Preparation method for nanoscale negative structure with high depth-to-width ratio and high conformality

A high-aspect-ratio, nanoscale technology, applied in the field of optics and biology, can solve the problems that conformal filling cannot be satisfied, it is difficult to ensure the preparation of high-aspect-ratio and high-conformity nanoscale negative structure, and achieve low surface roughness, The effect of small structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0038] (1) Provide a substrate: select a single crystal silicon substrate, and first use acetone to ultrasonically clean it for 300 seconds, then use isopropanol to ultrasonically clean it for 300 seconds, and blow it dry with nitrogen.

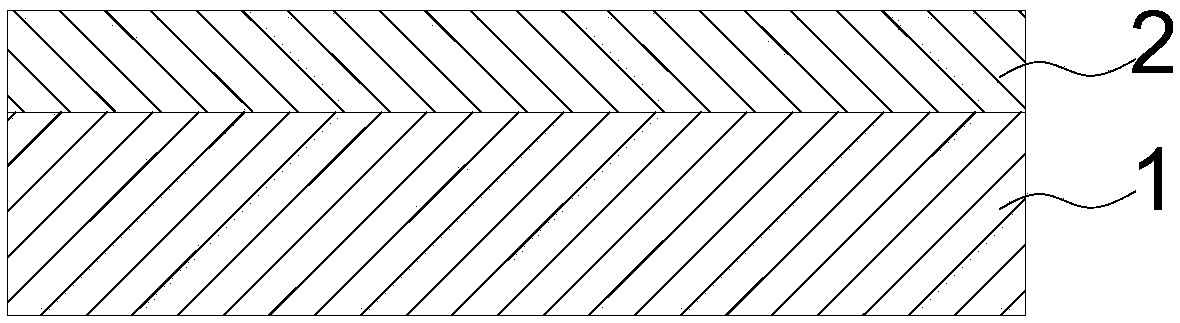

[0039] As shown in Figure (1), first drop 6% HSQ on the substrate and spin coat it at 4000r / s for 60s.

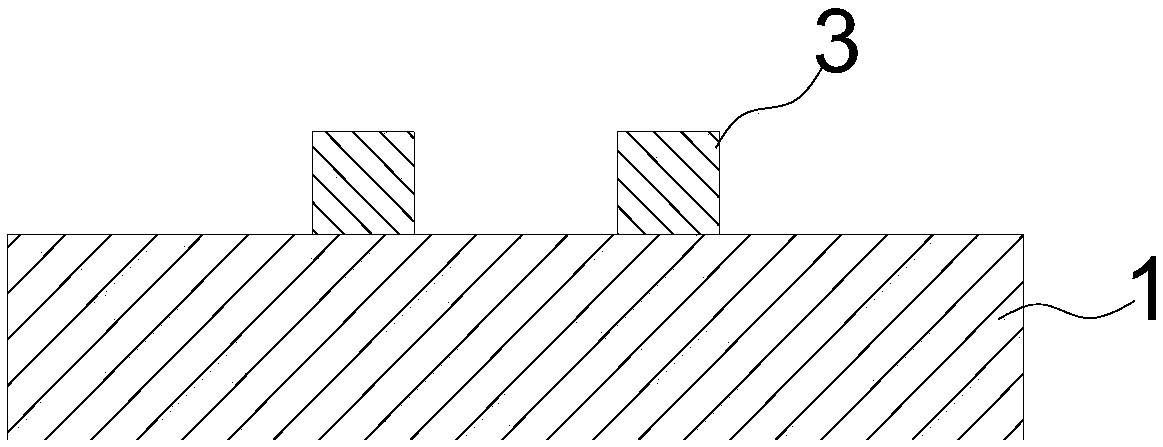

[0040] As shown in the effect diagram in Figure (2), the electron beam exposure equipment Raith 150two is used to expose HSQ at a fixed point with a high voltage of 30KV and a 30μm aperture, and the exposed film is developed in a sodium hydroxide developer for 60s, and then used Rinse with IPA for 60 s and blow dry with nitrogen.

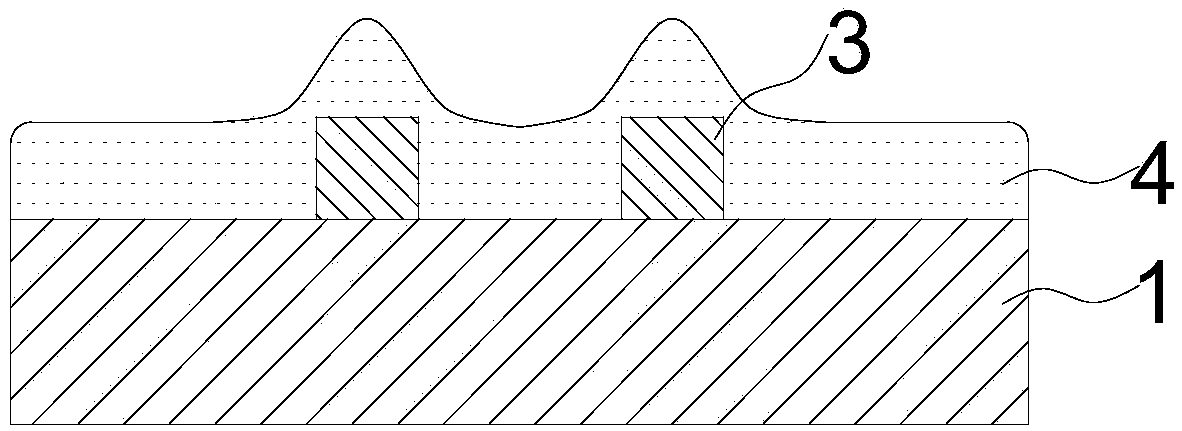

[0041] As shown in Figure (3), magnetron sputtering was used to sputter and coat the film for 280 seconds under the conditions of bias voltage 80V, current 0.8A, and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com