A lithium silica permanganate -lithium siliconate/carbon composite material and preparation method of alkaline soil metal ions

A carbon composite material, silicomanganic acid-based technology, applied in the direction of nanotechnology, nanotechnology, structural parts, etc. for materials and surface science, can solve the problem of low electronic conductivity and ion diffusivity, can not meet the growing demand, Restricting the promotion and application and other issues, to achieve the effect of improving rate performance, improving electrochemical performance, and shortening diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

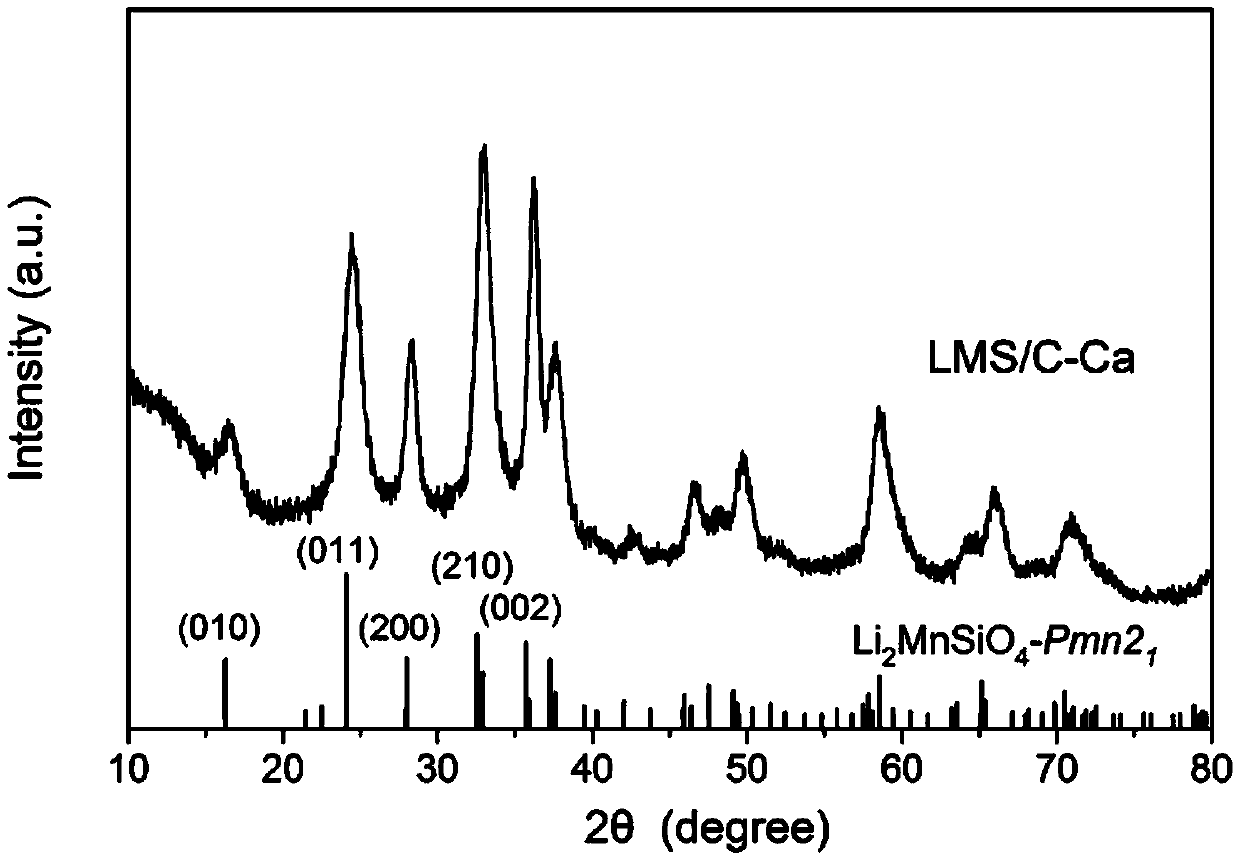

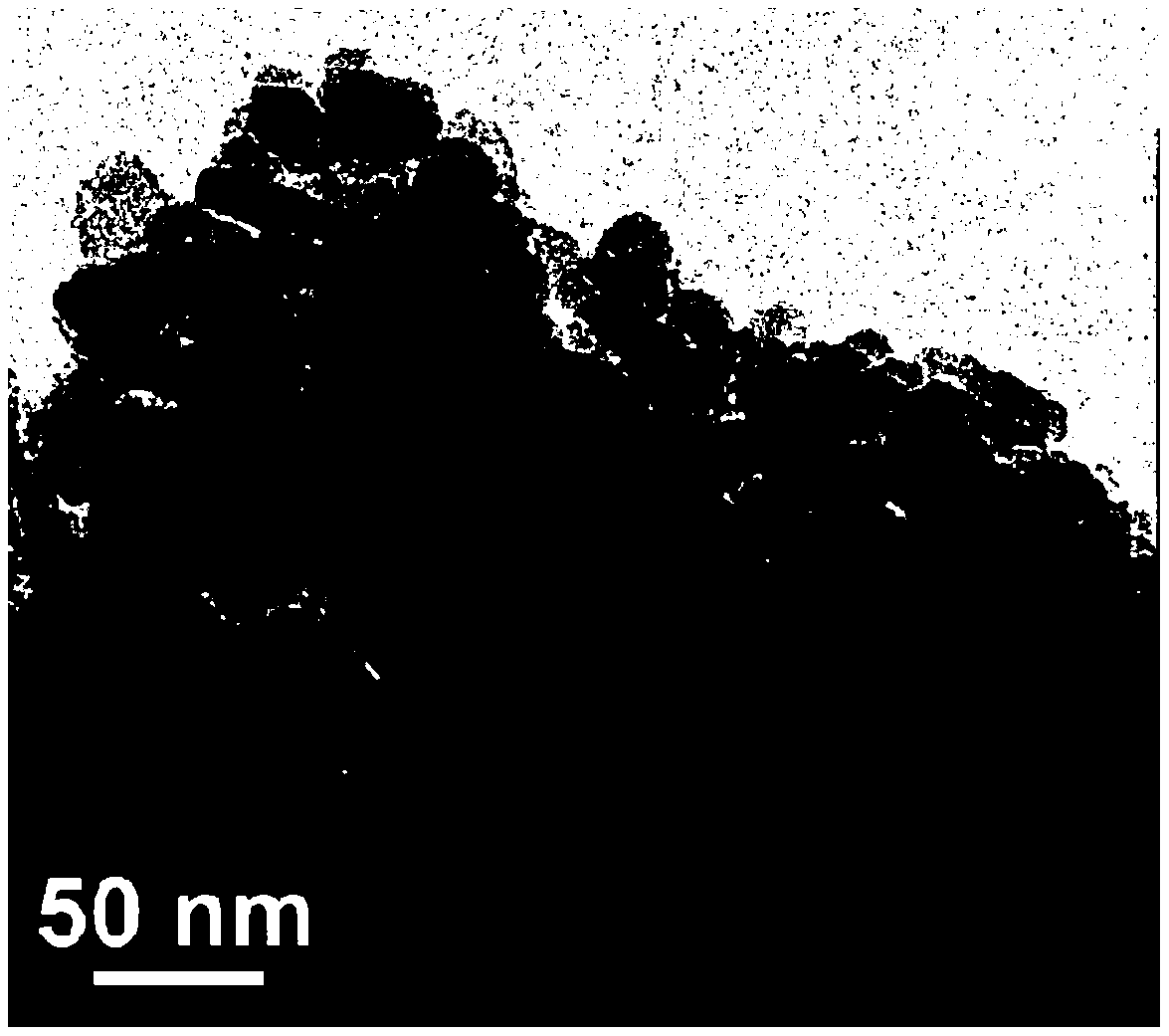

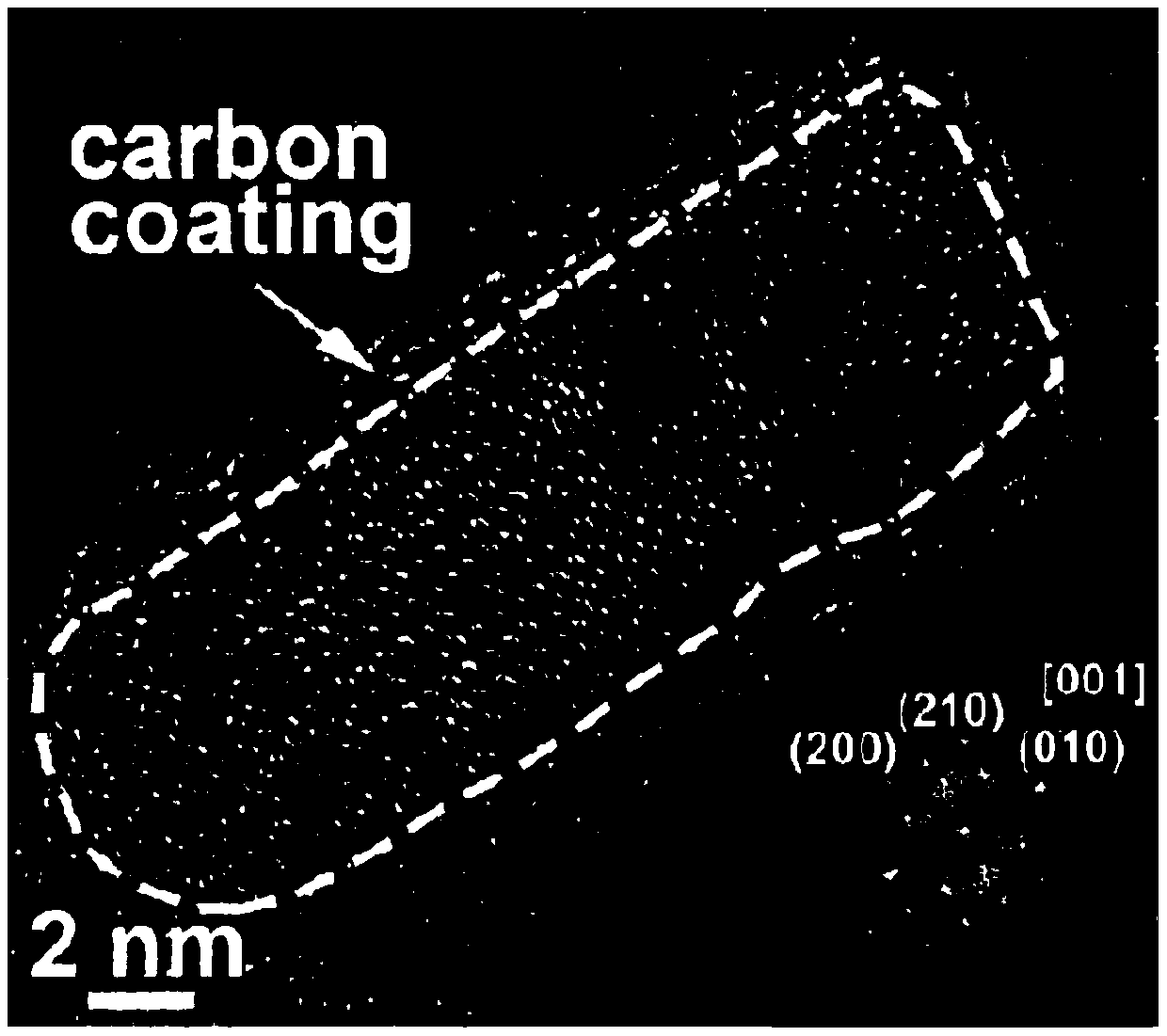

[0027] A kind of silicon manganese acid-based lithium / carbon composite material, the general chemical formula is Li 2 mn 0.95 Ca 0.05 SiO 4 / C, the mass of carbon in the material accounts for 19-20% of the total mass of the material; the material is tested and analyzed by XRD, such as figure 1 As shown, the material is orthorhombic, Pmn2 1 space group; after determination, the b-axis of the material unit cell parameter is a axis is The c axis is figure 2 For pictures under a high-resolution