PCL-PLGA slow-release preparation and preparation method thereof

A technology of PCL-PLGA and sustained-release preparations, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve the problems of restricting the development of PLGA, poor mechanical toughness, and too short degradation cycle, etc. problems, achieve the effects of low cost, easy operation, and simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

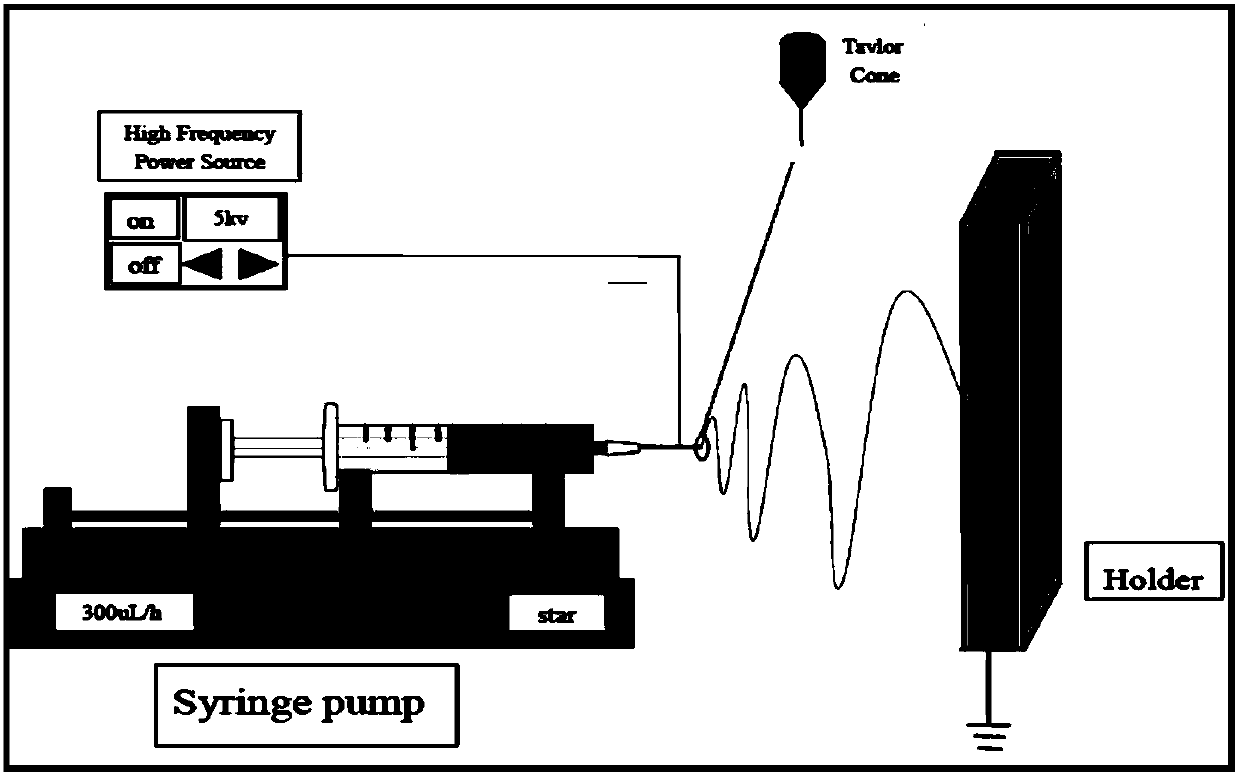

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of spinning solution:

[0031] In parts by volume, 9 parts of trifluoroethanol and 1 part of distilled water are mixed to prepare a spinning solvent; the PCL-PLGA polymer is added to the above spinning solvent and the concentration of the PCL-PLGA polymer in the spinning solvent is 10wt%; stirring at 25-30°C for 12 hours to fully dissolve the PCL-PLGA polymer; standing for defoaming for 2 hours to obtain a PCL-PLGA electrospinning solution;

[0032] Among them, in the PCL-PLGA polymer, the molecular weight of PCL is 8×10 4 Da, the molecular weight of PLGA is 5×10 4 Da;

[0033] Synthetic method: using stannous chloride (0.5%) as a catalyst, racemic lactic acid (dl-PLGA) and PCL are fed at a ratio of 1:1 to 1:2 (molar ratio), and dl-PLGA and PCL are mixed at 180 ℃, 70Pa under direct melt copolymerization for 12 hours, can obtain intrinsic viscosity poly(caprolactone-lactic acid glycolic acid), that is, the PCL-PLGA polymer of the present invention, its ...

