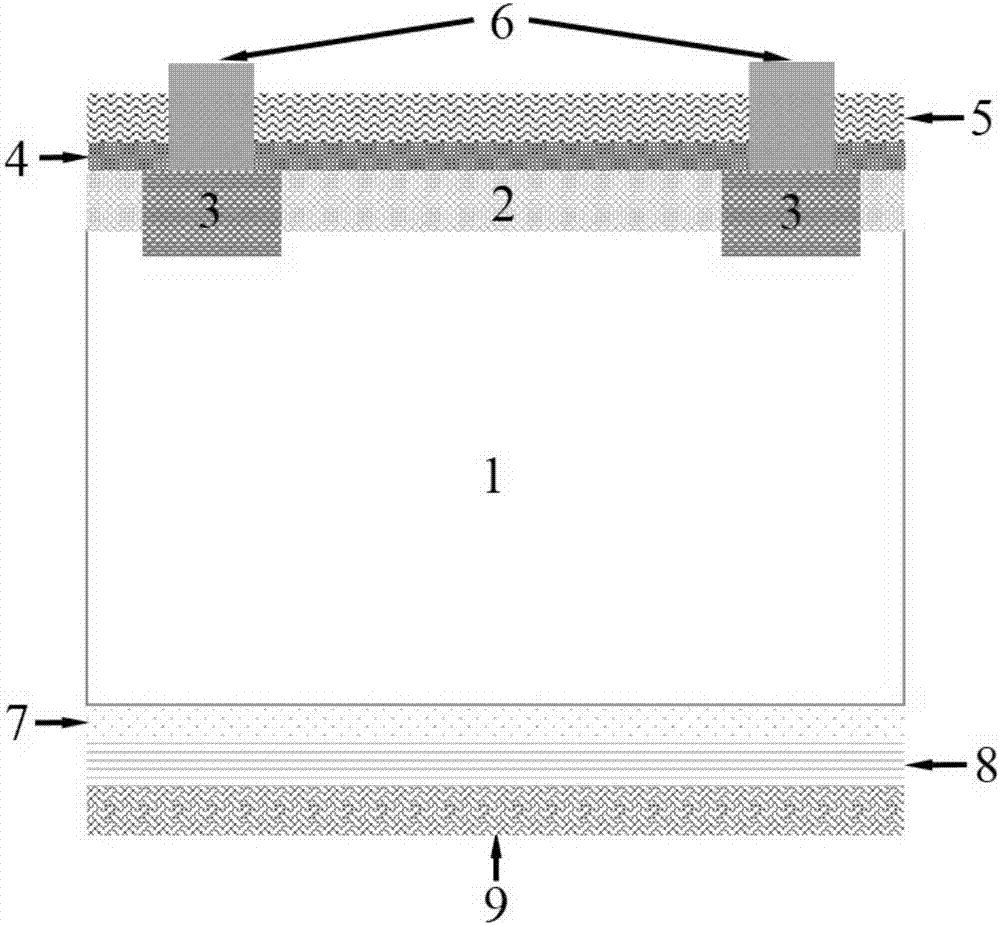

[0034] Selective emitter junction and tunnel oxidation high-efficiency N-type battery preparation method, the method uses the following steps, the structure of the prepared crystalline silicon battery is as follows figure 1 Shown:

[0035] (1) In alkaline solution, remove the damaged layer of silicon chip 1, and carry out texturing to silicon chip 1, the temperature of alkaline solution is 45 ℃, pH value is 8, concentration is 1.5%, after making texture, in silicon chip 1 double A 1 μm pyramidal texture is formed on the surface.

[0036] (2) Boron doping is carried out in the boron source high-temperature diffusion furnace tube, the temperature is 800 ° C, the diffusion time is 10 minutes, and then a mixed gas of oxygen and nitrogen is introduced to push the junction to form a boron-doped P+ emitter junction 2, and the boron-doped The concentration is 1×10 19 cm -3 , the junction depth is controlled at 0.4μm;

[0037] (3) Laser doping is performed on the surface of the bor...

Embodiment 2

[0046] Selective emitter junction and tunnel oxidation high-efficiency N-type battery preparation method, the method uses the following steps, the structure of the prepared crystalline silicon battery is as follows figure 1 Shown:

[0047] (1) In alkaline solution, remove the damaged layer of silicon chip 1, and carry out texturing to silicon chip 1, the temperature of alkaline solution is 65 ℃, pH value is 9, and concentration is 2.5%, after making texture, in silicon chip 1 double The surface is formed with 8 μm pyramid suede.

[0048] (2) Boron doping is carried out in the boron source high-temperature diffusion furnace tube, the temperature is 1000°C, the diffusion time is 100min, and then a mixed gas of oxygen and nitrogen is introduced to push the junction to form a boron-doped P+ emitter junction 2, and the boron-doped The concentration is 1×10 21 cm -3 , the junction depth is controlled at 2 μm.

[0049] (3) Boron-doped P + Laser doping is performed on the surface...

Embodiment 3

[0058] Selective emitter junction and tunnel oxidation high-efficiency N-type battery preparation method, the method uses the following steps, the structure of the prepared crystalline silicon battery is as follows figure 1 Shown:

[0059] (1) In the alkaline solution, remove the damaged layer of the silicon chip 1, and carry out texturing to the silicon chip 1, the temperature of the alkaline solution is 85 ℃, the pH value is 11, and the concentration is 3%. The surface is formed into a 5 μm pyramid suede.

[0060] (2) Boron doping is carried out in the boron source high-temperature diffusion furnace tube, the temperature is 900 ° C, the diffusion time is 60 minutes, and then a mixed gas of oxygen and nitrogen is introduced to push the junction to form a boron-doped P+ emitter junction 2, and the boron-doped The concentration is 1×10 20 cm -3 , the junction depth is controlled at 1 μm.

[0061] (3) Boron-doped P + Laser doping is performed on the surface of the emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com