A kind of madecassoside liposome modified by peg-pcl-peg triblock copolymer and its application

A technology of madecassoside and triblock, which is applied in the field of pharmaceutical preparations, skin care products and daily chemicals, which can solve the problems of drug efficacy and application limitations, and achieve the convenience of skin drug delivery, promotion of healing, and improvement of bioavailability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Weigh 5.05g MPEG and 10.96gε-CL(n (MPEG) :n (ε-CL) 1:10) and round bottom flask, add 0.08g stannous octoate (Sn(Oct) 2 ) After reacting at 120°C for 12h, add 1.66g HMDI (n (ε-CL) :n (HMDI) The ratio is 10:1) at 80°C for 6h. After purification, the PEG-PCL-PEG triblock polymer (PECE) was obtained, which was vacuum-dried to constant weight for use.

[0054] (2) Weigh 0.50g of PECE, 0.50g of egg yolk lecithin, 0.10g of cholesterol, V E Dissolve 0.05 mL of acetate in 10 mL of dichloromethane to make an organic phase solution;

[0055] (3) Dissolve 20 mg / mL madecassoside solution in the organic phase solution prepared in step (2), and then stir at 500 r / min for 5 min to form a W / O emulsion;

[0056] (4) Transfer the W / O emulsion in step (3) to an eggplant-shaped bottle, and remove the organic solvent by evaporating under reduced pressure with a rotary evaporator; then put the eggplant-shaped bottle into a vacuum drying oven to dry, and remove the remaining After ul...

Embodiment 2

[0058] (1) Weigh 5.05g MPEG and 10.96gε-CL(n (MPEG) :n (ε-CL) 1:10) and round bottom flask, add 0.08g stannous octoate (Sn(Oct) 2 ) After reacting at 120°C for 12h, add 1.66g HMDI (n (ε-CL) :n (HMDI) The ratio of 10:1) was reacted at 80°C for 6h, after purification, it was vacuum-dried to constant weight for later use.

