Polyolefin lithium battery diaphragm and preparation method thereof

A polyolefin diaphragm and polyolefin technology, applied in the direction of lithium batteries, circuits, electrical components, etc., can solve the problems of low electronic isolation ability of the diaphragm, unresolved self-discharge and strength of the electrospun film, and the influence of the pore structure. Good high temperature integrity, improved thermal safety, improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

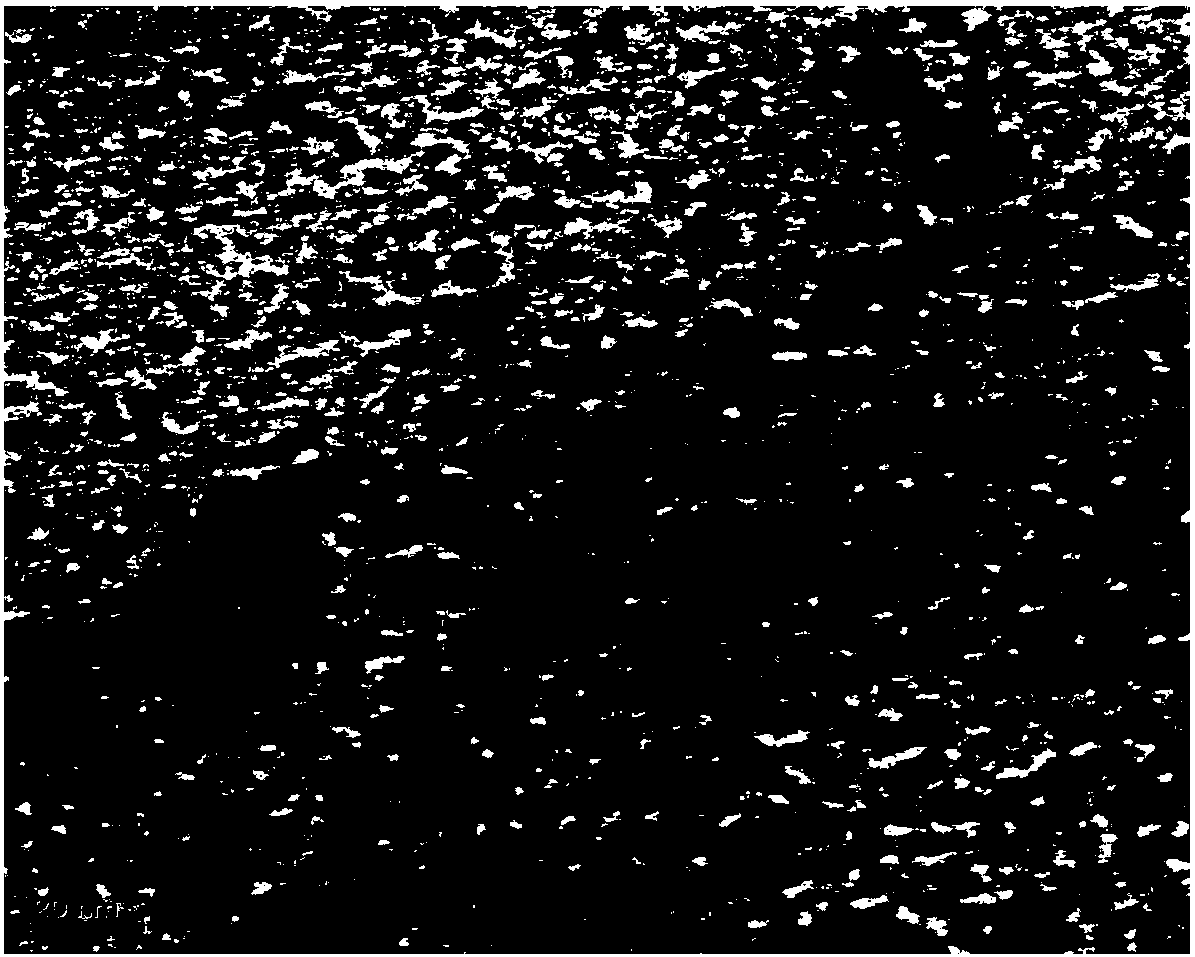

[0037] A polyolefin lithium battery diaphragm, with a dry-process single-drawn polypropylene lithium battery diaphragm (20 μm, porosity 42vol%) as a substrate, and modified polyethylene terephthalate is electrospun on both sides of the polyolefin diaphragm (PET) fiber coating, the thickness of the modified polyethylene terephthalate (PET) fiber coating is 2 μ m; The described modified polyethylene terephthalate (PET) fiber is A composite fiber of silica nanoparticles and polyethylene terephthalate.

[0038] The preparation method of the above polyolefin lithium battery diaphragm, the specific steps are as follows:

[0039] 1) Disperse terephthalic acid and tetraethyl orthosilicate in ethylene glycol and stir for 0.5h. The weight ratio of terephthalic acid, tetraethyl orthosilicate and ethylene glycol is 1:0.05:2; then, in Under stirring state, continue to slowly add nitric acid aqueous solution with a concentration of 10wt% as a hydrolysis catalyst, control the adding speed t...

Embodiment 2

[0048] A polyolefin lithium battery separator, the dry-process double-stretched polypropylene lithium battery separator (50 μm, porosity 39vol%) is used as a substrate, and modified polyethylene terephthalate is electrospun on both sides of the polyolefin separator (PET) fiber coating, the thickness of the modified polyethylene terephthalate (PET) fiber coating is 5 μ m; The described modified polyethylene terephthalate (PET) fiber is A composite fiber of silica nanoparticles and polyethylene terephthalate.

[0049] The preparation method of the above polyolefin lithium battery diaphragm, the specific steps are as follows:

[0050] 1) Disperse terephthalic acid and tetraethoxysilane in ethylene glycol and stir for 1 hour. The weight ratio of terephthalic acid, tetraethoxysilane and ethylene glycol is 1:0.01:3; then, stir Continue to slowly add a hydrochloric acid aqueous solution with a concentration of 20wt% as a hydrolysis catalyst, control the addition rate so that the pH ...

Embodiment 3

[0057] A polyolefin lithium battery separator, with wet-process polyethylene lithium battery separator (12 μm, 46vol%) as the substrate, one side of the polyolefin separator is electrospun with modified polyethylene terephthalate (PET) fibers Coating, the thickness of the modified polyethylene terephthalate (PET) fiber coating is 10 μ m; The described modified polyethylene terephthalate (PET) fiber is titanium dioxide nanoparticle and A composite fiber made of polyethylene terephthalate.

[0058] The preparation method of the above polyolefin lithium battery diaphragm, the specific steps are as follows:

[0059] 1) Disperse terephthalic acid and ethyl titanate in ethylene glycol and stir for 2 hours. The weight ratio of terephthalic acid, ethyl titanate and ethylene glycol is 1:0.1:5; then, under stirring Continue to slowly add hydrochloric acid aqueous solution with a concentration of 30wt% as a hydrolysis catalyst, control the adding speed to keep the pH of the solution sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com