Composite nanocapsule-injectable hydrogel double-drug-loading sustained release system and preparation method thereof

A dual drug-loading and nanocapsule technology, applied in the field of biomedicine, can solve the problems of short biological half-life and low image contrast of ultrasound imaging, and achieve the effects of controlling drug release, improving contrast, and prolonging drug action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention provides a preparation method of a composite nanocapsule-injectable hydrogel dual drug-loaded slow-release system, comprising the following steps:

[0064] Step 1, preparing a composite nanocapsule encapsulating the drug;

[0065] Step 2, add an equal volume of crosslinking agent aqueous solution with a weight percentage of 0.2 wt% to 10 wt% to the high molecular polymer aqueous solution with a weight percentage of 4wt% to 20wt%, and stir at 20°C to 50°C After uniformity, let it stand for 4 to 20 hours to obtain an injectable hydrogel;

[0066] Step 3. Mix the composite nanocapsule obtained in step 1 and the injectable hydrogel obtained in step 2 according to the weight-to-volume ratio of 1:3 to 1:5 to obtain a composite nanocapsule-injectable hydrogel dual drug-loaded buffer interpretation system;

[0067] Wherein, in the step 2, the crosslinking agent is 1,4-butanediol diepoxy ether and glutaraldehyde.

[0068] In a preferred embodiment of the present...

Embodiment 1

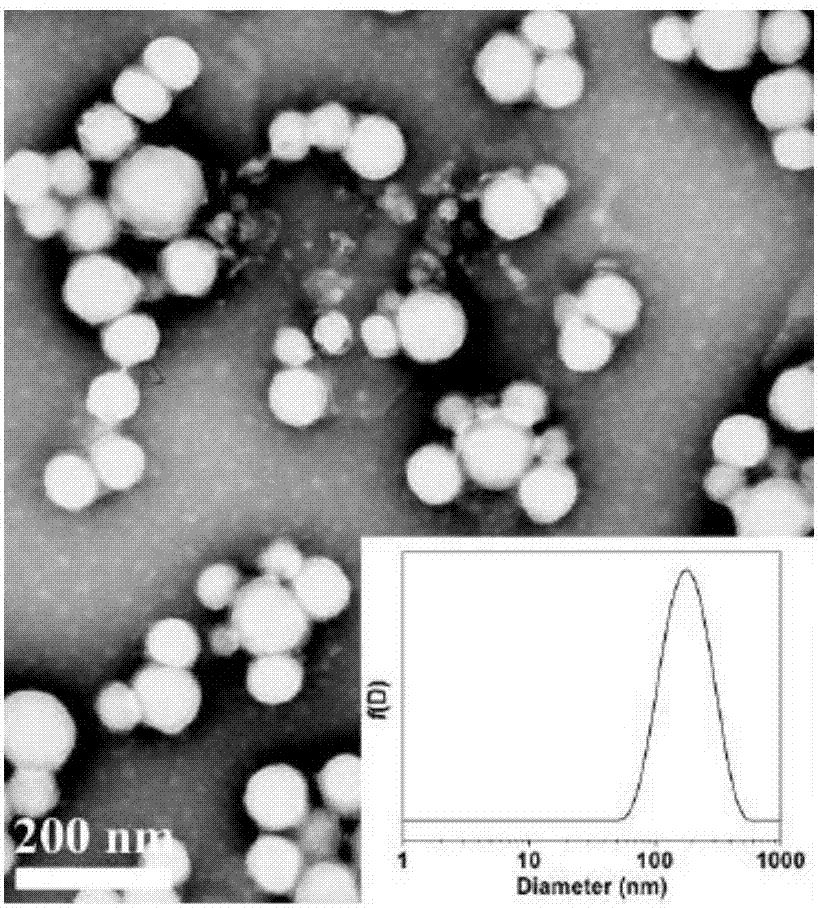

[0092] Embodiment 1, the preparation of composite nanocapsule

[0093]Mix 1ml lidocaine hydrochloride injection with 5ml polylactic acid-polyethylene glycol polymer (PLA-MPEG) in dichloromethane solution, wherein the molecular weight of PLA-MPEG polymer is 20000, m(MPEG):m(PLA )=1:3, the concentration of lidocaine hydrochloride injection is 20mg / ml, the concentration of polylactic acid-polyethylene glycol is 25mg / ml, the power of 150W is used for ultrasonic emulsification for 30s, and then polyvinyl alcohol with a mass fraction of 4% is added Aqueous solution 10ml, use the power of 90W for the second ultrasonic emulsification for 30s. Then add 20 ml of polyvinyl alcohol aqueous solution with a mass fraction of 0.1%, and stir magnetically at room temperature for 6 hours. After the methylene chloride is completely volatilized, centrifuge the obtained water / oil / water emulsion at a rate of 12,000 rpm for 20 minutes, and repeat washing-ultrasonic dispersion-centrifugation The proc...

Embodiment 2

[0095] Embodiment 2, the preparation of composite nanocapsule

[0096] Mix 1ml of procaine hydrochloride injection with 5ml of poly(lactic-co-glycolic acid)-polyethylene glycol polymer (PLGA-PEG) in dichloromethane, wherein the molecular weight of PLGA-MPEG polymer is 20000, LA:GA =50:50, m(MPEG):m(PLA)=1:3, the concentration of procaine hydrochloride injection is 5mg / ml, the concentration of PLGA-PEG is 50mg / ml, and the power of 150W is used for phacoemulsification for 30s, Then add 20ml of polyvinyl alcohol aqueous solution with a mass fraction of 1%, and use 90W power for the second ultrasonic emulsification for 30s. Then add 20 ml of polyvinyl alcohol aqueous solution with a mass fraction of 0.1%, and stir magnetically at room temperature for 6 hours. After the methylene chloride is completely volatilized, centrifuge the obtained water / oil / water emulsion at a rate of 12,000 rpm for 20 minutes, and repeat washing-ultrasonic dispersion-centrifugation The process was perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com