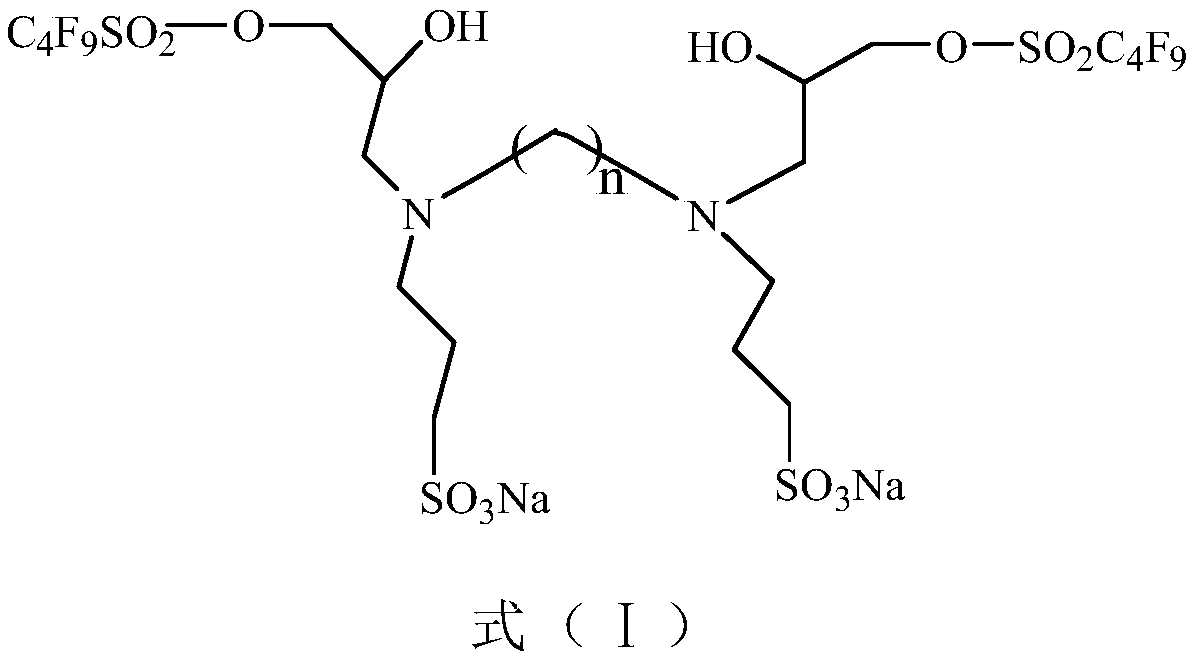

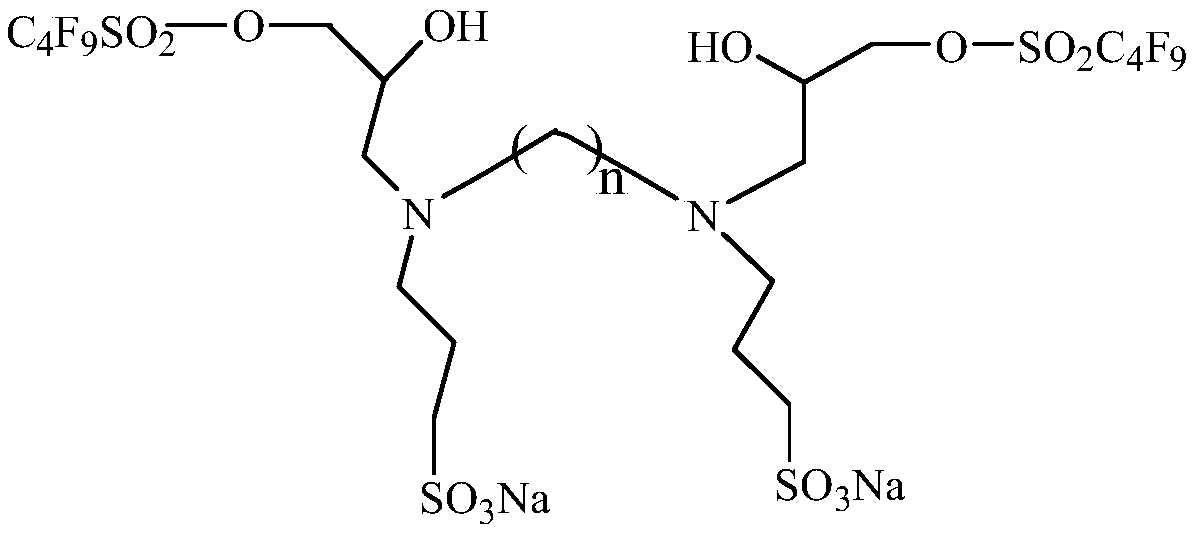

Aqueous film-forming foam fire extinguishing agent based on c4 twinned fluorosurfactant

A technology of fluorosurfactant and foam fire extinguishing agent, which is applied in the field of fire-fighting consumables, can solve the problems of high product cost, cumbersome purification steps, complicated process, etc., and achieve good recombustion resistance and sealing performance, high fire extinguishing efficiency and long storage period long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of C4 twinned fluorosurfactant:

[0039] Perfluorobutylsulfonyl fluoride C 4 f 9 SO 2 F reacts with glycidol to prepare glycidyl perfluorobutanesulfonate: add perfluorobutylsulfonyl fluoride to tetrahydrofuran solution of glycidol and triethylamine at 0°C, heat up to 50°C after all addition, and stir for reaction After 5 hours, the reaction was cooled down to room temperature, the solvent and excess triethylamine were evaporated to dryness under reduced pressure, the residue was washed with water until pH=7.5 of the lotion, and a white solid was obtained after vacuum filtration under reduced pressure, which was vacuum-dried at 60°C for 24 hours to obtain complete Glycidyl fluorobutane sulfonate, a white solid. The molar ratio of raw materials is perfluorobutylsulfonyl fluoride: glycidol: triethylamine=1:1.1:1.6.

[0040] Preparation of fluorine-containing intermediates by ring-opening reaction between glycidyl perfluorobutanesulfonate and alkyldiamine: d...

Embodiment 2

