High-temperature-resistant modified road asphalt

A technology of road asphalt and high temperature resistance, which is applied to building insulation materials, building components, buildings, etc. It can solve the problems of low dynamic viscosity, poor resistance to temperature fatigue and load fatigue, and easy rutting, so as to achieve high temperature resistance. High dynamic viscosity and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

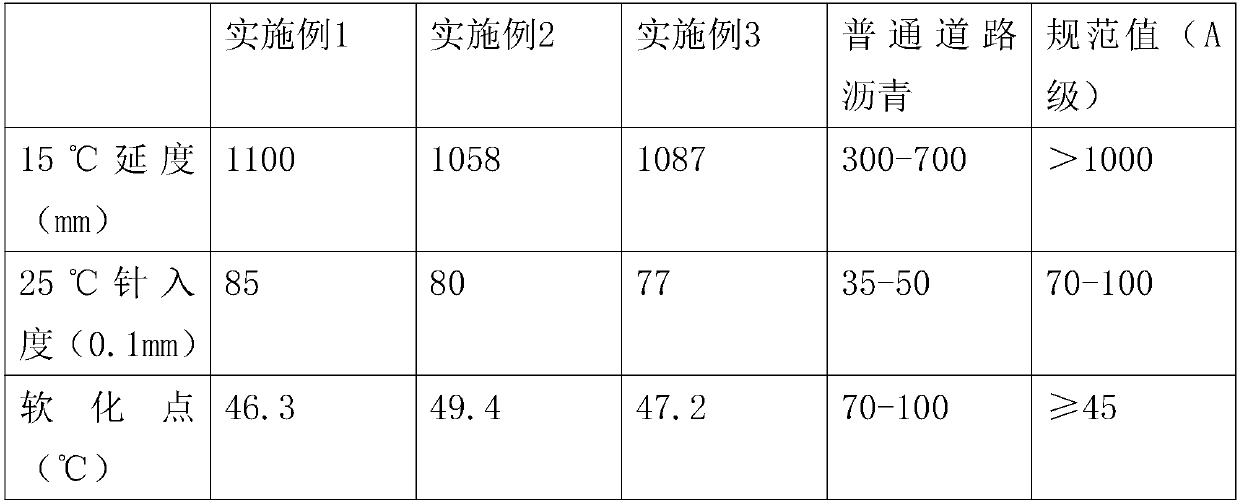

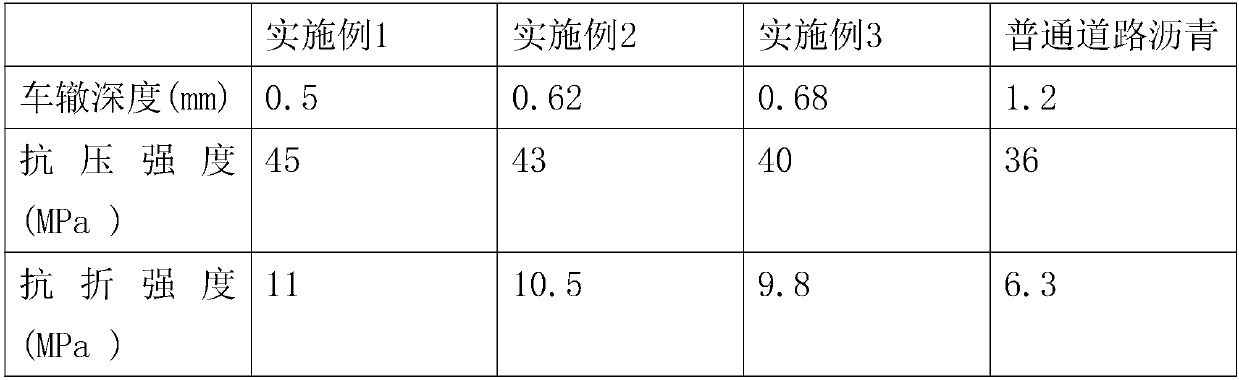

Examples

Embodiment 1

[0014] A high-temperature-resistant modified road asphalt, which is composed of the following raw materials in parts by weight: 100 parts of base asphalt, 15 parts of perfluoroether rubber, 15 parts of hydrogenated nitrile rubber, 8 parts of borosilicate rubber, and 6 parts of SBS thermoplastic elastomer , 12 parts of furfural, 18 parts of composite resin, 3 parts of asbestos powder, 0.5 part of zinc oxide, 5 parts of xylene, 3 parts of zinc naphthenate, 3 parts of barium petroleum sulfonate, 8 parts of kerosene, 0.6 part of lauroyl diethanolamine, 2 parts of silicon nitride, 0.18 parts of chromium carbide, 1.5 parts of aluminized glass microspheres, 6 parts of calcium sulfate whisker powder, 7 parts of chlorinated paraffin, and 3 parts of additives.

[0015] Wherein, the auxiliary agent is composed of the following raw materials in weight percentage: 50% kaolin, 4% tung oil, 5% ammonium polyphosphate, 8% calcium lignosulfonate, 5% calcium oxide, 10% trichloroethyl phosphate, ...

Embodiment 2

[0018] A high-temperature-resistant modified road asphalt, which is composed of the following raw materials in parts by weight: 90 parts of base asphalt, 18 parts of perfluoroether rubber, 12 parts of hydrogenated nitrile rubber, 9 parts of borosilicate rubber, and 7 parts of SBS thermoplastic elastomer , 10 parts of furfural, 18 parts of composite resin, 2 parts of asbestos powder, 0.5 parts of zinc oxide, 6 parts of xylene, 3 parts of zinc naphthenate, 2 parts of barium petroleum sulfonate, 8 parts of kerosene, 0.6 part of lauroyl diethanolamine, 3 parts of silicon nitride, 0.2 parts of chromium carbide, 2 parts of aluminized glass beads, 5 parts of calcium sulfate whisker powder, 7 parts of chlorinated paraffin, 3 parts of additives.

[0019] Wherein, the auxiliary agent is composed of the following raw materials in weight percentage: 50% kaolin, 4% tung oil, 5% ammonium polyphosphate, 8% calcium lignosulfonate, 5% calcium oxide, 10% trichloroethyl phosphate, Magnesium powd...

Embodiment 3

[0022] A high-temperature-resistant modified road asphalt, which is composed of the following raw materials in parts by weight: 100 parts of base asphalt, 16 parts of perfluoroether rubber, 12 parts of hydrogenated nitrile rubber, 9 parts of borosilicate rubber, and 6 parts of SBS thermoplastic elastomer , 11 parts of furfural, 17 parts of composite resin, 4 parts of asbestos powder, 1 part of zinc oxide, 7 parts of xylene, 3 parts of zinc naphthenate, 3 parts of barium petroleum sulfonate, 6 parts of kerosene, 0.8 parts of lauroyl diethanolamine, 2 parts of silicon nitride, 0.1 part of chromium carbide, 1 part of aluminized glass beads, 7 parts of calcium sulfate whisker powder, 7 parts of chlorinated paraffin, and 3 parts of additives.

[0023] Wherein, the auxiliary agent is composed of the following raw materials in weight percentage: 50% kaolin, 4% tung oil, 5% ammonium polyphosphate, 8% calcium lignosulfonate, 5% calcium oxide, 10% trichloroethyl phosphate, Magnesium pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com