Coating for screws of wheel hubs for trucks

A hub and screw technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of troublesome and dangerous operation, high manufacturing cost, easy to rust, etc., and achieve convenient operation, non-toxic and pollution-free cost, method reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

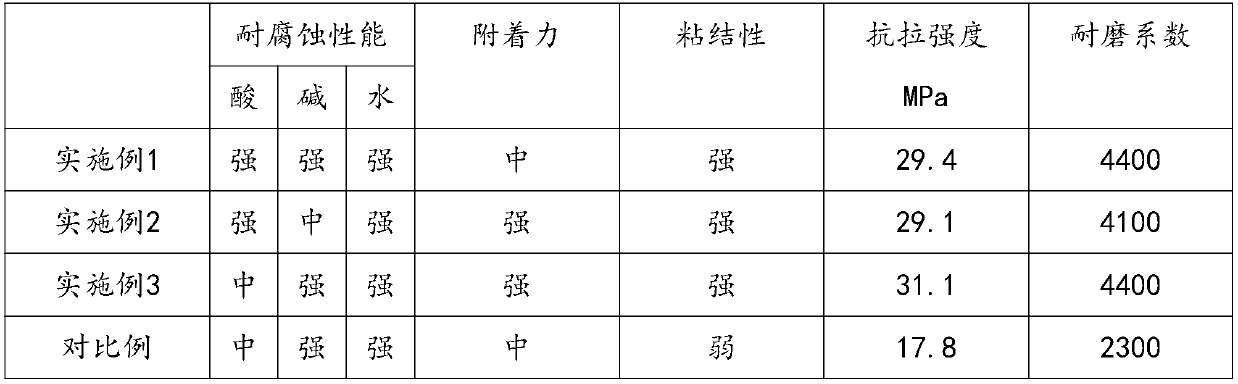

Examples

Embodiment 1

[0025] A coating used for the screws of the wheel hub of a truck, characterized in that: it is made of the following materials by weight,

[0026] 11 parts of resin, 126 parts of nylon, 1 part of sodium tripolyphosphate, 4 parts of dicumyl peroxide, 7 parts of modified fluorite, 2 parts of polyoxypropylene glycol, 2 parts of propylene glycol adipate, 2- 1 part of hydroxy-4-n-octyloxybenzophenone, 2 parts of triphenyl phosphite, 4 parts of polyurethane acrylate, 7 parts of polyester polyol, 3 parts of polyisobutylene, 1 part of europium trifluoroacetylacetonate, 8 parts of foaming agent, 8 parts of anti-aging agent, 5 parts of biomass auxiliary materials, 20 parts of deionized water;

[0027] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0028] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0029] The defoamer is one of...

Embodiment 2

[0040] A coating used for the screws of the wheel hub of a truck, characterized in that: it is made of the following materials by weight,

[0041] 17 parts of resin, 1210 parts of nylon, 4 parts of sodium tripolyphosphate, 9 parts of dicumyl peroxide, 13 parts of modified fluorite, 7 parts of polyoxypropylene glycol, 7 parts of propylene glycol adipate, 2- 5 parts of hydroxy-4-n-octyloxybenzophenone, 6 parts of triphenyl phosphite, 9 parts of polyurethane acrylate, 12 parts of polyester polyol, 8 parts of polyisobutylene, 3 parts of europium trifluoroacetylacetonate, 15 parts of foaming agent, 15 parts of anti-aging agent, 10 parts of biomass auxiliary materials, 27 parts of deionized water;

[0042]The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0043] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0044] The defoamer i...

Embodiment 3

[0055] A coating used for the screws of the wheel hub of a truck, characterized in that: it is made of the following materials by weight,

[0056] 14 parts of resin, 128 parts of nylon, 3 parts of sodium tripolyphosphate, 6 parts of dicumyl peroxide, 11 parts of modified fluorite, 5 parts of polyoxypropylene glycol, 5 parts of propylene glycol adipate, 2- 4 parts of hydroxy-4-n-octyloxybenzophenone, 3 parts of triphenyl phosphite, 7 parts of polyurethane acrylate, 9 parts of polyester polyol, 6 parts of polyisobutylene, 2 parts of europium trifluoroacetylacetonate, 14 parts of foaming agent, 12 parts of anti-aging agent, 8 parts of biomass auxiliary materials, 23 parts of deionized water;

[0057] The resin is one of polyethylene resin, alkyd resin, epoxy resin, urea-formaldehyde resin, polyamide resin;

[0058] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0059] The defoamer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com