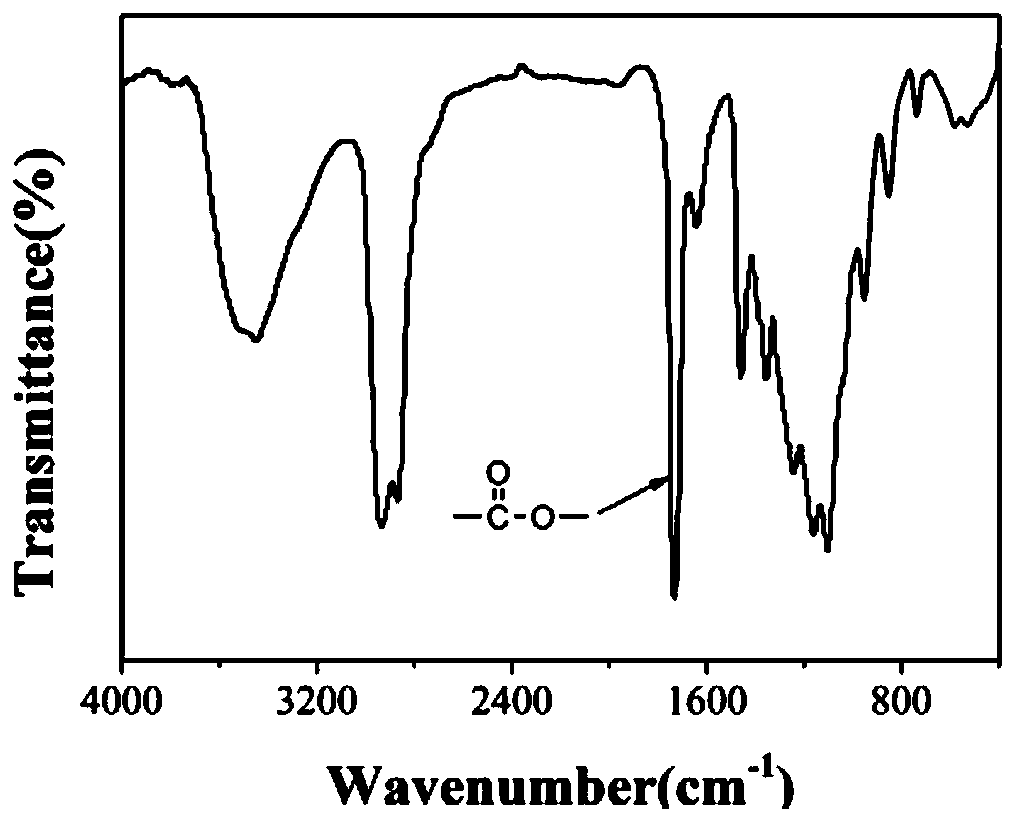

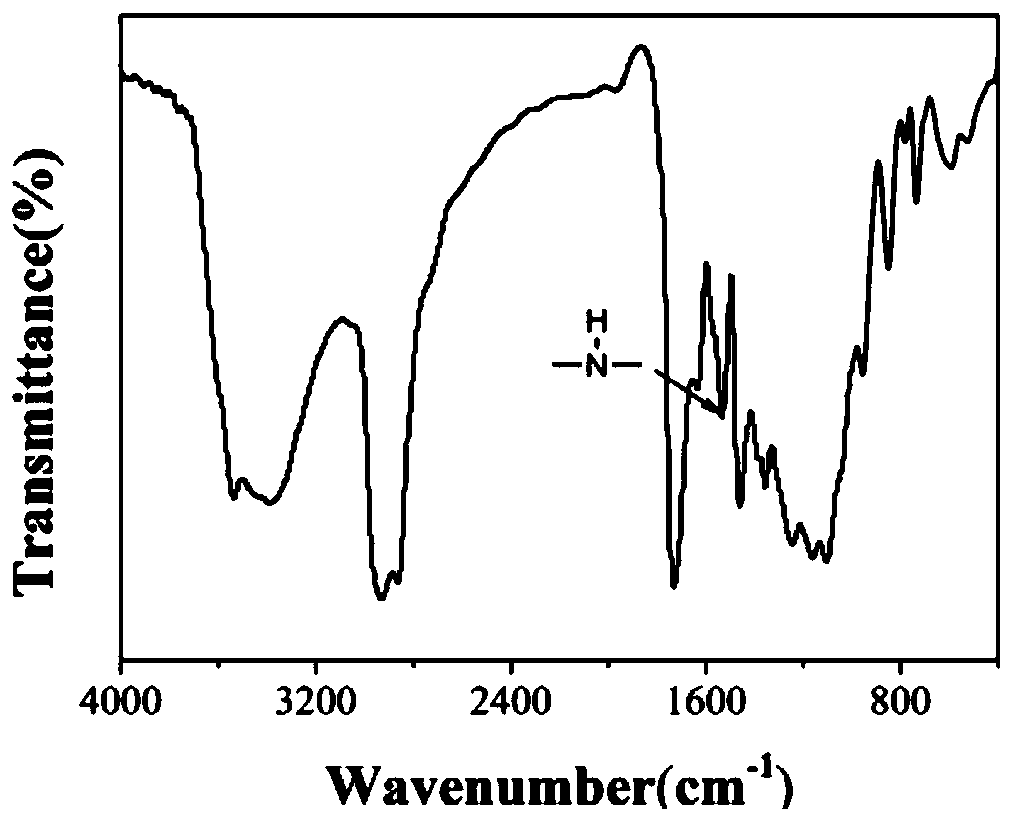

[0059] The first step reaction product PEG-PCL and the second step reaction product PEG-PCL-PEG were characterized by infrared spectroscopy. The result is as figure 1 with 2 shown, from figure 1 It can be seen from the figure that there is a strong carbonyl absorption peak in the 1700-1750 band, which means that the reaction between ε-CL and MPEG forms an ester bond; from figure 2 It can be seen that there is no absorption peak between 2250 and 2270, indicating that HMDI is fully involved in the reaction to form PEG-PCL-PEG, and the characteristic absorption peak of the amide bond appears, which further proves the synthesis of PEG-PCL-PEG .

