Special-purpose organic-inorganic ecological fertilizer for alleviating root rot and seedling death of tea as well as preparation method thereof

An ecological fertilizer and organic fertilizer technology, which is applied in the field of special organic-inorganic ecological fertilizer and its preparation, can solve the problems that affect the tea farmers' enthusiasm for planting and economic income, cannot promote the recovery of diseased plants, and poor tea quality, etc., to improve oxygen deficiency , stable product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

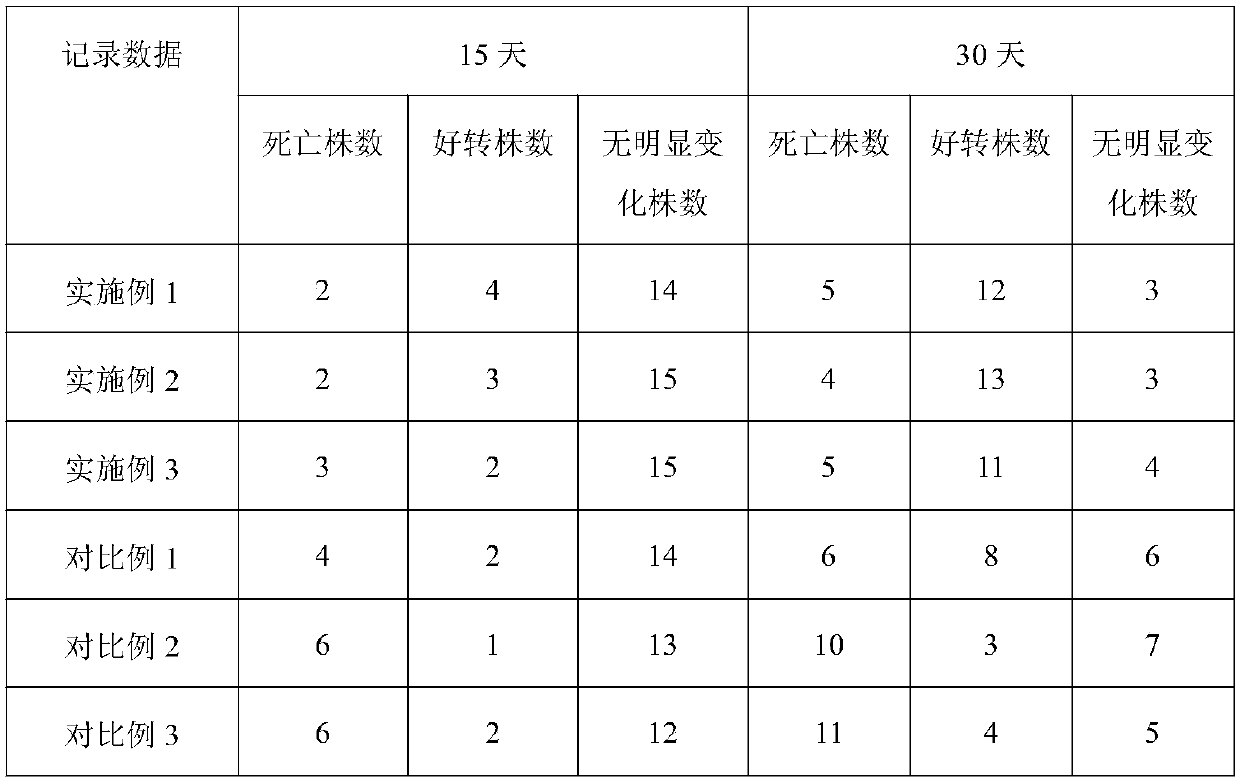

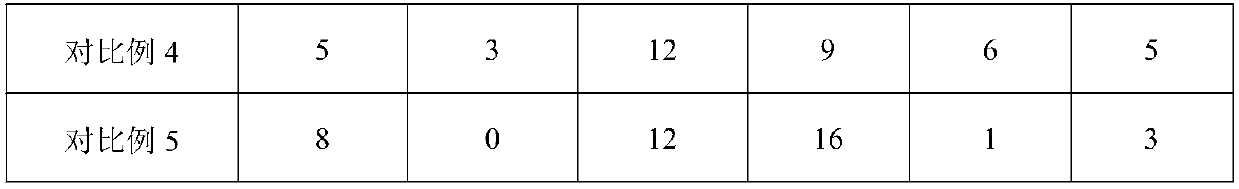

Examples

Embodiment 1

[0029] (1) Organic fertilizer: 70 parts of crop straw, 40 parts of human and animal manure, 8 parts of orange peel and 8 parts of pomegranate peel are pulverized and mixed evenly; aerobic fermentation for 8 days at a temperature of 60°C, followed by anaerobic fermentation for 6 days at a humidity of 43% and a temperature of 50°C; dried, crushed, and sieved organic fertilizers; inorganic fertilizers Fertilizer: It is made by mixing urea, potassium superphosphate, ammonium sulfate, and potassium dihydrogen phosphate according to the ratio of nitrogen, phosphorus, and potassium to 2:1:3; rooting agent: it is composed of indole acetic acid and naphthalene acetic acid; microbial bacteria Fertilizer: It is made by mixing Bacillus lateralosporus, Trichoderma harzianum and lactic acid bacteria according to the ratio of the number of live bacteria to 2:3:5;

[0030] (2) Take 50 parts of organic fertilizer, 28 parts of chicken manure, 18 parts of inorganic fertilizer, 0.3 part of rootin...

Embodiment 2

[0032] (1) Organic fertilizer: 50 parts of crop straw, 50 parts of human and animal manure, 5 parts of orange peel and 5 parts of pomegranate peel are pulverized and mixed evenly; , aerobic fermentation for 5 days at a temperature of 65°C, followed by anaerobic fermentation for 10 days at a humidity of 45% and a temperature of 55°C; dried, crushed and sieved organic fertilizers; inorganic fertilizers Fertilizer: Potassium superphosphate, ammonium sulfate, and potassium dihydrogen phosphate are mixed according to the amount of nitrogen, phosphorus, and potassium in a ratio of 2:1:2; rooting agent: indole butyric acid; microbial fertilizer: composed of lateral sporophytes Bacillus, Trichoderma harzianum and lactic acid bacteria are mixed according to the ratio of the number of live bacteria to 2:3:4;

[0033] (2) Take 40 parts of organic fertilizer, 35 parts of chicken manure, 10 parts of inorganic fertilizer, 0.5 part of rooting agent, 3 parts of humic acid, and 5 parts of micr...

Embodiment 3

[0035] (1) Organic fertilizer: 80 parts of crop straw, 30 parts of human and animal manure, 10 parts of orange peel and 10 parts of pomegranate peel are pulverized and mixed evenly; aerobic fermentation for 10 days at a temperature of 55°C, followed by anaerobic fermentation for 5 days at a humidity of 40% and a temperature of 45°C; organic fertilizers made by drying, crushing and sieving fermented raw materials; inorganic Fertilizer: It is made by mixing urea, potassium superphosphate, ammonium sulfate, and potassium dihydrogen phosphate according to the ratio of nitrogen, phosphorus, and potassium as 2:1:4; Rooting agent: It is made by mixing naphthaleneacetic acid and sodium nitrophenolate ; Microbial fertilizer: the ratio of the number of live bacteria of Bacillus lateralis, Trichoderma harzianum, and lactic acid bacteria is 3:3:5;

[0036] (2) Take 70 parts of organic fertilizer, 20 parts of chicken manure, 25 parts of inorganic fertilizer, 0.1 part of rooting agent, 5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com