transmission electron microscope, such as figure 2 As shown, the material is in the shape of 2-20nm nano-rods or nano-sheets. figure 2 Fourier transform (FFT) of the picture is obtained image 3 , as shown in the figure, is a picture of diffraction spots. After calibration, it is found that these crystal grains are [001] with axes, showing the characteristics of (001) crystal plane exposure; the X-ray photoelectron spectroscopy test is carried out on the material, and the re...

Embodiment 2

[0030] The composite material of embodiment 1 is prepared according to the following steps:

[0031] (I) At room temperature, weigh 40mmol of LiOH and dissolve it in 40mL of diethylene glycol to make the pH value 10, then add 10mmol of tetraethyl silicate and stir for 50 minutes until the tetraethyl silicate is completely Dissolve to obtain solution A, wherein the molar mass ratio of Li element and Si element is 4:1; 9.5mmolMnCl 2 4H 2 O and 0.5 mmol CaCl 2 Dissolve in 20mL of diethylene glycol to obtain solution B;

[0032] (II) Add solution B prepared in step (I) dropwise to solution A, keep the pH value of the system constant, then mix the solution under 4Mpa pressure, react at 230°C for 72 hours, then cool naturally to room temperature; After centrifugation, the product was centrifugally washed with deionized water and ethanol for several times until the solvent after washing was neutral, and then the solid product was vacuum-dried at 80°C to obtain Li 2 mn 0.95 Ca 0...

Embodiment 3

[0035] A kind of silicon manganese acid-based lithium / carbon composite material, the general chemical formula is Li 2 mn 0.95 Mg 0.05 SiO 4 / C, the mass of carbon in the material accounts for 19-20% of the total mass of the material; the material is orthorhombic through XRD detection and refinement analysis, Pmn2 1 space group, the b-axis of the material unit cell parameter is a axis is The c axis is The material is composed of nanosheets and nanorod particles of 5-50nm. The material shows [001] band axis spots under the high-resolution transmission electron microscope, showing the characteristics of (001) crystal plane exposure; X-ray photoelectron spectroscopy is carried out on the material According to the test, lithium and silicon are enriched on the surface of the material, while manganese and magnesium are enriched in the material.

[0036] The preparation method is as follows:

[0037] (I) At room temperature, weigh 20mmol of LiOH and dissolve it in 40mL of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com