Porous MOF/CNFs composite material for lithium cathode protection

A composite material and metal lithium technology, applied in the field of lithium-ion batteries, can solve the problems of increased process complexity, low strength, and difficult production, to improve cycle stability and safety, reduce current density, and good chemical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

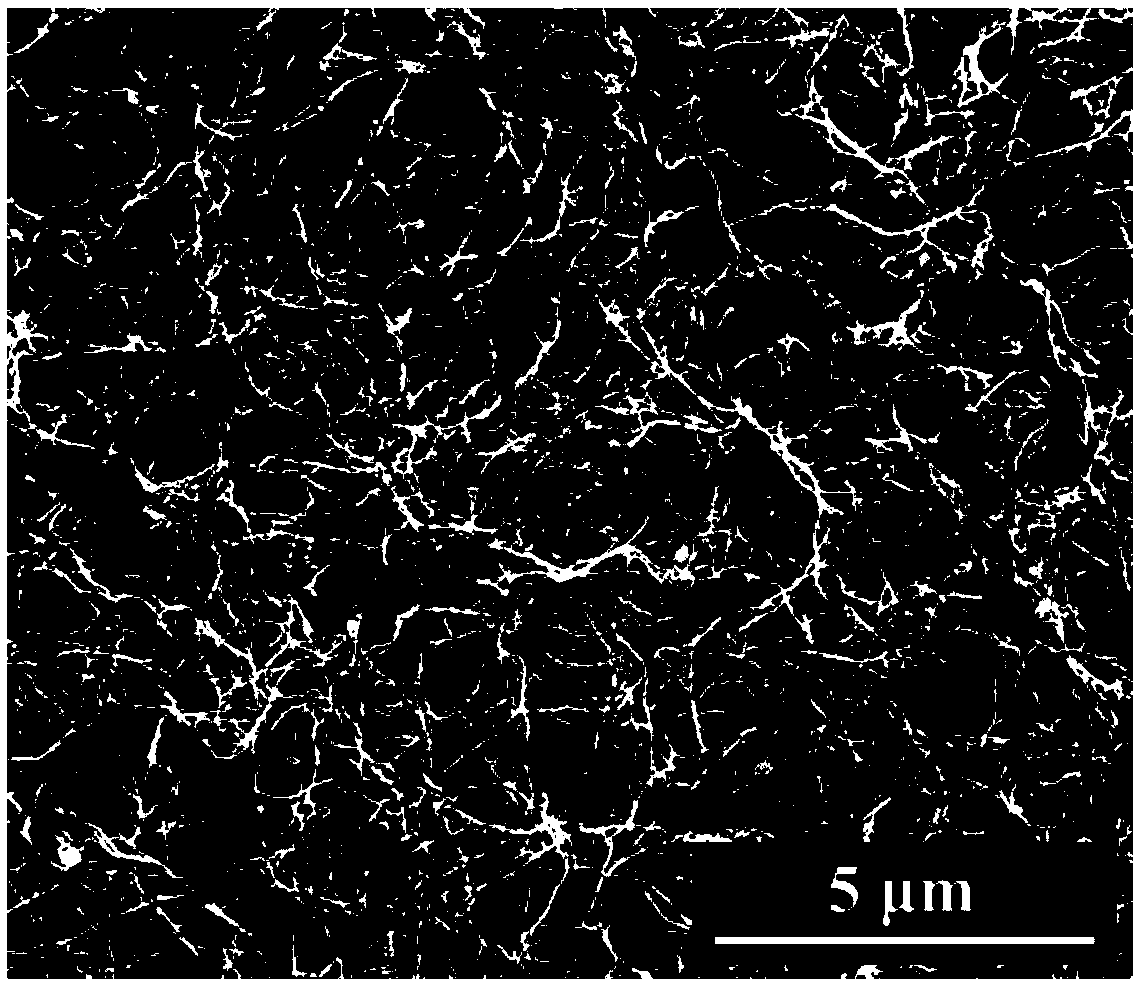

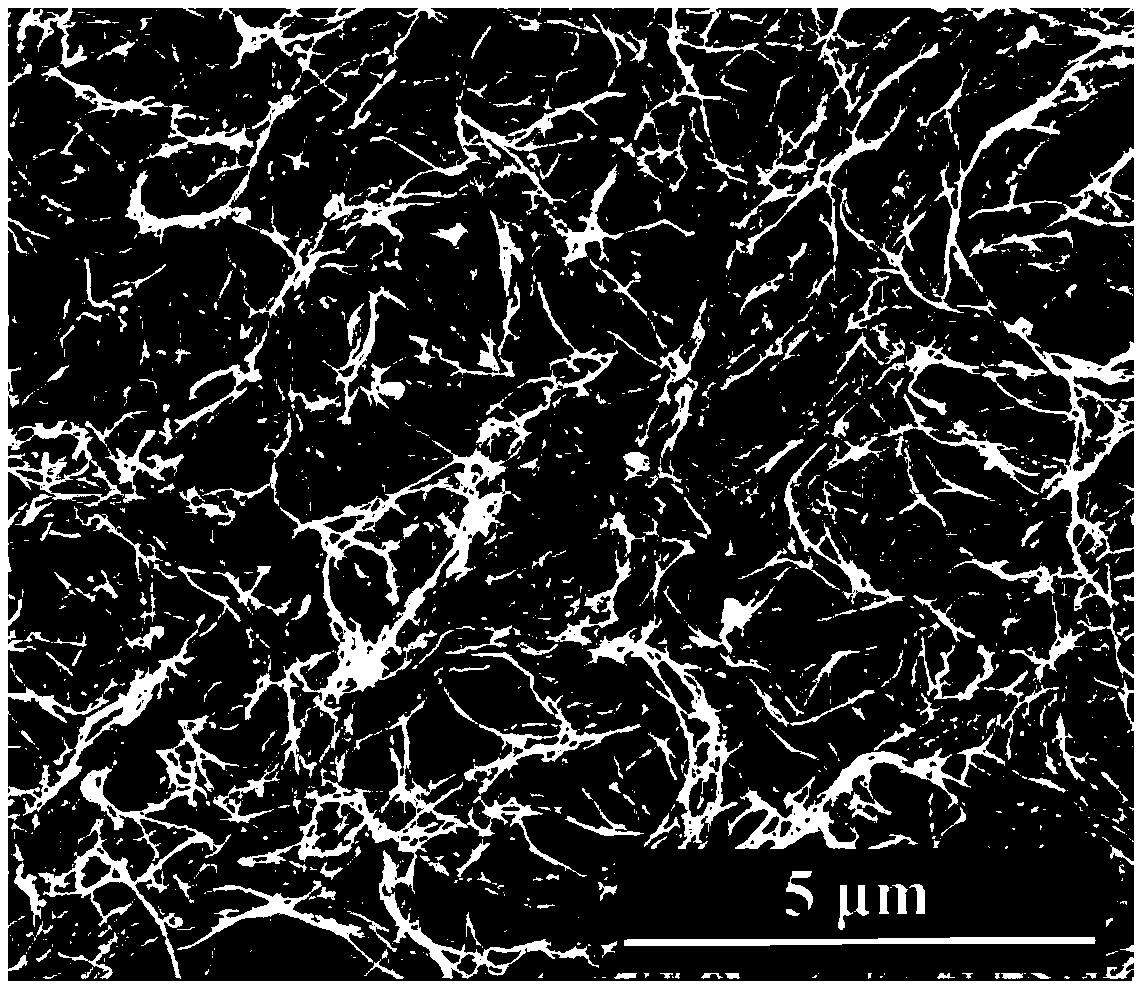

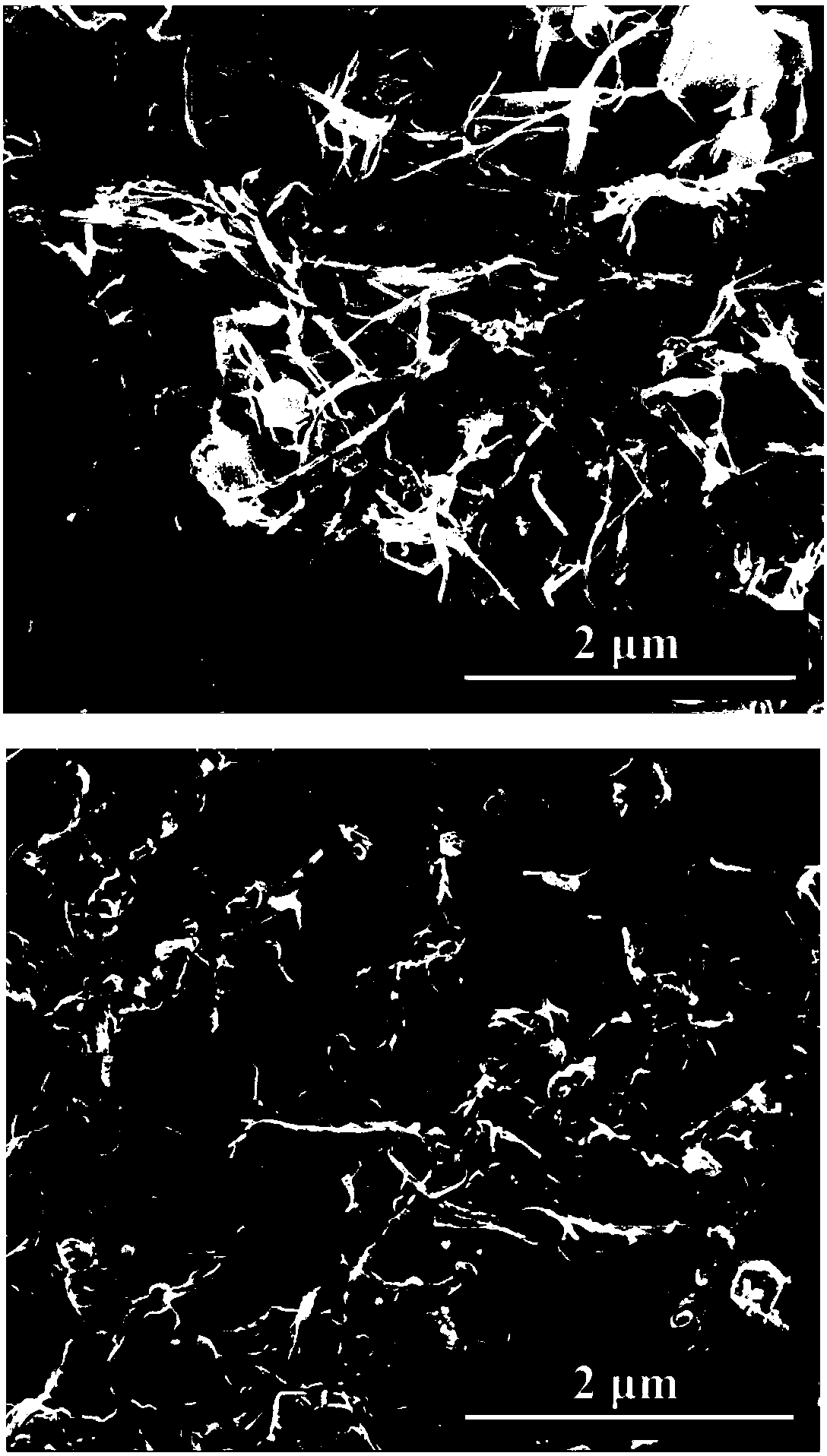

[0038] 1) First, the bacterial cellulose (BC) hydrogel was cut into suitable small pieces, washed with deionized water and soaked for 24 hours, and then freeze-dried to obtain BC airgel. Afterwards, the BC airgel was carbonized (2 h) at 900 °C under an argon atmosphere to obtain carbonized bacterial cellulose, namely carbon nanofibers (CNFs).

[0039] 2) Dissolve 3 mmol of zinc nitrate hexahydrate in 30 mL of methanol, then add 100 mg of carbon nanofibers, and sonicate for 20 min in an ice bath to fully disperse the carbon nanofibers. Afterwards, 12 mmol of dimethylimidazole was dissolved