A kind of sludge environment-friendly permeable brick and its preparation method

An environmentally friendly, permeable brick technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problem that water permeability, flexural strength, wear resistance and freeze-thaw resistance are difficult to meet the requirements, and cracks or cracks are easy to appear. Angle, the production process is not mature enough, etc., to achieve the effect of easy mixing and molding processing, reasonable matching and proportion, and low comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

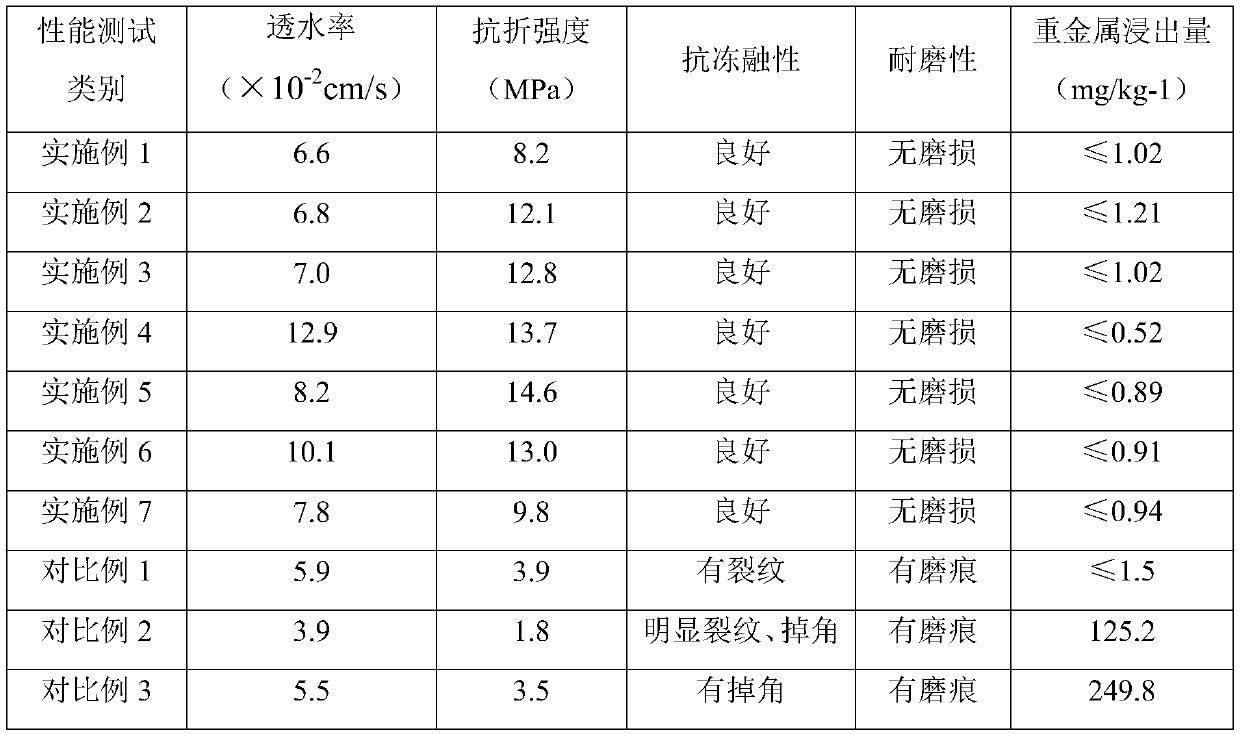

Examples

preparation example Construction

[0021] As a preferred implementation mode, the preparation methods of the permeable bricks described in the following examples and comparative examples all include the following steps: Ⅰ. Measure each raw material into the stirring container in sequence according to weight percentage; Ⅱ. Add 2 to 20 Stir the mixed material with % water; Ⅲ. The mixed material is pressed and formed by a hydraulic press; Ⅳ. Curing the formed brick adobe at room temperature for 12-48 hours;

[0022] The inventors found that adjusting within the parameter range limited by the above preparation method has little effect on the efficacy of the prepared permeable brick, so the above method is the preferred preparation method of the present invention.

[0023] The method of the present invention will be further described below by taking specific implementation conditions as an example.

Embodiment 1

[0025] A sludge-friendly environment-friendly permeable brick, comprising the following raw materials in weight percentage: 70% of waste mud, 10% of coarse sand, 5% of silicon-aluminum-iron-calcium oxide, and 15% of cement; : 1 by weight ratio; the silicon-aluminum-iron-calcium oxide is mixed by fly ash, fine coal slag, and slag powder in a weight ratio of 2:0.5:1.

[0026] The moisture content of the sludge and the sludge is 12wt% after being treated with a special curing agent, and then passed through a 50-mesh sieve to obtain mud powder after pressure filtration, drying and roller grinding; the special curing agent is expansive soil, polypropylene A mixture of fiber, ferric chloride, cement, chitosan and quicklime, wherein the content of chitosan is 5%.

[0027] The particle size of the silicon-aluminum-iron-calcium oxide is ≤1mm.

[0028] More than 80% of the coarse sand has a particle size of 1-2 mm.

[0029] The preparation method of the sludge-friendly environment-fri...

Embodiment 2

[0031] A sludge-friendly environment-friendly permeable brick, comprising the following raw materials in weight percentage: 60% of waste mud, 5% of coarse sand, 5% of silicon-aluminum-iron-calcium oxide, and 30% of cement; the waste mud is silt; the silicon-aluminum Iron-calcium oxide is made by mixing fly ash and fine coal slag at a weight ratio of 2:1.

[0032]The water content of the waste mud is 4wt% after being treated with a special curing agent, and then through a 50-mesh sieve to obtain mud powder after pressure filtration, drying and roller grinding; the content of chitosan in the special curing agent is 3 %.

[0033] The particle size of the silicon-aluminum-iron-calcium oxide is ≤1mm.

[0034] More than 80% of the coarse sand has a particle size of 1-2 mm.

[0035] The preparation method of the sludge-friendly environment-friendly permeable brick comprises the following steps: Ⅰ. Measure each raw material according to the weight percentage and add it to the mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com