Water-borne acrylic acid modified epoxy ester emulsion containing silicon and preparation method of water-borne acrylic acid modified epoxy ester emulsion

A technology of water-based acrylic and epoxy ester, which can be used in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc. It can solve the problems of poor surface anti-fouling ability, poor medium resistance, and unstable storage. Achieve the effects of reducing permeability, improving various properties, and excellent fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

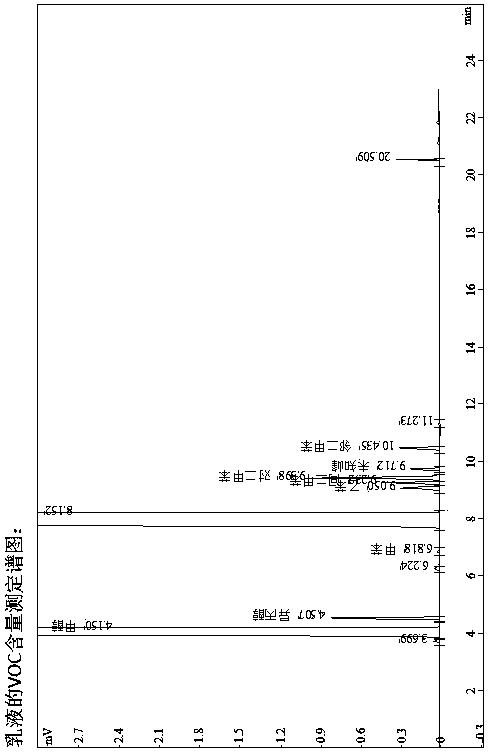

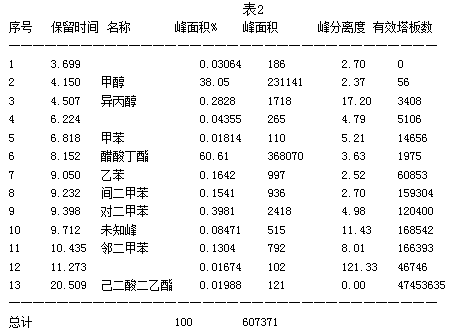

Image

Examples

Embodiment 1

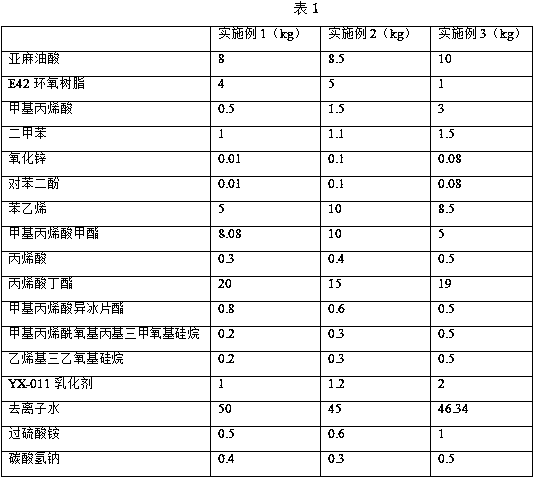

[0037] The amount of raw materials is shown in Table 1. Vinyl triethoxysilane is Z6518 from Dow Corning; methacryloxypropyl trimethoxysilane is KBM-503 from Shin-Etsu; the emulsifier is YX- 011.

[0038] Concrete preparation process is as follows:

[0039] Step A. Preparation of epoxy ester base resin: E42 epoxy resin, linolenic acid, methacrylic acid, zinc oxide, and xylene are heated in a three-necked flask, heated to 180°C and reacted until the acid value is less than 10mgKOH / g, then stop Heating, pumping out reflux xylene, adding hydroquinone and stirring evenly.

[0040] Step B, preparation of functional monomer resin mixture: styrene, methyl methacrylate, acrylic acid, butyl acrylate, isobornyl methacrylate, methacryloxypropyl trimethoxysilane, vinyl trimethoxysilane Ethoxysilane and epoxy ester base resin are mixed and stirred well.

[0041] Step C. Preparation of pre-emulsion: Dissolve 90% of YX-011 emulsifier in one-third of deionized water and stir evenly. Slowly ...

Embodiment 2

[0045]The amount of raw materials is shown in Table 1. The vinyl triethoxysilane is GF56 from Wacker, Germany; the methacryloxypropyl trimethoxysilane is Silquest A-174 from Momentive, USA; the emulsifier is OP from Dow, USA -10.

[0046] Concrete preparation process is as follows:

[0047] Step A. Preparation of epoxy ester base resin: E42 epoxy resin, linolenic acid, methacrylic acid, zinc oxide, and xylene are heated in a three-necked flask, heated to 180°C and reacted until the acid value is less than 10mgKOH / g, then stop Heating, pumping out reflux xylene, adding hydroquinone and stirring evenly.

[0048] Step B, preparation of functional monomer resin mixture: styrene, methyl methacrylate, acrylic acid, butyl acrylate, isobornyl methacrylate, methacryloxypropyl trimethoxysilane, vinyl trimethoxysilane Ethoxysilane and epoxy ester base resin are mixed and stirred well.

[0049] Step C. Preparation of pre-emulsion: Dissolve 90% of YX-011 emulsifier in one-third of deion...

Embodiment 3

[0053] The amount of raw materials is shown in Table 1, and the specific preparation process is as follows:

[0054] Step A, prepare epoxy ester base resin: E42 epoxy resin, linolenic acid, methacrylic acid and zinc oxide, put xylene into a three-necked flask and heat, raise the temperature to 180°C and react until the acid value is less than 10mgKOH / g, then stop Heating, pumping out reflux xylene, adding hydroquinone and stirring evenly.

[0055] Step B, preparation of functional monomer resin mixture: styrene, methyl methacrylate, acrylic acid, butyl acrylate, isobornyl methacrylate, methacryloxypropyl trimethoxysilane, vinyl trimethoxysilane Ethoxysilane and epoxy ester base resin are mixed and stirred well.

[0056] Step C. Preparation of pre-emulsion: Dissolve 90% of YX-011 emulsifier in one-third of deionized water and stir evenly. Slowly add the above-mentioned functional monomer resin mixture during high-speed dispersion to prepare a pre-emulsion for use.

[0057] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com