[0047] The preparation method of the C4 twinned fluorosurfactant is the same as in Example 1, and n=2 in the structural formula of the obtained C4 twinned fluorosurfactant.

[0048] In 2000 liters of reactors, add deionized water 500kg, add sodium decylsulfonate (C 10 h 21 SO 3 Na) 30kg, Xanthan Gum 10kg, Urea 20kg, Ethylene Glycol Monobutyl Ether 10kg, 1,2-Propanediol 40kg, stir to make it fully dissolved, slowly add F4H6 80kg, stir to dissolve, then add trimethylol Aminomethane aqueous solution 1kg, sodium benzoate 2kg, edetate disodium salt 1kg, benzotriazole 1kg, deionized water 305kg, stirred for 1 hour to obtain a colorless and clear homogeneous solution, that is, the total mass is 1 ton, which is 6 % type aqueous film-forming foam fire extinguishing agent.

Embodiment 3

[0050] The preparation method of the C4 twinned fluorosurfactant is the same as in Example 1, and n=2 in the structural formula of the obtained C4 twinned fluorosurfactant.

[0051] In 2000 liters of reactors, add deionized water 500kg, add lauryl betaine (C 12 h 25 N + (CH 3 ) 2 -CH 2 -COO - ) 30kg, xanthan gum 1kg, water-soluble starch 4kg, ethylene glycol monobutyl ether 30kg, glycerin 40kg, stir to make it fully dissolved, slowly add F4H3 60kg, stir to dissolve, then add trimethylolamino 1kg of methane aqueous solution, 2kg of formaldehyde aqueous solution, 1kg of EDTA disodium salt, 1kg of benzotriazole, 330kg of deionized water, stirred for 1 hour to obtain a colorless and clear homogeneous solution, that is, the total mass is 1 ton, which is 6% Aqueous film-forming foam fire extinguishing agent.

