Separation method of magnolia officinalis bisphenol

A separation method and Magnolia officinalis technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficulty in taking into account yield and purity, large solvent consumption, long production cycle, etc., and achieve high separation efficiency. , the method is simple, the effect of low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

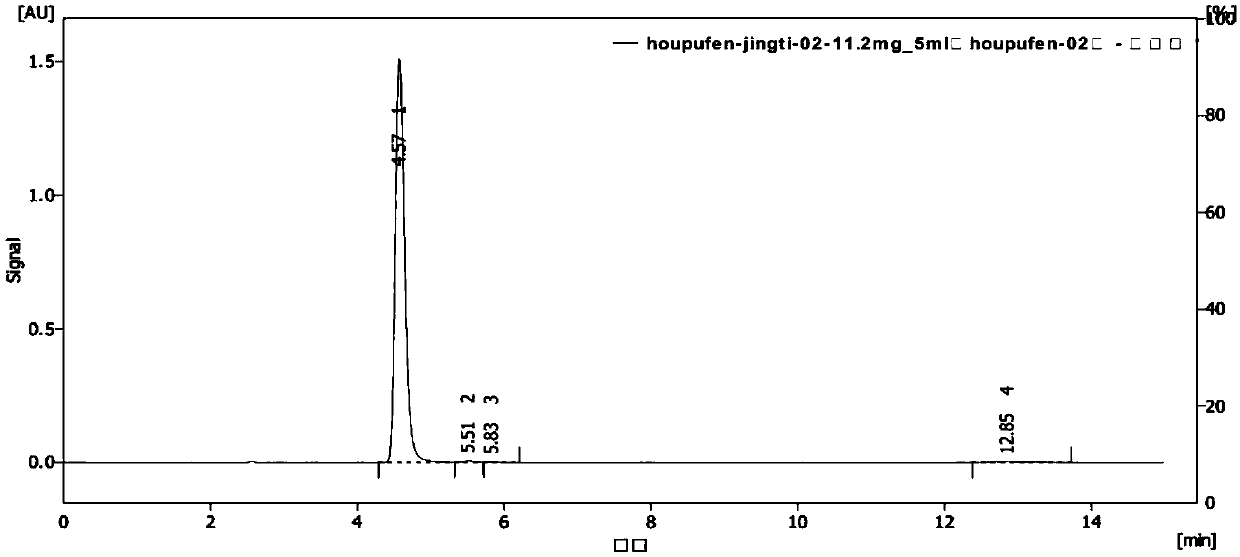

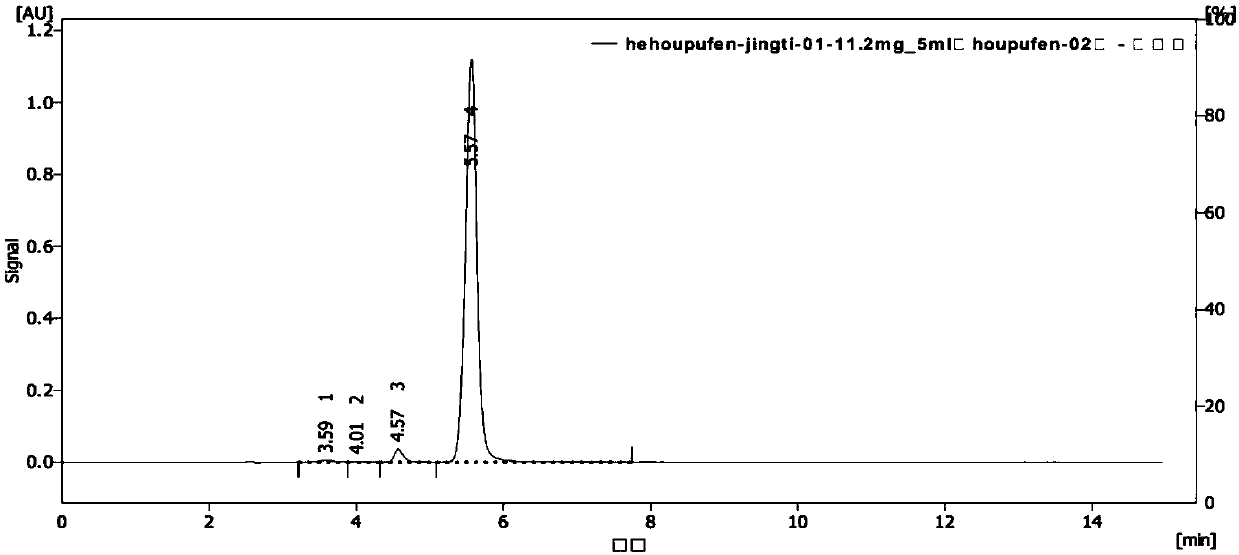

[0057] Thin-layer chromatography processes the extract of magnolobisphenol, adopts different solvents respectively, and concrete solvent is as follows:

[0058] PE: ETOH was mixed with volume ratios of 100:1, 50:1, 40:1, 30:1, 20:1 and 10:1, and the results of the thin-layer plates were as follows figure 1 shown. figure 1 The one on the left of each plate is the control group.

[0059] from figure 1 It can be seen that when the volume ratio of PE to ETOH is 10-20:1, magnolol and honokiol are well separated.

Embodiment 2

[0061] A method for separating magnolobisphenols, comprising the following steps:

[0062] Extraction: Magnolia officinalis bark (which contains 2.9% magnolol and 1.9% honokiol as detected by HPLC) is powdered and passed through 50 meshes, and 1000g is refluxed with 90% ethanol aqueous solution 6000g, 5000g and 4000g successively Extraction, the extraction temperature is 60°C, and the extraction time of each reflux is 2h, 1h, 1h;

[0063] The extracts were combined and concentrated to 10% of their volume, 300g of silica gel powder was added, and the concentration was continued until it became a fluid dry powder, about 600g.

[0064] Take a glass column with a volume of about 3000ml, add 200g of silica gel powder for wet packing, that is, mix silica gel powder with petroleum ether with a boiling point of 60-90°C and then wet pack it into the column until there are no bubbles, then add fluid dry powder for about 600g, finally add PE (petroleum ether 60-90°C) and ETOH (absolute ...

Embodiment 3

[0083] A method for separating magnolobisphenols, comprising the following steps:

[0084] Extraction: Magnolia officinalis root bark (the content of magnolol and honokiol in it is detected by HPLC) is powdered and passed through 40 meshes, and 1000g is taken to carry out reflux extraction with 92% ethanol aqueous solution 6000g, 5000g and 4000g successively , the extraction temperature is 50°C, and the extraction time for each reflux is 2h, 1h, and 1h in sequence;

[0085] The extracts were combined and concentrated to 8% of its volume, added with 300 g of silica gel powder, and continued to concentrate until it became a fluid dry powder.

[0086] Take a glass column with a volume of about 3000ml, add 200g of silica gel powder for wet packing, that is, mix silica gel powder with petroleum ether with a boiling point of 60-90°C and then wet pack it into the column until there are no bubbles, then add fluid dry powder for about 600g, finally add PE (petroleum ether 60-90°C) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com