Fruit and vegetable preservative paper and preparation method thereof

A fruit and vegetable preservation and paper pulp technology, applied in the field of preservation, can solve the problems of poor preservation effect of fresh-keeping paper, etc., and achieve the effect of improving the quality of fruits and vegetables, prolonging the preservation period of fruits and vegetables, and prolonging the preservation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

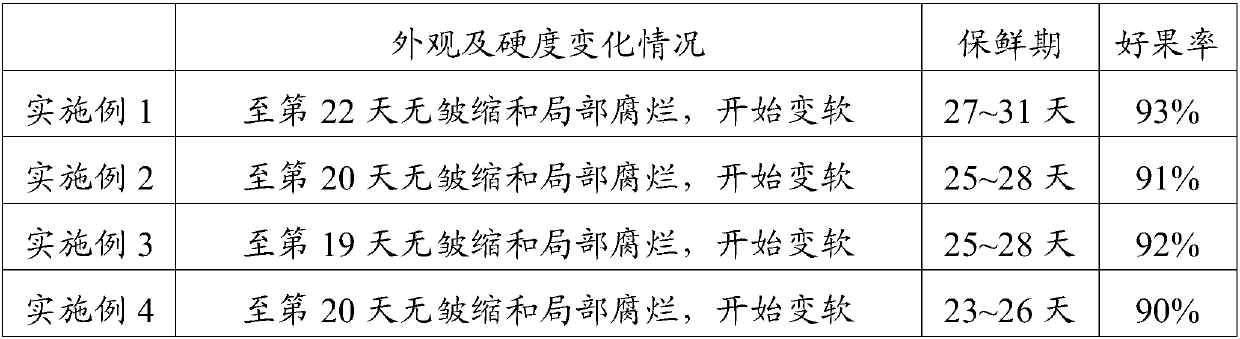

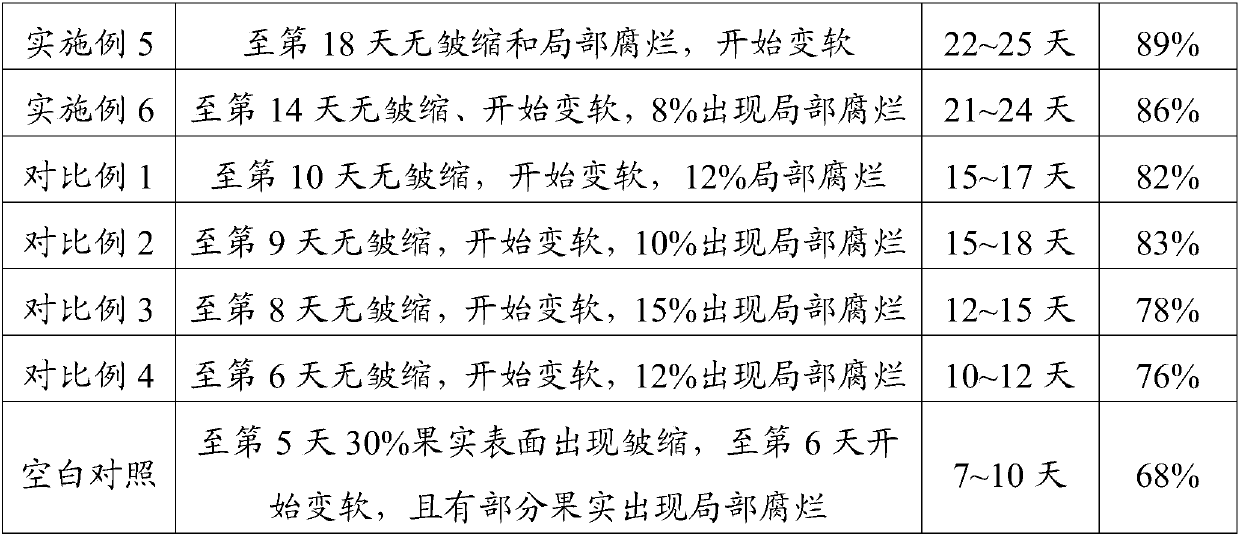

Examples

preparation example Construction

[0041] Another embodiment of the present invention provides a method for preparing the above-mentioned fruit and vegetable fresh-keeping paper, including the following steps S001-S003:

[0042] S001: Thinning the pulp into a slurry suspension.

[0043] S002: Add ethylene absorbent and antifungal agent to the slurry suspension and mix well.

[0044] S003: Add hydrophilic resin and mix evenly; then cut and make paper to obtain fresh-keeping paper for fruits and vegetables.

[0045] Specifically, the hydrophilic resin is soaked in water at room temperature for 1 to 3 hours, prepared into an aqueous solution of the hydrophilic resin, and then added to the above-mentioned slurry suspension containing ethylene absorbent and antifungal agent, and stirred at a stirring speed of 600 ~800 rpm.

[0046] The preparation method of the above-mentioned fresh-keeping paper for fruits and vegetables is simple and easy to implement, requires low technological conditions, requires low cost, an...

Embodiment 1

[0049] Provide raw materials, including by weight percentage: 85% pulp (including 85% waste paper pulp + 15% hardwood virgin pulp), 10% hydrophilic resin (80% polyvinyl alcohol 1788 + 20% styrene acrylate), 2% ethylene absorbent and 3% antifungal agent (50% sodium diacetate + 30% carson + 12% methylparaben + 8% potassium sorbate), the active ingredient of ethylene absorbent is potassium permanganate and silver chloride, and the weight ratio of potassium permanganate to silver chloride is 9:1, and the carrier is composed of 25 parts of zeolite + 15 parts of diatomaceous earth + 40 parts of bentonite.

[0050] Dissolve the pulp into slurry suspension by conventional papermaking process, add ethylene absorbent, stir for 20 minutes, then add antifungal agent, stir for 20 minutes, and mix well.

[0051] Soak polyvinyl alcohol and styrene acrylate with appropriate amount of water for 2 hours at room temperature respectively, prepare polyvinyl alcohol aqueous solution and styrene acr...

Embodiment 2

[0054] Provide raw materials, including by weight percentage: 80% pulp (including 95% waste paper pulp + 5% hardwood virgin pulp), 15% hydrophilic resin (80% polyvinyl alcohol 1788 + 20% styrene acrylate), 2% ethylene absorbent and 3% antifungal agent (50% sodium diacetate + 30% carson + 12% methylparaben + 8% potassium sorbate). The active ingredients of the ethylene absorbent are potassium permanganate and silver chloride, and the weight ratio of potassium permanganate to silver chloride is 10:1, and the carrier is composed of 25 parts of zeolite + 15 parts of diatomite + 40 parts of bentonite .

[0055] Dissolve the pulp into slurry suspension by conventional papermaking process, add ethylene absorbent, stir for 20 minutes, then add antifungal agent, stir for 20 minutes, and mix well.

[0056] Soak polyvinyl alcohol and styrene acrylate with appropriate amount of water for 2 hours at room temperature respectively, prepare polyvinyl alcohol aqueous solution and styrene acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com