A kind of ceramic membrane coating method

A ceramic membrane and ceramic technology, which is applied in the field of ceramic membrane separation, can solve the problems of uneven coating of transition layer and filter layer, high equipment requirements, and low paint utilization rate, so as to reduce artificial individual differences, simple coating device, The effect of short coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

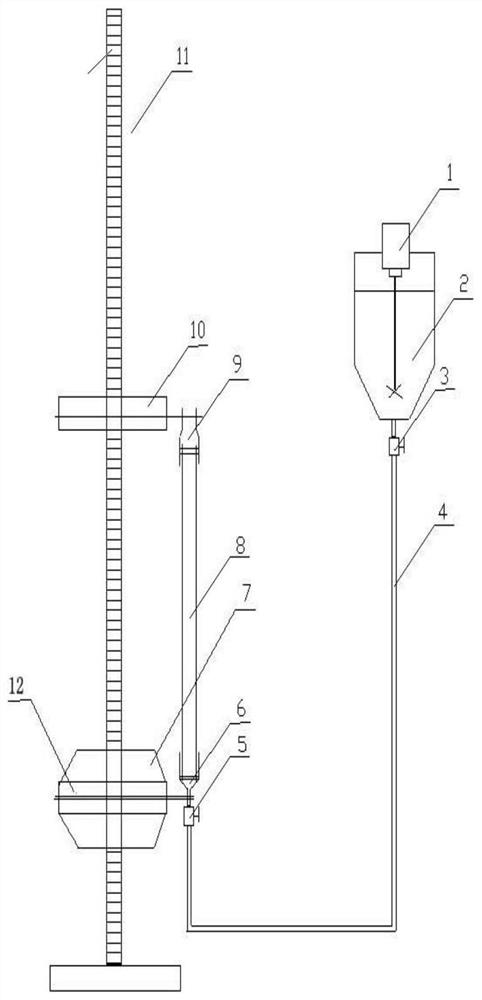

[0025] First prepare a special device for installing the ceramic support body, as attached figure 1 As shown, the special device includes a slurry tank 2, a valve, and a sealing joint, wherein the slurry tank 2 is connected to the lower sealing joint 6 through a hose 4; corresponding to the lower sealing joint 6, there is another one corresponding to the upper sealing joint in the vertical direction. The sealing joint 9; the lower sealing joint 6 and the upper sealing joint 9 are installed on the lifting and fixing column 11, and the upper sealing joint 9 is connected to the lifting and fixing column 11 through the upper sealing joint fixing rod 10; the lower sealing joint 6 is connected to the lifting and fixing column 11 through the lower sealing joint fixing rod 12 is connected to the lifting and fixing column 11; there is a lifting motor 7 on the lifting and fixing column 11, and is located below the upper sealing joint fixing rod 10; the electric agitator 1 is arranged in ...

Embodiment 2

[0028]Mix 10-100 μm silicon carbide with sintering aids, binders and solvents according to the mass percentage of 15wt%: 4.5wt%: 0.5wt%: 80wt%, the sum of the mass percentages of each component is 100%; sintering aids, particles The diameter ranges from 10 to 100 μm; the binder is composed of one or more of polyvinyl alcohol, methyl cellulose, carboxymethyl cellulose, hydroxypropyl methyl cellulose, and hydroxyethyl cellulose; the solvent water A mixture formed with ethanol; mechanically stirred and mixed evenly and ball milled for 3-6 hours to obtain a slurry with good castability; install the two ends of the first ceramic support on the lower sealing joint 6 and the upper sealing joint 9 respectively; the prepared A good coating solution is added to the slurry tank 2. Under the action of the electric agitator 1, the slurry is mixed more evenly. Open the A valve, let the slurry flow to the B valve 5 through the hose 4, and ensure that the B valve 5 Higher than the liquid leve...

Embodiment 3

[0030] Mix 0.02-10 μm silicon carbide with sintering aids, binders, dispersants and solvents according to the mass percentage of 25wt%: 6wt%: 3wt%: 3wt%: 63wt%; the particle size range of sintering aids is 0.02-10 μm; The binder is the same as the solvent in Example 1; the dispersant is composed of one or more of sodium hexametaphosphate, sodium citrate, polyacrylic acid, triethanolamine, and polymethacrylic acid amine; mechanically agitate and mix uniformly and ball mill for 6- 12h, obtain the slurry with good castability;

[0031] Install the two ends of the first ceramic support on the lower sealing joint 6 and the upper sealing joint 9 respectively, and then add the prepared slurry into the slurry tank 2. Under the action of the electric stirrer 1, the slurry mixing is more efficient. Evenly, open A valve 3, let the slurry flow to B valve 5 through the hose 4, and ensure that B valve 5 is higher than the slurry liquid level in the slurry tank 2, then open B valve 5, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com