Method for removing sodium chloride from cassava starch polysaccharide-iron complex liquid

A technology of cassava starch and polysaccharide iron, which is applied in the direction of blood diseases, drug combinations, animal feed, etc., can solve the problems of sodium chloride not meeting the use requirements, hidden safety hazards in production, and unsuitable for injection preparations, etc., to achieve easy continuous production , Improve the ability of comprehensive utilization, and promote the effect of iron source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

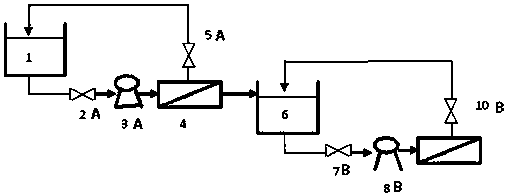

Method used

Image

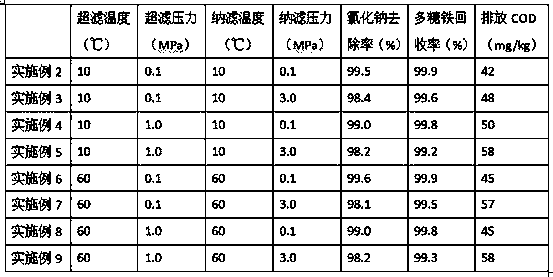

Examples

Embodiment 1

[0026] In the enamel reaction kettle, start stirring, add 750 kg of water and 220 kg of tapioca starch respectively, heat up to 60°C, add 75 kg of 27.5% hydrogen peroxide solution, then raise the temperature to 60°C, keep the constant temperature, and carry out the oxidation reaction for 60 Minutes, add 29% sodium hydroxide seasoning solution, the pH value is 7.6, that is, a cassava starch polysaccharide solution with a weight average molecular weight of 3K-27KDa, continue to heat up to 90°C, keep the constant temperature, and add 39.0% trisodium glutamate at the same time within 3 hours 520 liters of ferric chloride solution and 560 liters of 29.0% sodium hydroxide solution, after the addition, the pH value of the complexation reaction solution was adjusted to 7.3 with 20% hydrochloric acid to obtain a complete reaction solution for the synthesis of tapioca polysaccharide-iron complex.

[0027] In the enamel reaction kettle, start stirring, add water, tapioca starch and hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com