Preparation method of ternary copolymerized amphoteric polyacrylamide

A technology of ternary copolymerization of amphoteric and polyacrylamide, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc., can solve the problems of poor flocculation effect and slow dissolution rate of fracturing wastewater, and achieve optimal Excellent treatment effect, good adsorption performance, and wide range of applicable pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of the present embodiment ternary copolymerization amphoteric polyacrylamide is prepared according to the following steps:

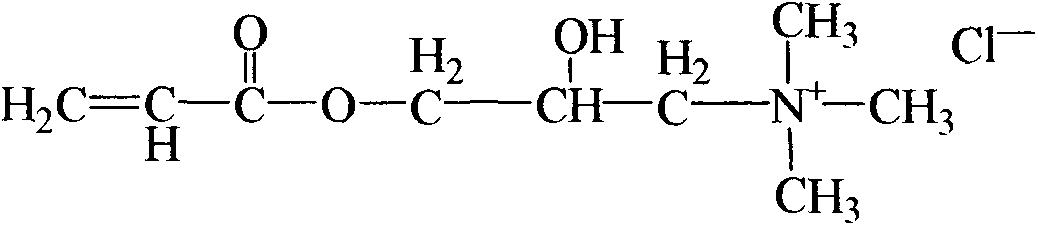

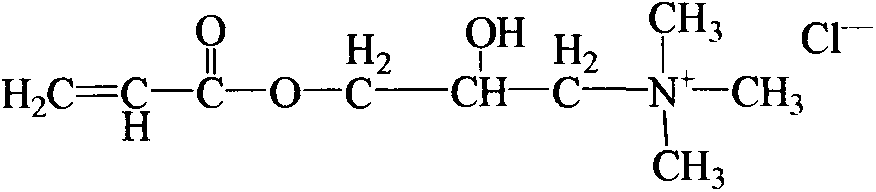

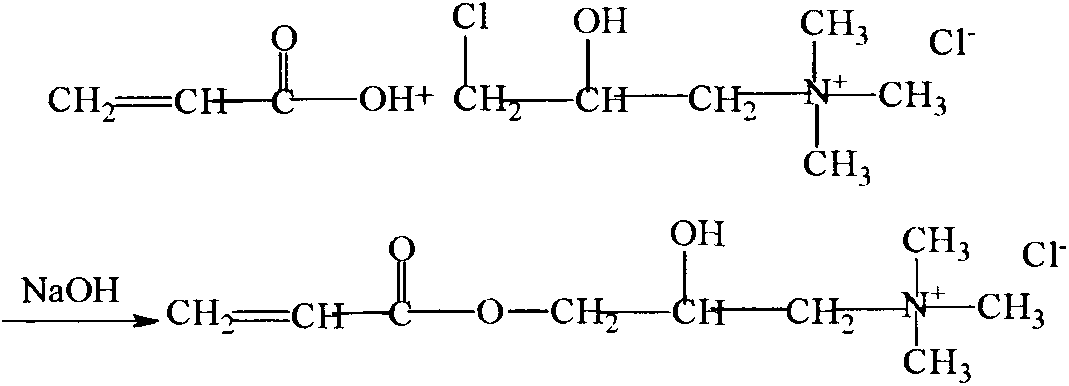

[0039] (1) Preparation of quaternary ammonium salt cationic monomer (AHPTAC):

[0040] Add 15 mL of absolute ethanol and 0.05 mol of acrylic acid (AA) into the three-necked flask, and slowly add 0.05 mol of NaOH saturated aqueous solution dropwise under stirring conditions. After 5 min, 0.065 mol of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC) aqueous solution (60% by mass fraction) was slowly added dropwise. After the dropwise addition, water was added to make the reaction system satisfy V (absolute ethanol): V (water) = 1:1. The temperature was raised to 55°C and the reaction temperature was maintained for 4h. Cool to room temperature after the reaction, and distill under reduced pressure to remove absolute ethanol to obtain crude AHPTAC. Add isopropanol to the obtained AHPTAC crude product to dissolve AHPTAC an...

Embodiment 2

[0046] The steps for preparing terpolymer amphoteric polyacrylamide in this example are the same as those in Example 1 except that the following steps are different:

[0047] (1) Preparation of quaternary ammonium salt cationic monomer (AHPTAC):

[0048] Add 15 mL of acetonitrile and 0.05 mol of acrylic acid (AA) into the three-neck flask, and slowly add 0.05 mol of NaOH saturated aqueous solution dropwise under stirring conditions. After 5 min, 0.055 mol of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC) aqueous solution (60% by mass fraction) was slowly added dropwise. After the dropwise addition, water was added to make the reaction system satisfy V (absolute ethanol): V (water) = 1:1. The temperature was raised to 65°C and the reaction temperature was maintained for 4.5h. Cool down after the reaction, and distill under reduced pressure to remove the solvent to obtain the crude product of AHPTAC. Add absolute ethanol to the obtained AHPTAC crude product to di...

Embodiment 3

[0052] The steps for preparing terpolymer amphoteric polyacrylamide in this example are the same as those in Example 1 except that the following steps are different:

[0053] (1) Preparation of quaternary ammonium salt cationic monomer (AHPTAC):

[0054] Add 15 mL of isopropanol and 0.05 mol of acrylic acid (AA) into the three-neck flask, and slowly add 0.05 mol of NaOH saturated aqueous solution dropwise under stirring conditions. After 5 min, 0.055 mol of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHPTAC) aqueous solution (60% by mass fraction) was slowly added dropwise. After the dropwise addition, water was added to make the reaction system satisfy V (absolute ethanol): V (water) = 1:1. The temperature was raised to 75°C and the reaction temperature was maintained for 6h. Cool down after the reaction, and distill under reduced pressure to remove the solvent to obtain the crude product of AHPTAC. Add absolute ethanol to the obtained AHPTAC crude product to disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com