Method for depositing metal elementary substance thin film by atmospheric cold plasmas

A cold plasma, metal deposition technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem that the study of metal element thin film has not yet been reported, and meet the requirements of reducing volatility and stability , The effect of low reaction temperature and no need for annealing treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment includes the following steps:

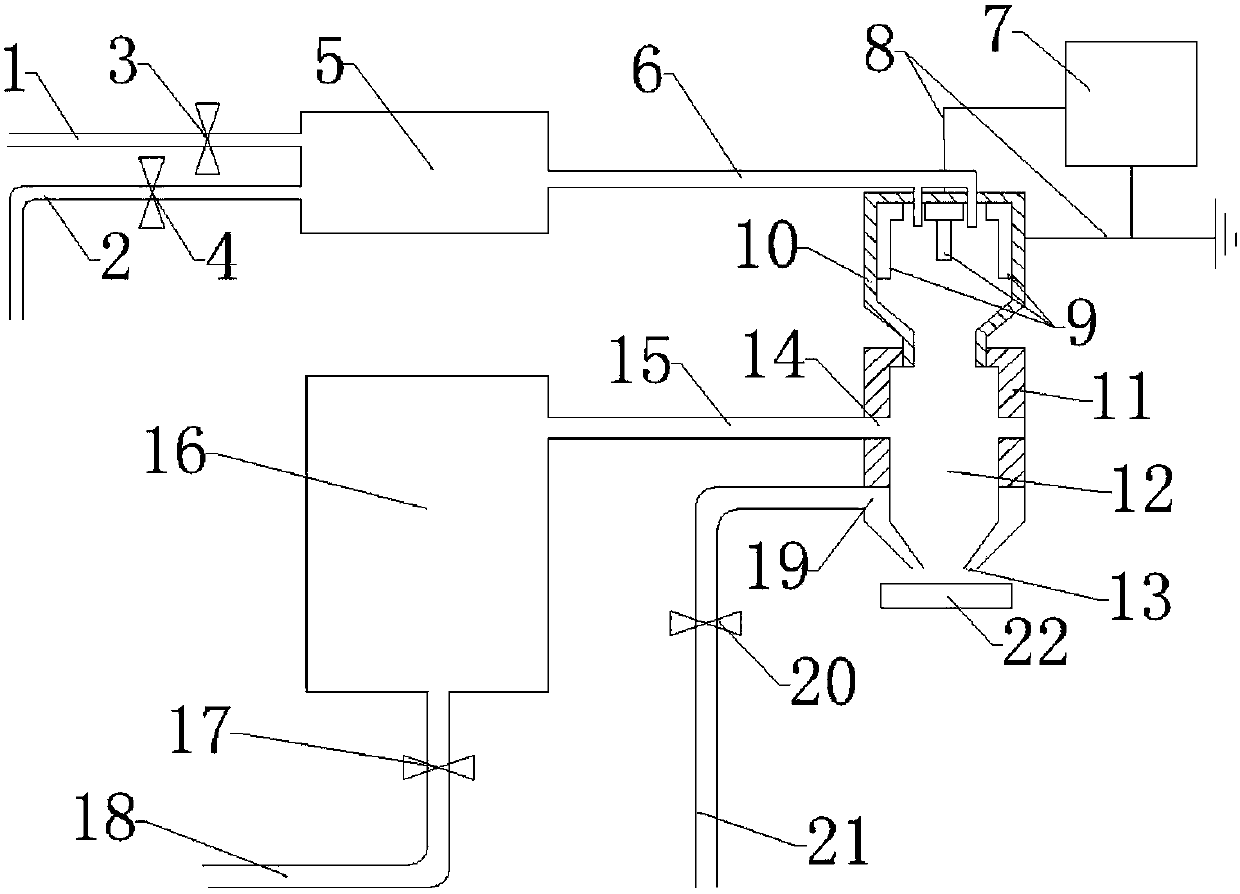

[0040]Step 1, open the first valve 3 and the second valve 4, so that ammonia and nitrogen enter the gas mixing proportioner 5 through the first intake pipe 1 and the second intake pipe 2 respectively, and the gas is mixed according to the volume of 8:92 Perform equal pressure mixing to form a mixed gas with a pressure of 0.25MPa, then transport the mixed gas to the plasma torch 10 through the gas transport pipeline 6, adjust the output power of the plasma power supply 7 to 400W, and discharge the mixed gas at the electrode 9 Ionize under excitation to generate cold jet plasma at normal pressure, and the cold jet plasma at normal pressure forms a plasma flame in the cavity 12 of the nozzle 11;

[0041] Step 2, copper nitrate is mixed with the solution that concentration is 150g / L, is placed in atomization chamber 16, opens the 3rd valve 17, and nitrogen enters in the atomization chamber 16 through the 3rd inlet pipe 18, and...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] Step 1, open the first valve 3 and the second valve 4, so that ammonia and argon enter the gas mixing proportioner 5 through the first inlet pipe 1 and the second inlet pipe 2 respectively, and according to the ratio of 8:92 The volume ratio is mixed at equal pressure to form a mixed gas with a pressure of 0.35MPa, and then the mixed gas is transported to the plasma torch 10 through the gas transportation pipeline 6, and the output power of the plasma power supply 7 is adjusted to be 400W. Ionization under the excitation of the discharge generates atmospheric pressure radio frequency cold plasma, and the atmospheric pressure radio frequency cold plasma forms a plasma flame in the cavity 12 of the nozzle 11;

[0050] Step 2, dissolving bis(hexafluoroacetylacetonate) copper in ethyl acetate to prepare a solution with a concentration of 1.4mol / L, placing it in the atomization chamber 16, closing the third valve 17, and...

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1, open the first valve 3 and the second valve 4, so that ammonia and argon enter the gas mixing proportioner 5 through the first inlet pipe 1 and the second inlet pipe 2 respectively, and according to the ratio of 3:7 The volume ratio is mixed at equal pressure to form a mixed gas with a pressure of 0.80 MPa, and then the mixed gas is transported to the plasma torch 10 through the gas transportation pipeline 6, and the output power of the plasma power supply 7 is adjusted to be 400W. Ionization under the excitation of the discharge generates atmospheric pressure jet flow cold plasma, and the atmospheric pressure jet flow cold plasma forms a plasma flame in the cavity 12 of the nozzle 11;

[0055] Step 2, zinc nitrate is mixed with the solution that concentration is 100g / L, is placed in atomization chamber 16, opens the 3rd valve 17, and nitrogen enters in the atomization chamber 16 through the 3rd inlet pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com