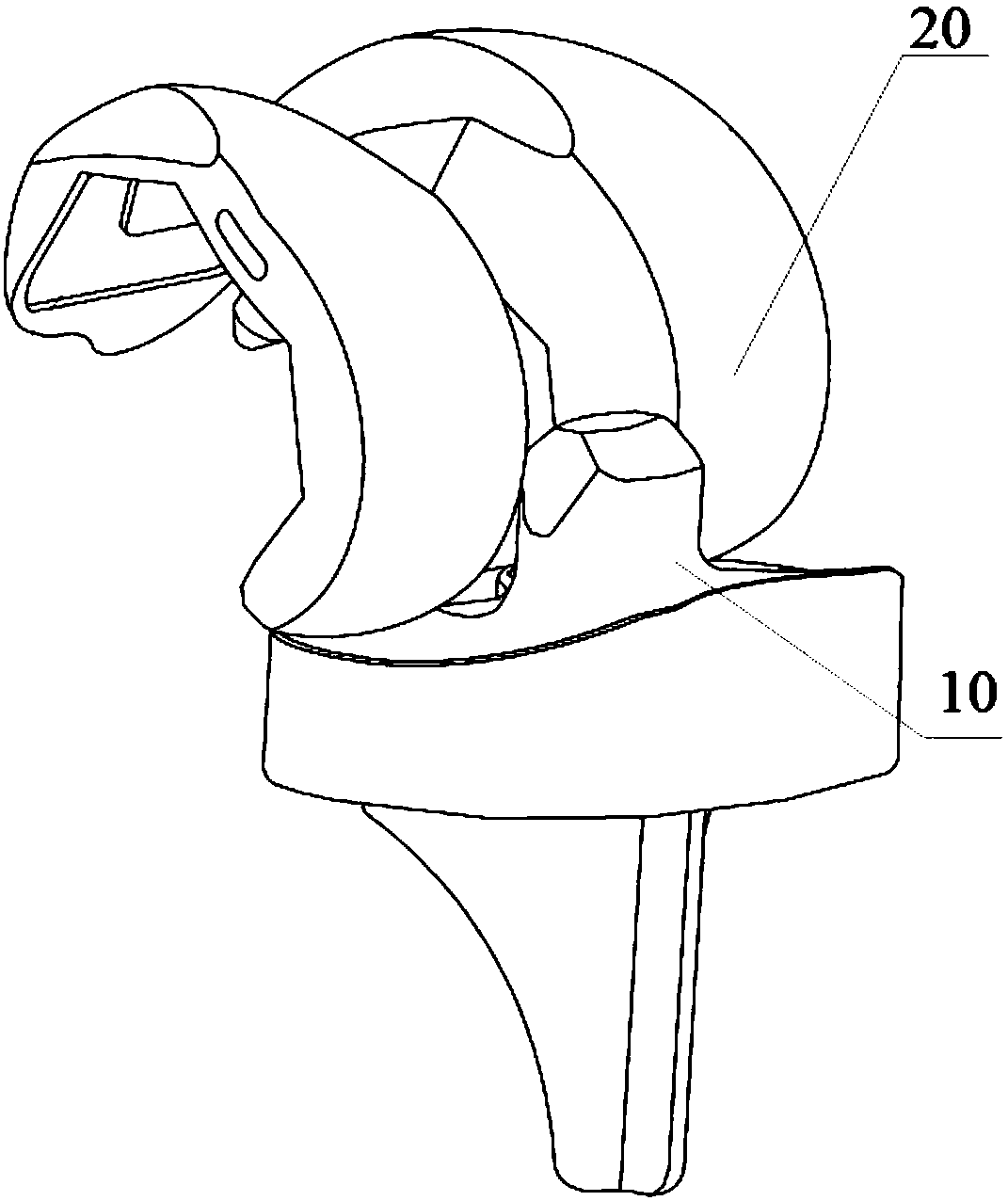

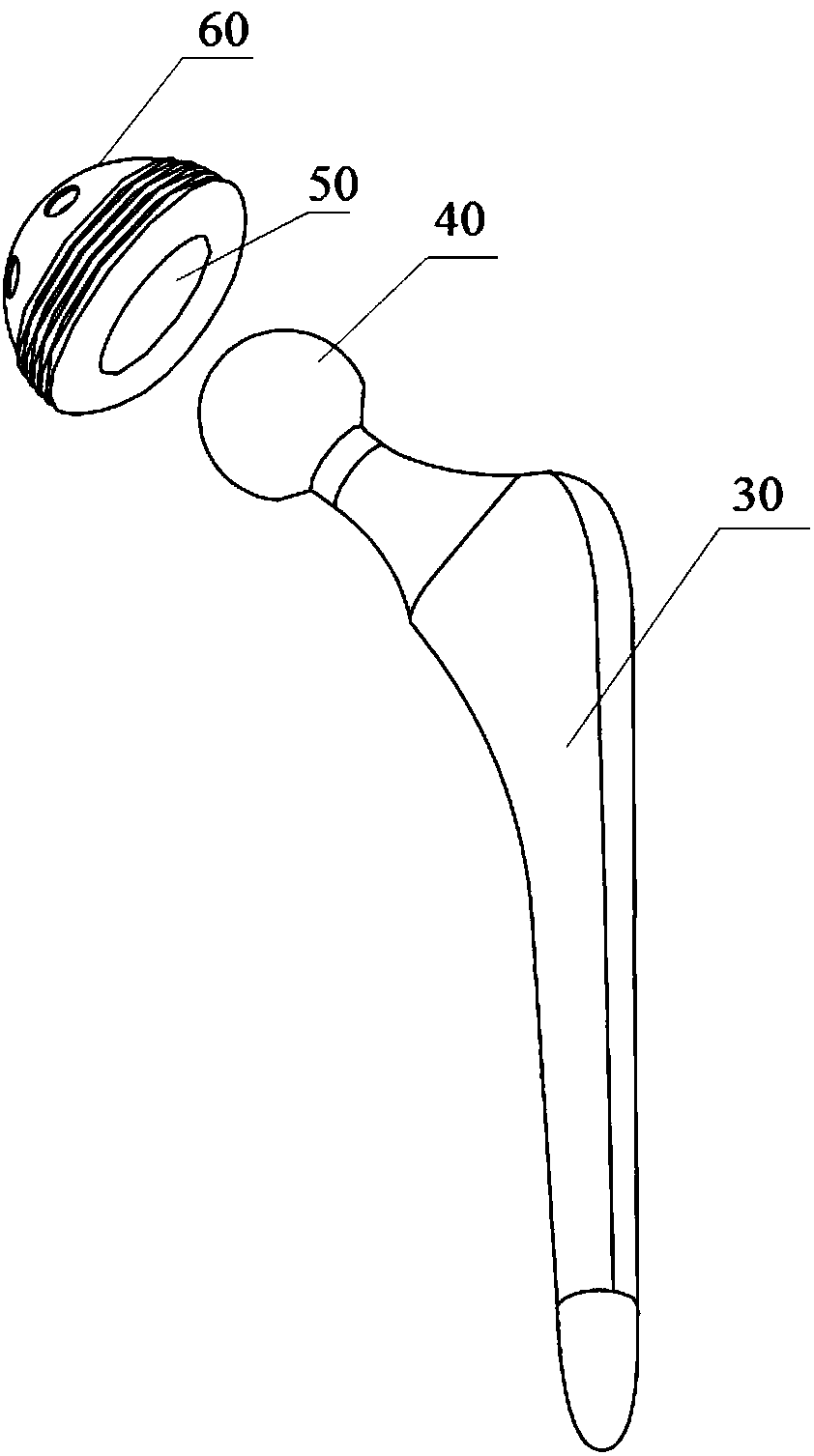

Fluorine modified polyether-ether-ketone/graphite nano composite material and artificial joint prosthesis

A nanocomposite material, polyether ether ketone technology, applied in prostheses, elbow joints, knee joints, etc., can solve problems such as poor osseointegration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