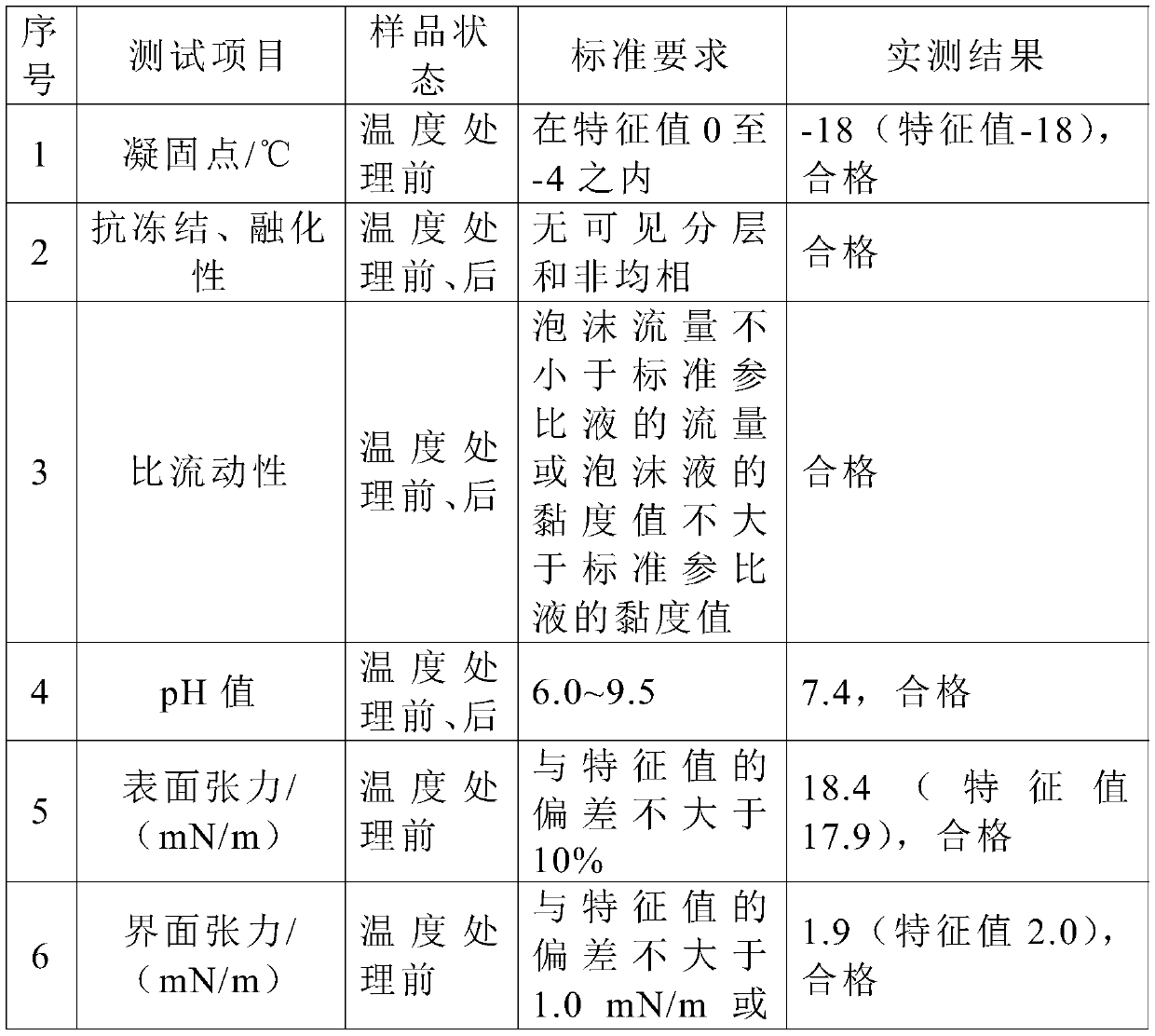

[0052] The 6% aqueous film-forming foam fire extinguishing agent obtained in the above-mentioned embodiments 1-3 is self-inspected according to GB15308-2006 "Foam Fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com