Chitosan microspheres as well as preparation method and application thereof to reduction of dielectric loss of mineral oil

A technology of chitosan microspheres and chitosan, which is applied in its preparation, chitosan microspheres, and the application field of reducing the dielectric loss of mineral oil, can solve the problems of reducing chelation, electric neutralization and adsorption bridging, It is difficult to separate the adsorbent from the oil, reducing the contact area of the oil, etc., to achieve the effect of stable structure, convenient operation and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

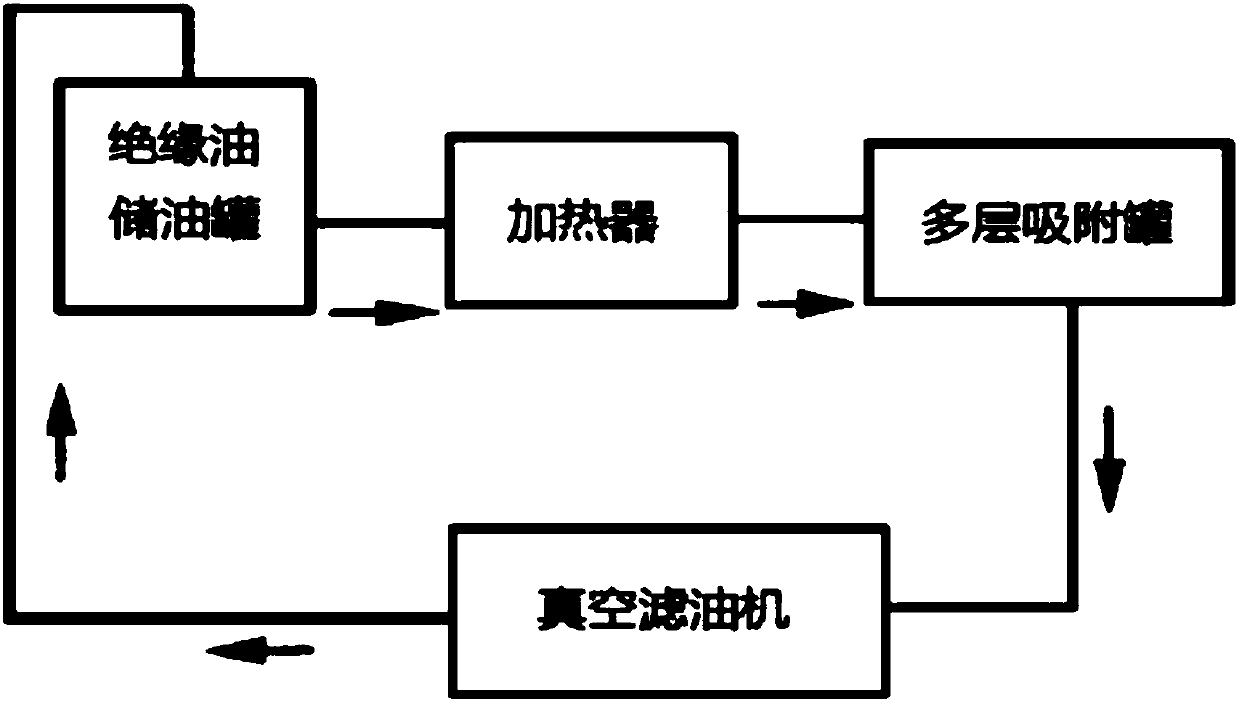

Method used

Image

Examples

preparation example Construction

[0033] The present embodiment provides a kind of preparation method of chitosan microsphere, comprises the following steps:

[0034]S1, dissolving chitosan in an acid and spraying it into an aqueous solution of sodium polyphosphate for cross-linking reaction to obtain preliminary cross-linked chitosan microspheres; wherein the acid is preferably acetic acid, and the acetic acid is preferably configured so that the mass concentration is 1%. ~5% aqueous solution is used; the viscosity of chitosan is preferably 0.25 ~ 0.65 Pa s; more preferably, chitosan is dissolved in acid to form a solution with a mass concentration of 0.5 ~ 3%, and then sprayed to a mass fraction of 1 ~ 5% % sodium polyphosphate aqueous solution for cross-linking reaction; further preferably use the nozzle of the electrospinning machine to spray the chitosan solution into the sodium polyphosphate aqueous solution.

[0035] S2. Wash the preliminary crosslinked chitosan microspheres with water, filter and drain...