Embodiment 2

[0037] 1) Preparation of spinning solution:

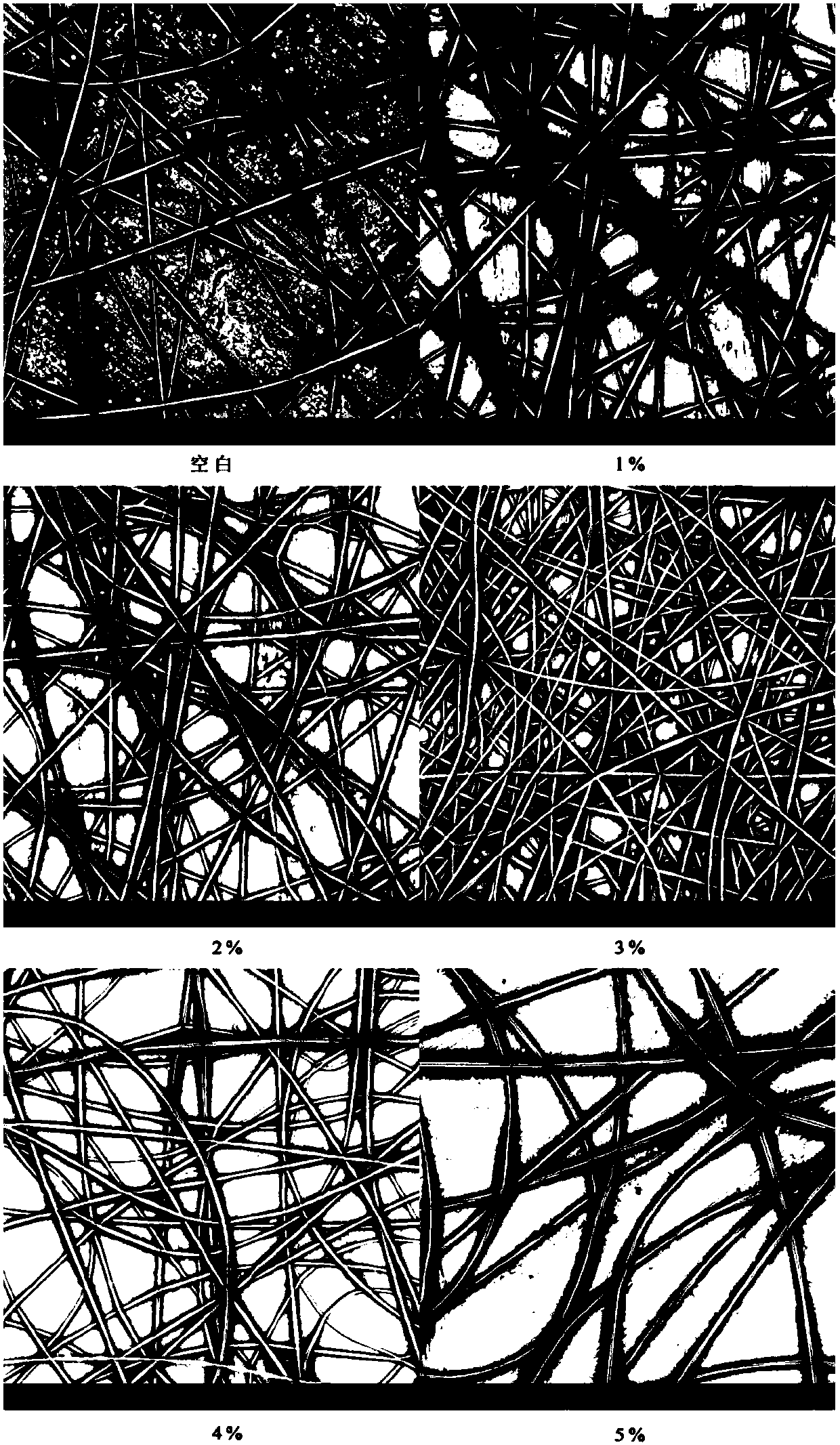

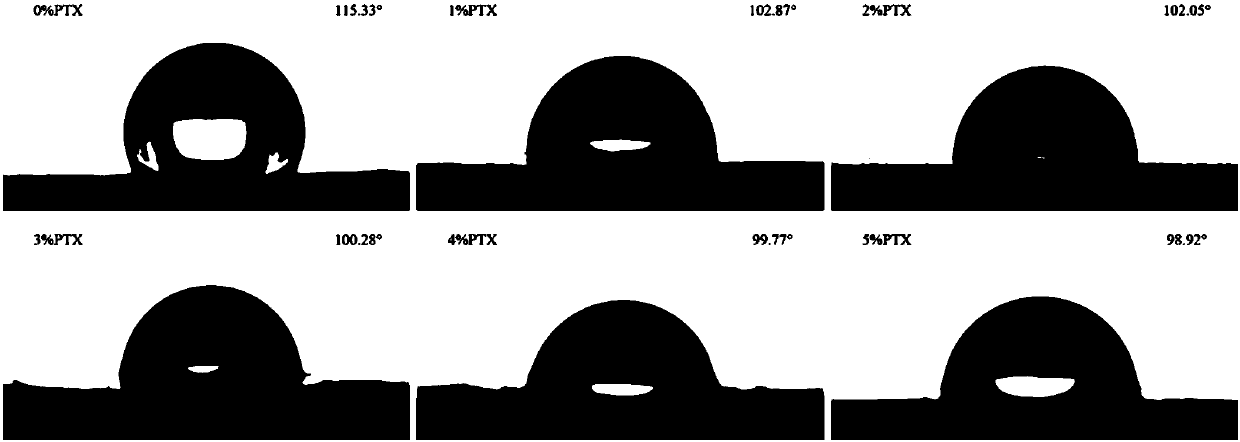

[0038]In parts by volume, 9 parts of trifluoroethanol and 1 part of distilled water are mixed to prepare a spinning solvent; the mixture of PCL-PLGA polymer and paclitaxel is added to the above spinning solvent and the concentration of the mixture in the spinning solvent is 10wt%; stirring at 25-30°C for 12 hours to fully dissolve the mixture; standing for defoaming for 2 hours to obtain a PCL-PLGA electrospinning solution;

[0039] Wherein, in the mixture, the amount of paclitaxel is 1wt% of the amount of the mixture; in the PCL-PLGA polymer, the molecular weight of PCL is 8×10 4 Da, the molecular weight of PLGA is 5×10 4 Da; synthetic method is the same as in Example 1, below.

[0040] 2) Preparation of nanofibers:

[0041] The PCL-PLGA electrospinning solution obtained in step 1) was subjected to electrospinning at a humidity of 30-50% and a temperature of 25-30°C. The spinning voltage was 8kV, and the flow rate of the spinni...

Embodiment 3

[0043] 1) Preparation of spinning solution:

[0044] In parts by volume, 9 parts of trifluoroethanol and 1 part of distilled water are mixed to prepare a spinning solvent; the mixture of PCL-PLGA polymer and paclitaxel is added to the above spinning solvent and the concentration of the mixture in the spinning solvent is 10wt%; stirring at 25-30°C for 12 hours to fully dissolve the mixture; standing for defoaming for 2 hours to obtain a PCL-PLGA electrospinning solution;

[0045] Wherein, in the mixture, the amount of paclitaxel is 2wt% of the amount of the mixture; in the PCL-PLGA polymer, the molecular weight of PCL is 8×10 4 Da, the molecular weight of PLGA is 5×10 4 Da;

[0046] 2) Preparation of nanofibers:

[0047] The PCL-PLGA electrospinning solution obtained in step 1) was subjected to electrospinning at a humidity of 30-50% and a temperature of 25-30°C. The spinning voltage was 8kV, and the flow rate of the spinning solution was 800 μL / h. The horizontal distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com