in 10 mL of methanol, and then added to the first solution, stirred gently to ensure that the two solutions were fully mixed, and left to stand for 24 hours. Finally, centrifugal washing (cleaning with methanol) was performed to remove impurities, and the precipitate was dried to obtain a composite material of ZIF-8 and CNFs. In this process, the ratio of dimethylimidazole to zinc nitrate he...

Embodiment 2

[0044] The porous ZIF-8 / CNFs composite material of the present invention and the binder are mixed into a uniform slurry at a weight ratio of 9:1, and coated on the surface of the lithium-ion battery separator to form a modified coating with a certain thickness. The performance of the coating can be further adjusted by adjusting the ratio of the porous ZIF-8 / CNFs composite material to the binder and the thickness of the coating. For example, the thickness of the coating can be controlled at 10-50 μm.

[0045] Then, the lithium-ion battery separator with porous ZIF-8 / CNFs composite coating was applied in the lithium-ion battery, the structure of the battery is as follows Figure 5 shown. The positive and negative electrodes of the lithium-ion battery contain electrode reactive substances. The electrolyte provides a channel for the ion transmission of the battery reaction. The Celgard2400 separator separates the positive and negative electrodes of the battery to prevent the batte...

Embodiment 3

[0054] The commercial product lithium cobaltate pole piece is used as the positive electrode, the lithium sheet is used as the negative electrode, and the diaphragm adopts the ZIF-8 / CNFs composite material coating modified diaphragm of the present invention, and the battery is composed of charging and discharging tests at a rate of 0.5C. The results are as follows: Figure 8 shown. It can be seen that the Li / LiCoO 2 The battery showed good cycle stability, and after 100 cycles at 0.5C, the specific capacity remained at 110mAh g -1 Above, the average Coulombic efficiency exceeds 98%. This test result further proves that the MOF / CNFs composite material of the present invention can improve the cycle stability of the metal lithium negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com