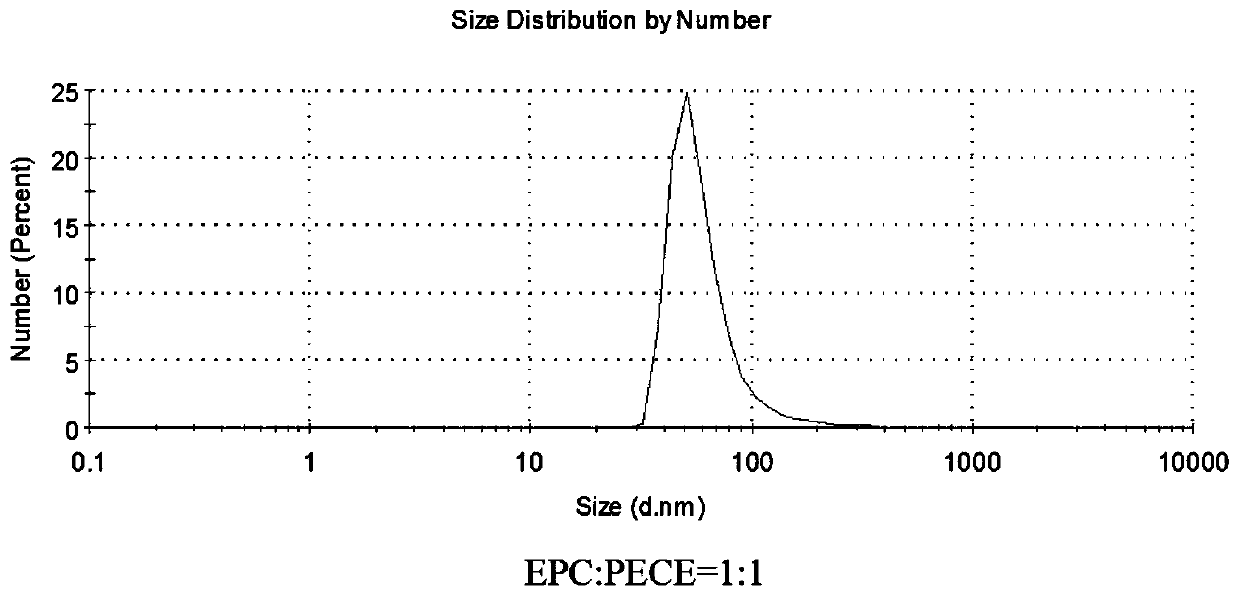

[0060] ...

Embodiment 3

[0069] (1) Weigh 2.14g MPEG and 6.67gε-CL(n (MPEG) :n (ε-CL) 1:15) and round bottom flask, add 0.05g stannous octoate (Sn(Oct) 2 ) After reacting at 100°C for 15h, add 0.65g HMDI (n (ε-CL) :n (HMDI) The ratio of 15:1) was reacted at 50°C for 9h, after purification, it was vacuum-dried to constant weight for later use.

[0070] (2) Weigh 0.40g of PECE, 0.50g of hydrogenated soybean lecithin (HSPC), 0.10g of cholesterol, and 0.05mL of BHA and dissolve them in 10mL of chloroform to make an organic phase solution;

[0071] (3) Dissolve 160mg / mL MA solution in the organic phase solution prepared in step (2), and then stir at 800r / min for 3min to form a W / O emulsion; then add the above W / O emulsion to 160mg / mL MA In the aqueous solution, stir for the second time at 800r / min for 3min to form W / O / W double emulsion;

[0072] (4) Transfer the W / O / W double emulsion in step (3) to an eggplant-shaped bottle, and remove the organic solvent by evaporating under reduced pressure with a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com