Biological organic fertilizer zymocyte for fermenting wastes

A bio-organic fertilizer and waste technology, which is applied in the treatment of bio-organic parts, organic fertilizers, and the preparation of organic fertilizers, can solve environmental pollution and other problems, and achieve the effects of reducing costs, improving the environment, and having strong functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

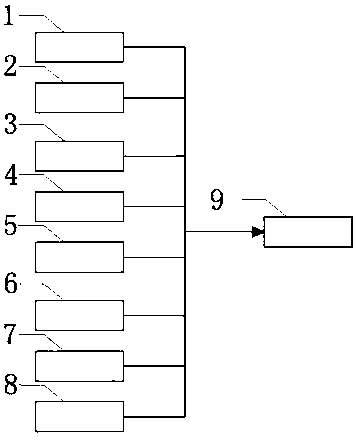

[0027] It can be seen from the content of the invention that a bio-organic fertilizer fermentation bacterium used for waste fermentation treatment consists of Bacillus 1, lactic acid bacteria 2, saccharomyces 3, photosynthetic bacteria 4, actinomycetes 5, nitrogen-fixing bacteria 6, phosphorus-solubilizing bacteria 7 , Potassium-decomposing bacteria 8 and eight kinds of bacteria complete the preparation method by mixing 9; the ratio of its raw materials is Bacillus 1: lactic acid bacteria 2: yeast 3: photosynthetic bacteria 4: actinomycetes 5: nitrogen-fixing bacteria 6: phosphorus-solubilizing bacteria 7 ︰Potassium decomposing bacteria 8=12~18︰20~28︰20~30︰10~18︰10~15︰8~15︰12~22︰10~15;

[0028] Mixing 9: mix each raw material according to the above ratio evenly;

[0029] The Bacillus 1 uses LB medium, 1L distilled water, 20g glucose, 15g peptone, 5g sodium chloride, 0.5g beef extract, 20g agar; the inoculum size is 5%-10%, cultured under aerobic conditions at 30-37°C 1-2 days...

Embodiment 2

[0048] Dosage:

[0049] Fermented livestock and poultry manure: 1. Separate the solid and liquid of the livestock and poultry manure or dry it naturally until the water content reaches about 50-60% (it is best to hold it in a ball and loose it on the ground).

[0050] 2. Add 1 kg of this product to every ton of livestock and poultry manure, stir evenly, pile up to 1 meter high and 2 meters wide for fermentation, or add 1 kg of this product to 10 kg of water, 100 grams of sugar, and soak for 3-6 hours After adding bran and bran, mix well and ferment, the effect is more obvious.

[0051] 3. When the ambient temperature is low (generally below 10°C), cover it with a plastic film to accelerate the early heating.

[0052] 4. The internal temperature is controlled at around 70°C. If the temperature is too high, it will affect the nutrients. The moisture should be controlled at 60-65%. During the fermentation process, pay attention to oxygen supply and turning.

[0053] 5. Properly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com