Preparation method of sintered nd-fe-b magnet surface wearproof anticorrosive coating

A kind of anti-corrosion coating, NdFeB technology, applied in the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of unsatisfactory protection effect, high equipment investment cost, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

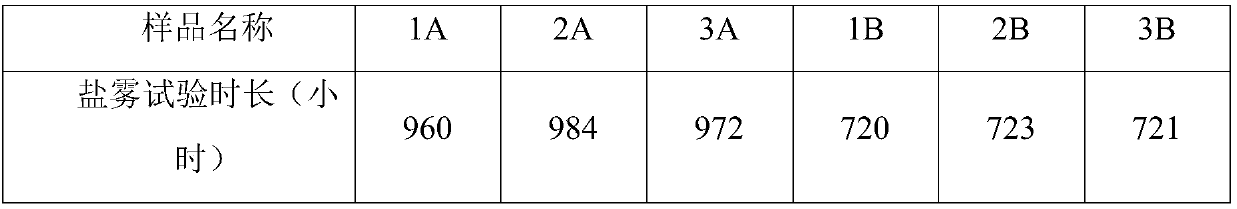

Examples

Embodiment 1

[0023] A method for preparing a wear-resistant and anti-corrosion coating on the surface of a sintered NdFeB magnet is carried out according to the following steps:

[0024] (1) Preparation of wear-resistant and anti-corrosion coating materials: first, the organic polymer materials polypropylene, polyethylene and polystyrene are prepared in a weight ratio of 1:1:2; then the nano-ceramic materials boron nitride, nitride Aluminum and titanium nitride are prepared in a weight ratio of 1:3:2, and the size of the nano-ceramic material is 10nm; finally, the prepared organic polymer material and nano-ceramic material are prepared in a weight ratio of 3:0.5; at the same time Add 0.1% accelerator for polyurethane adhesive, 0.2% aromatic amine curing agent and 0.3% silicate lubricant to the total weight of organic polymer materials and nano-ceramic materials; Layer materials are mixed thoroughly.

[0025] (2) Coating treatment: first, preheat the sintered NdFeB magnet to 60°C, and then...

Embodiment 2

[0028] A method for preparing a wear-resistant and anti-corrosion coating on the surface of a sintered NdFeB magnet is carried out according to the following steps:

[0029] (1) Preparation of wear-resistant and anti-corrosion coating materials: first, the organic polymer materials polypropylene, polyethylene and polystyrene are prepared in a weight ratio of 2:3:3; then the nano-ceramic materials boron nitride, nitride Aluminum, zirconia and titanium nitride are prepared in a weight ratio of 1:2:5:3, wherein the size of the nano-ceramic material is 50nm; then the prepared organic polymer material and nano-ceramic material are prepared in a weight ratio of 4: 1 is prepared; then add 0.3% fast solid acrylate structural adhesive accelerant, 0.5% alicyclic amine curing agent and 0.5% phosphate Lubricant; Finally, fully mix the wear-resistant and anti-corrosion coating materials.

[0030] (2) Coating treatment: first, preheat the sintered NdFeB magnet to 80°C, and then use the ele...

Embodiment 3

[0033] A method for preparing a wear-resistant and anti-corrosion coating on the surface of a sintered NdFeB magnet is carried out according to the following steps:

[0034] (1) Preparation of wear-resistant and anti-corrosion coating materials: first, the organic polymer materials polypropylene, polyethylene and polystyrene are prepared in a weight ratio of 3:5:4; then zirconia is prepared as a nano-ceramic material, The size of the nano-ceramic material is 100nm; the organic polymer material and the nano-ceramic material are prepared in a weight ratio of 5:2; then 0.5% of the total weight of the organic polymer material and the nano-ceramic material is added to it. Accelerator for acrylate structural adhesive, 0.8% aromatic amine curing agent and 0.7% silicate lubricant; finally, fully mix the wear-resistant and anti-corrosion coating material.

[0035] (2) Coating treatment: first, preheat the sintered NdFeB magnet to 100°C, and then use the electrostatic spraying process t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com