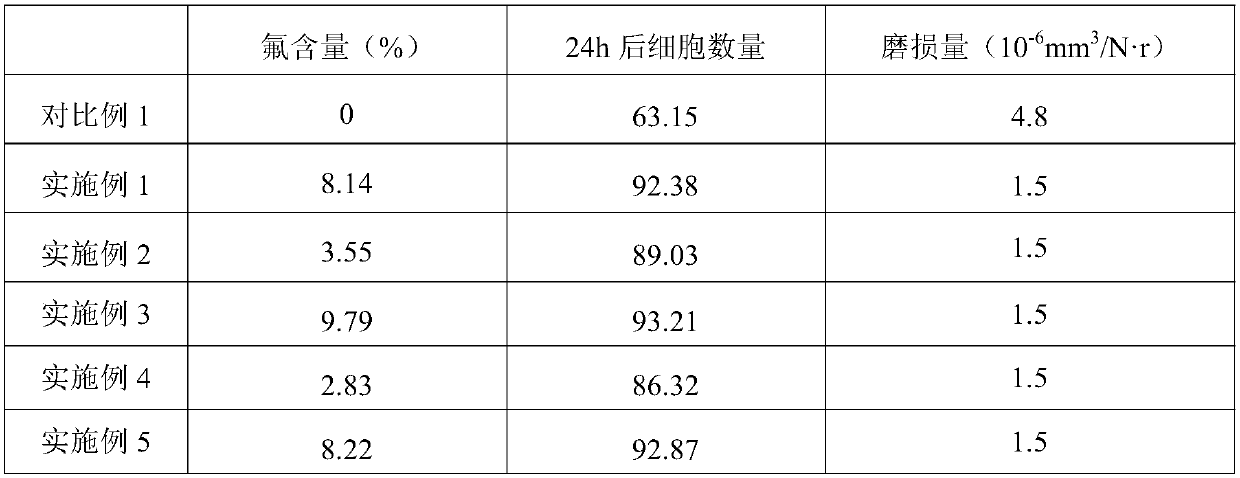

Examples

preparation example Construction

[0039] In addition, the present application also provides a preparation method of fluorine-modified polyetheretherketone / graphite nanocomposite, the preparation method comprising: using a fluorine-containing organic compound as an ion implantation source, and adopting plasma implantation technology to treat polyetheretherketone / graphite The surface of the graphite nanocomposite material is modified with fluorine, and fluorine atoms are loaded on the surface of the polyetheretherketone / graphite nanocomposite material.

[0040] In a preferred embodiment of the present application, the above-mentioned fluorine-containing organic compound is carbon tetrafluoride (CF 4 ), tetrafluoroethylene (C 2 f 4 ), hexafluoropropylene (C 3 f 6 ). Each of the above-mentioned fluorine-containing organic compounds is easy to be plasmaized and does not contain impurity elements.

[0041] In addition, preferably, the pressure of the plasma injection cavity of the above plasma injection technol...

Embodiment 1

[0053] Preparation of expanded graphite: Add natural flake graphite into the mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 4:1), stir at room temperature for 20 hours, wash repeatedly with distilled water until neutral, dry for more than 24 hours to remove water, and prepare the above-mentioned The graphite oxide intercalation compound is treated at high temperature (about 1000°C) for 15s to obtain expanded graphite.

[0054] 12 g of the expanded graphite prepared above was put into an alcohol solution with an ethanol content of 70%, and ultrasonically treated for 6 hours to obtain a nano-graphite microsheet solution. The thickness of the nanographite microflakes is detected by SEM to be between 20nm and 80nm.

[0055] Mix 110g of hydroquinone with the above-mentioned nanographite microflake solution, and ultrasonically mix for 8 hours under nitrogen protection to obtain a hydroquinone / nanographite microflake pre-intercalation solution, and t...

Embodiment 2

[0059] The difference from Example 1 is that the injection process parameters are: the pressure of the working gas is 5.0×10 -2 Pa, the injection voltage is 20kV, the injection pulse width is 60μs, the pulse repetition frequency is 15Hz, the discharge current is 1.5A, and the injection time is 0.5h. A sample of Example 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com