Embodiment 1

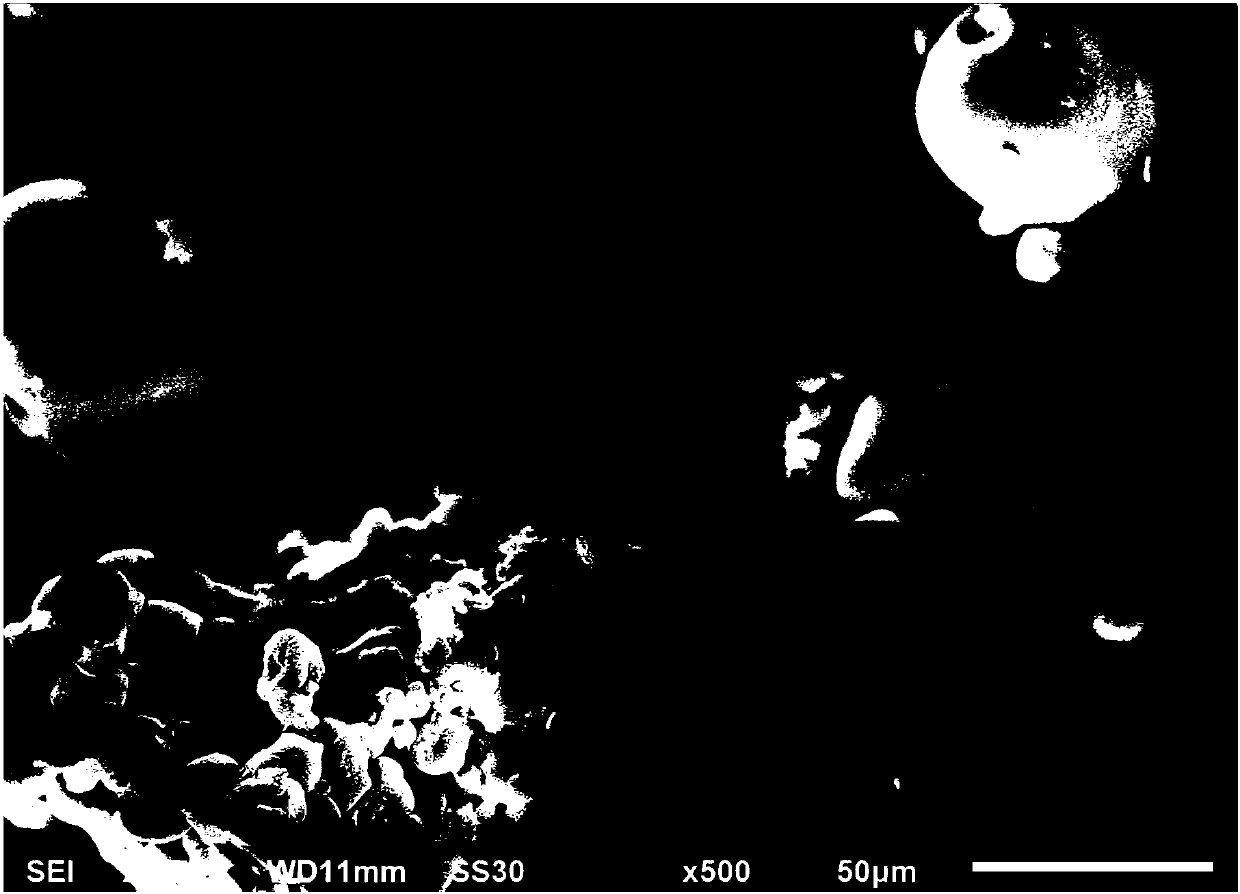

[0042] The present embodiment provides a kind of chitosan microsphere, and its specific preparation method is as follows:

[0043] S101, the preparation mass fraction is the chitosan solution of 0.5%; Dissolving the chitosan solution in the acetic acid solution that the mass fraction is 2% is prepared into the chitosan solution that the mass fraction is 0.5%; Wherein the viscosity of chitosan is 0.48Pa·s;

[0044] S102. Disperse the chitosan solution with a mass fraction of 0.5% in an aqueous solution of sodium polyphosphate with a mass fraction of 1% by using the nozzle system of an electrospinning machine, react at 25° C. for 2 hours to carry out a preliminary cross-linking reaction, and initially The cross-linked chitosan microspheres were washed with distilled water, filtered and drained, added to a sodium hydroxide solution with a mass concentration of 5% and stirred, and 15ml of epichlorohydrin was added as a cross-linking agent, and carried out at 25°C for 2h The secon...

Embodiment 2

[0048] The present embodiment provides a kind of chitosan microsphere, and its specific preparation method is as follows:

[0049] S201, preparing a chitosan solution with a mass fraction of 2%; dissolving chitosan in an acetic acid solution with a mass fraction of 3% to prepare a chitosan solution with a mass fraction of 2%; wherein the viscosity of chitosan is 0.54 Pa s;

[0050] S202. Disperse the chitosan solution with a mass fraction of 2% in an aqueous solution of sodium polyphosphate with a mass fraction of 3% by using the nozzle system of an electrospinning machine, react at 25° C. for 3 hours to carry out a preliminary cross-linking reaction, and initially The cross-linked chitosan microspheres were washed with distilled water, filtered and drained, added to a sodium hydroxide solution with a mass concentration of 7%, stirred, and 10ml of epichlorohydrin was added as a cross-linking agent, and carried out at 25°C for 4h The secondary cross-linking reaction, obtains t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com