A light lightning protection surface layer and its preparation and use method

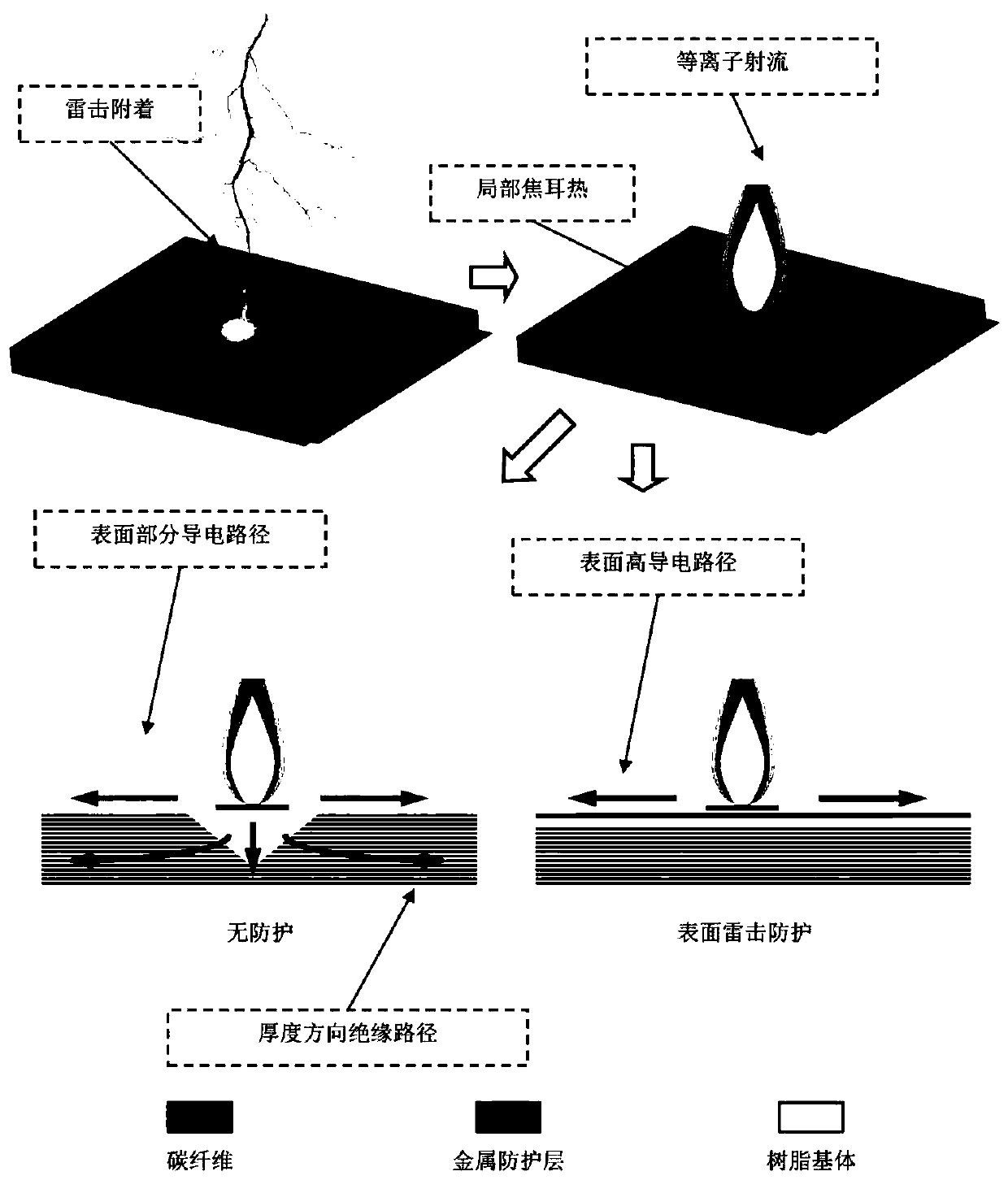

A lightning protection and surface layer technology, applied in the field of composite material manufacturing, to achieve excellent lightning protection performance, good flexibility and materials, and good protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the lightweight lightning protection surface layer of this example is as follows:

[0043] (1-1) Dissolving the phenolic resin in alcohol, the mass ratio of the phenolic resin to ethanol is 0.2. Stir until the phenolic resin is completely dissolved in ethanol;

[0044] (1-2) Add carbon nanotubes and vermiculite to the ethanol solution of phenolic resin. The diameter of carbon nanotubes is 10nm, and the particle size of vermiculite is 300μm; the proportions of carbon nanotubes and vermiculite in the matrix resin are respectively 40% and 10%. A carbon-based dispersant is added to optimize the dispersion effect of graphene, and the mass ratio of the dispersant to carbon nanotubes is (0.2). The above suspension was ultrasonically stirred at room temperature for 30 min at a stirring speed of 200 rpm. Prepare casting solution;

[0045] (1-3) 5 pieces of chemically silver-plated aramid non-woven fabric with a side length of 300 mm;

[0046] (1-4)...

Embodiment 2

[0050] The preparation method of the lightweight lightning protection surface layer of this example is as follows:

[0051] (1-1) The toughened benzoxazine resin was dissolved in chloroform, and the mass ratio of the benzoxazine resin to chloroform was 0.10. Stir until the benzoxazine resin is completely dissolved in chloroform;

[0052] (1-2) Add the expanded graphite to the chloroform solution of the benzoxazine resin, and the ratio of the expanded graphite to the double horse resin is 5%. The above suspension was ball milled at room temperature for 3 h, and the rotational speed of the ball mill was 50 rpm. Prepare casting solution;

[0053] (1-3) Cut 10 pieces of electroless copper-plated ramie felts, the diameter of ramie fibers is 20 μm;

[0054] (1-4) Keep the casting solution in a stirring state, transfer it into the roller brush machine in batches, and brush it on the surface of the electroless copper-plated ramie felt by the roller brush machine. Let stand for 1mi...

Embodiment 3

[0058] The preparation method of the lightweight lightning protection surface layer of this example is as follows:

[0059] (1-1) Polyaryletherketone was dissolved in tetrahydrofuran, and the mass ratio of polyaryletherketone to tetrahydrofuran was 0.05. Stir until the polyaryletherketone is completely dissolved in tetrahydrofuran;

[0060] (1-2) Adding silver nanowires and tin powder into a tetrahydrofuran solution of polyaryletherketone, the proportions of silver nanowires and tin powder in polyaryletherketone are 5% and 50% respectively. A silver dispersant is added to optimize the dispersion effect of the silver nanowires, and the mass ratio of the dispersant to the silver nanowires is 15%. The above suspension was placed at room temperature and stirred ultrasonically for 10 min at a stirring speed of 500 rpm. Prepare an impregnation solution;

[0061] (1-3) Cut 2 pieces of nickel-plated carbon felt, and the diameter of the nickel-plated carbon fiber is 15 μm.

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com