Biocatalysis preparation method of high-conductivity poly(3,4-ethylenedioxythiophene)/lignosulfonic acid dispersion liquid

A technology of ethylenedioxythiophene and ligninsulfonic acid, which is applied in the field of conductive polymers, can solve the problems of difficult PEDOT, hindering the application range, and difficult processing, and achieves the effects of high catalytic efficiency, low price, and strong processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

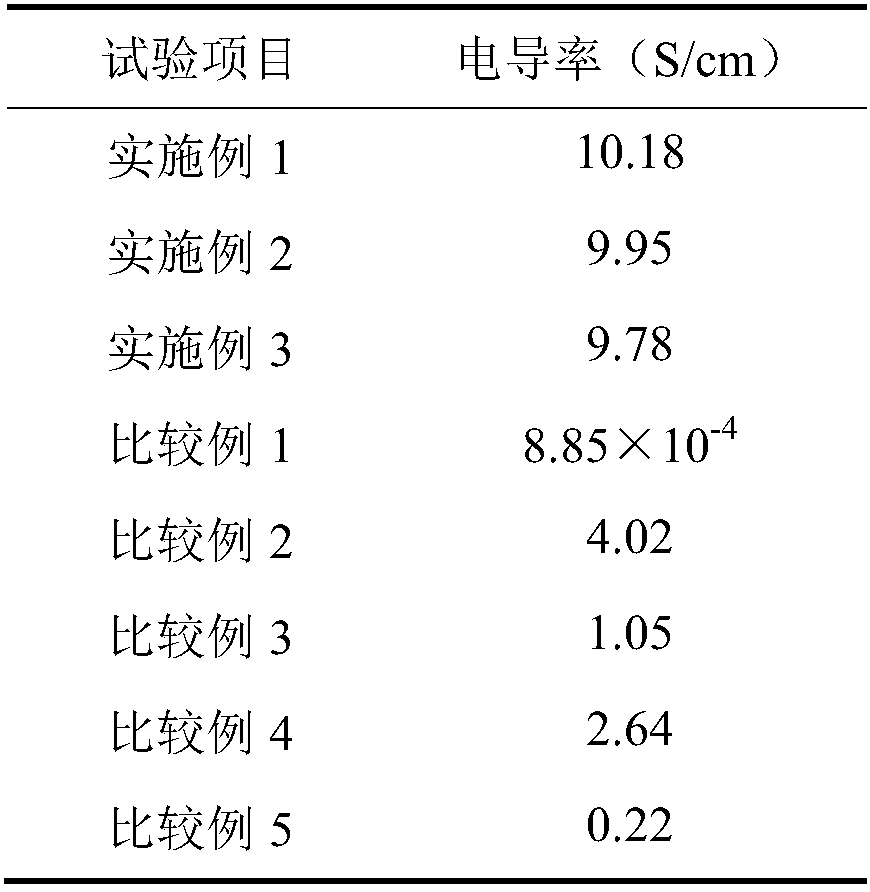

Examples

Embodiment 1

[0032] Weigh lignosulfonic acid, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate according to the mass ratio of 2.8:1:2:2.5 and add high-purity water to form a mixed solution with a solid content of 2.5%. In a water bath environment at 25°C, stir at 6000rpm for 30min, add acetic acid-sodium acetate buffer solution to adjust the pH of the mixture to 6, then add horseradish peroxidase while stirring, and then slowly add hydrogen peroxide solution dropwise , continue to stir and react for 24 hours to obtain a primary reaction solution; weigh the above primary reaction solution, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate in a mass ratio of 1.5:1:2:2.5 and add high-purity water, Make a mixed solution with a solid content of 2%, place it in a water bath environment at 20°C, stir at 7000rpm for 30min, then add horseradish peroxidase while stirring, then slowly add hydrogen peroxide solution dropwise, and stir at 6000rpm Stir and react for 30 hours, ...

Embodiment 2

[0037] Weigh lignosulfonic acid, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate according to the mass ratio of 2.8:1:2:2.5 and add high-purity water to form a mixed solution with a solid content of 2.5%. In a water bath environment at 25°C, stir at 6000rpm for 30min, add acetic acid-sodium acetate buffer solution to adjust the pH of the mixture to 6, then add horseradish peroxidase while stirring, and then slowly add hydrogen peroxide solution dropwise , continue to stir and react for 24 hours to obtain a primary reaction solution; weigh the above primary reaction solution, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate in a mass ratio of 1.5:1:2:2.5 and add high-purity water, Make a mixed solution with a solid content of 2%, place it in a water bath environment at 20°C, stir at 7000rpm for 30min, then add horseradish peroxidase while stirring, then slowly add hydrogen peroxide solution dropwise, and stir at 6000rpm Stir and react for 30 hours, ...

Embodiment 3

[0042]Weigh lignosulfonic acid, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate according to the mass ratio of 2.8:1:2:2.5 and add high-purity water to form a mixed solution with a solid content of 2.5%. In a water bath environment at 25°C, stir at 6000rpm for 30min, add acetic acid-sodium acetate buffer solution to adjust the pH of the mixture to 6, then add soybean peroxidase while stirring, and then slowly add hydrogen peroxide solution dropwise, Continue to stir and react for 24 hours to obtain a primary reaction solution; weigh the above-mentioned primary reaction solution, 3,4-ethylenedioxythiophene, sodium tartrate and sodium oxalate according to the mass ratio of 1.5:1:2:2.5 and add high-purity water to prepare To form a mixed solution with a solid content of 2%, place it in a water bath environment at 20°C, stir at 7000rpm for 30min, then add soybean peroxidase while stirring, then slowly add hydrogen peroxide solution dropwise, and stir at 6000rpm Reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com