Rear end pumped miniaturized visible light wavelength range surface-emitting semiconductor laser

A wavelength range, semiconductor technology, used in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of lasers that cannot be miniaturized, reduce the efficiency of fundamental frequency infrared light, reduce the output power of visible light, etc., to improve the frequency doubling conversion. Efficiency, reduced thermal effects, mechanically stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

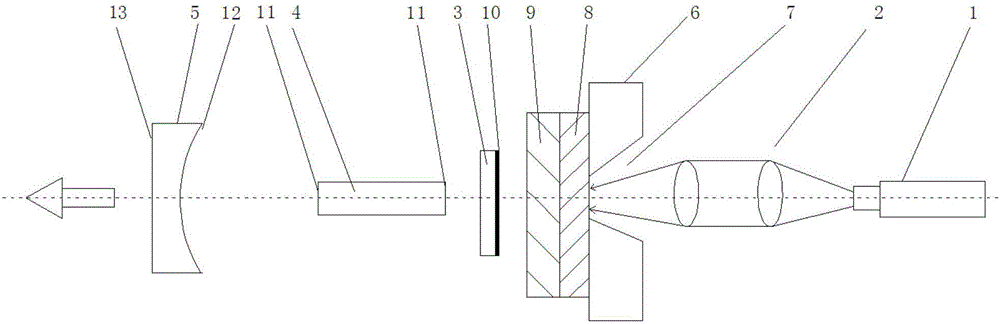

[0025] Back-end pumped miniaturized surface-emitting semiconductor laser in the visible wavelength range, including pump light source 1, collimating and focusing lens group 2, semiconductor gain chip, reflective flat plate 3, and nonlinear crystal from back to front along the optical axis 4 and outcoupling mirror 5;

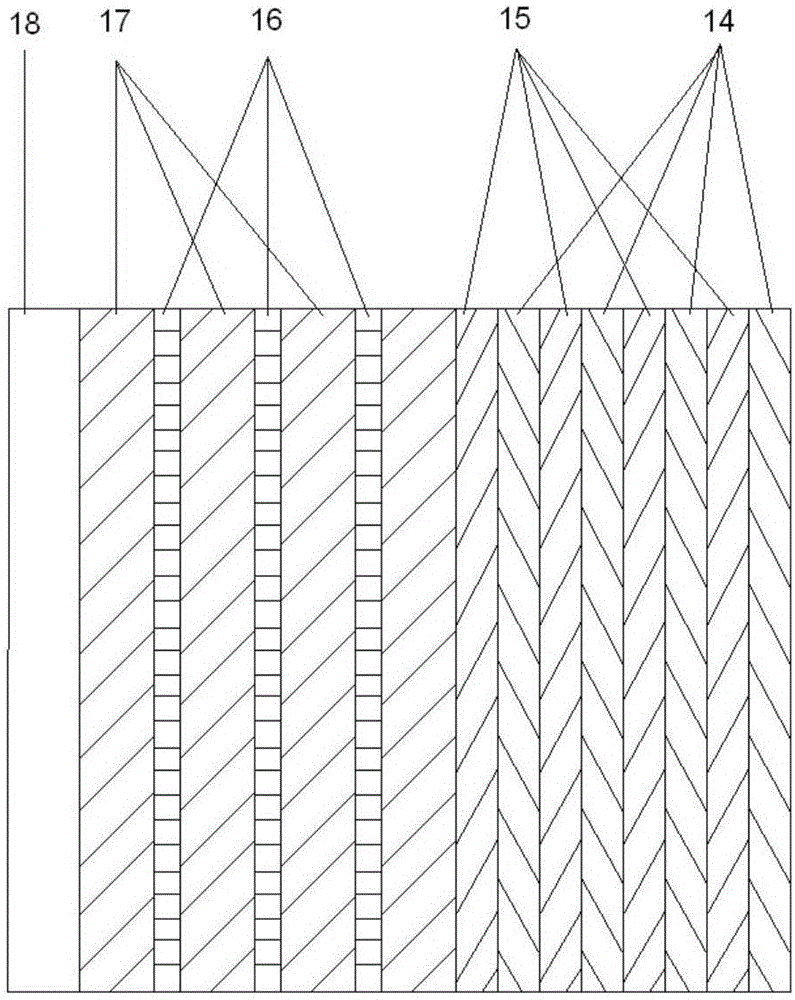

[0026] The semiconductor gain chip is bonded on the heat sink 6 of the bandpass light hole 7; the semiconductor gain chip sequentially includes a first layer with high transmittance to the pump light and high reflectivity to the fundamental frequency infrared laser from back to front. A reflective film 8 and an active region layer 9 for generating a fundamental frequency infrared laser; the nonlinear crystal 4 is used for frequency doubling of the fundamental frequency infrared laser and generating visible light; the reflective flat sheet 3 is inserted in front of the semiconductor gain chip, The reflective flat plate 3 includes a flat plate body and a second ref...

Embodiment 2

[0036] The pump light source is an 808nm semiconductor laser, the collimation and focusing system is a plano-convex lens group with a focal length of 15mm, the heat sink is made of copper material, and the diameters of the large and small circles of the truncated conical aperture are 12mm and 3.5mm respectively.

[0037] The material of the high refractive index layer of the first reflection film in the semiconductor gain chip is Al 0.2 GaAs, the material of the low-refractive index layer is AlAs, and the optical thickness of the two layers is 1 / 4 of the fundamental frequency infrared light wavelength 976nm. The well layer of the quantum well in the active region in the semiconductor gain chip is 8nm thick In 0.13 GaAs material, the barrier layer is GaAs material with a thickness of 130nm. The outermost high barrier layer in the semiconductor gain chip is 207nm thick Al 0.6 GaAs material.

[0038] The rear side of the reflective flat sheet is coated with a second reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com